6 - 9

Periodic maintenance and adjustment

EN

6

Checking the spark plugs

The spark plugs are important engine

components, which should be checked

periodically, preferably by a Benelli dealer.

Since heat and deposits will cause any

spark plug to slowly erode, they should

be removed and checked in accordance

with the periodic maintenance and lubri-

cation chart. In addition, the condition of

the spark plugs can reveal the condition

of the engine.

The porcelain insulator around the center

electrode of each spark plug should be a

medium-to-light tan (the ideal color when

the vehicle is ridden normally), and all

spark plugs installed in the engine should

have the same color.

If any spark plug shows a distinctly die-

rent color, the engine could be operating

improperly.

Do not attempt to diagnose such pro-

blems yourself. Instead, have a Benelli de-

aler check the vehicle.

If a spark plug shows signs of electrode

erosion and excessive carbon or other de-

posits, it should be replaced.

Before installing a spark plug, the spark

plug gap should be measured with a wire

thickness gauge and, if necessary, adju-

sted to specication.

Clean the surface of the spark plug gasket

and its mating surface, and then wipe o

any grime from the spark plug threads.

TIP

If a torque wrench is not available when

installing a spark plug, a good estimate

of the correct torque is 1/4–1/2 turn past

nger tight.

However, the spark plug should be tighte-

ned to the specied torque as soon as

possible.

Specied spark plug:

RG4HC

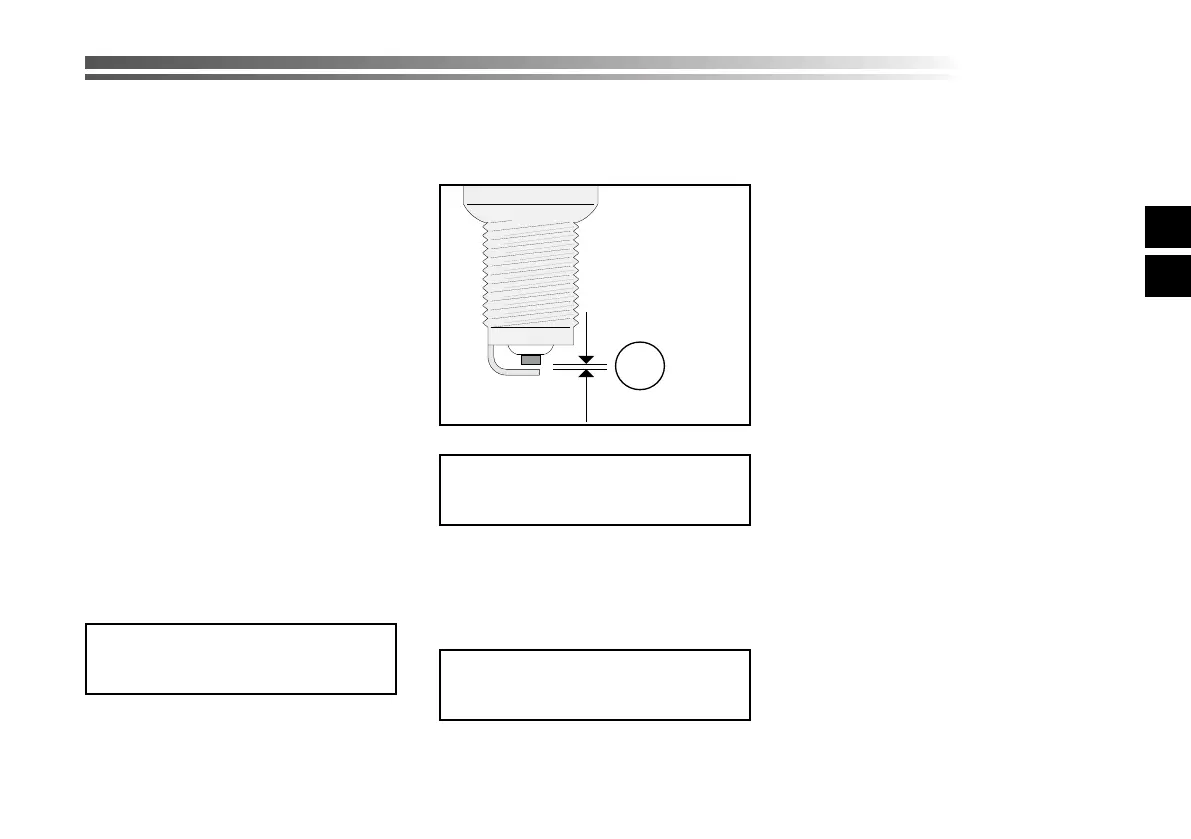

1. Spark plug gap

Spark plug gap:

0.7–0.8 mm

Tightening torque:

15 N·m

47 ◙

Lid screws

clutch

Check T T T T T

48 ◙

Catalytic

converter

Check for faults/leaks

I I I I I

No maintenance required. In case of malfunction replace.

49 ◙

Canister

Oil suction filter

Check for faults/leaks

I I I I I

No maintenance required. In case of malfunction replace.

50 ◙

Brake/clutch

hoses

Check for faults/leaks I I I I I I I

51 ◙

Parts and wires

subject to

movement

Check/Replacement

I I I I I I I

Replace if damaged.

52 ◙

Check/Replacement I I I I

53 ◙

Wheel spokes

front/rear

Check II I

No.

Maintenance

intervention or control

0 Km

Pre-delivery

1.000 Km

1°

service

7.000 Km

2°

service

13.000 Km

3°

service

19.000 Km

4°

service

25.000 Km

5°

service

Annual

inspection

Part

GAP

1

Loading...

Loading...