Mechanical Installation – Part 1: Tiles

Version: 1.0 ───

45XPlanar

7.2.2Screws and locating pins

Ensure correct length of the screws and locating pins

Make sure that the screws and locating pins have the correct length

in order to obtain a flat tile surface and to avoid damage to the tile.

Ensure correct tolerance of the locating pins

The D5locating pins must have an m6 tolerance.

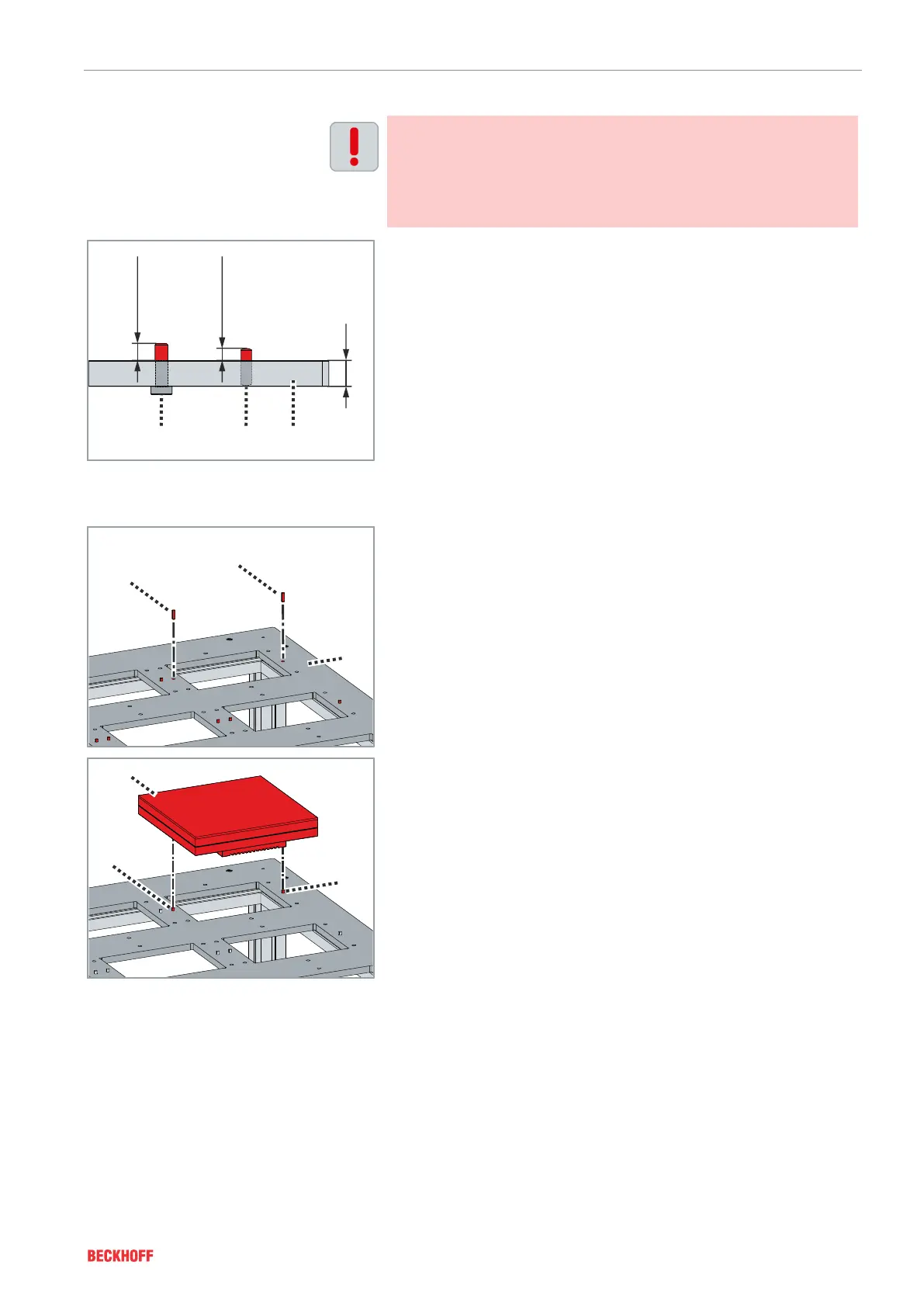

The length of the screws[1] and locating pins[2] for fixing the tiles

depends on the height X of the machine bed[3].

Beckhoff recommends the following screw depths in the tile:

• The M6screws[1] for fastening the tiles should protrude be-

tween 6 and 9 mm from the machine bed[3].

• The D5locatingpins[2] for fastening the tiles should protrude

between 3 and 5 mm from the machine bed[3].

For further information on the maximum screw depths into the tile,

please refer to the chapter on "Dimensional drawings", [Page34].

7.2.3Mounting

7.2.3

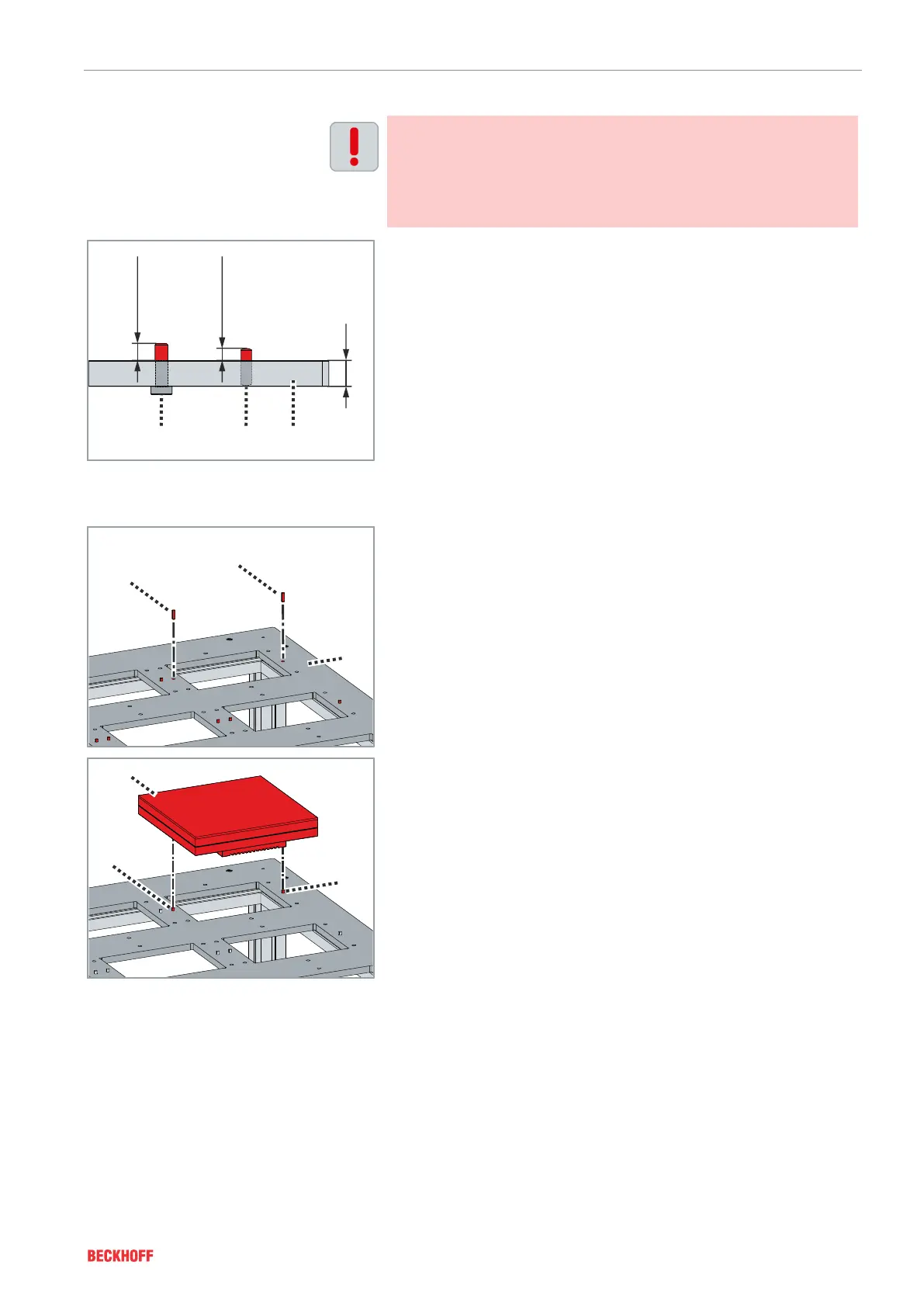

► Insert all locating pins[1] into the machine bed[2]

► Position the tile[1] with the locating pin hole and the elongated

hole on the locating pins[2]

Loading...

Loading...