June 2004 - 9507EI/5

1-14

2 to 9 Tonne Dumper Instruction Manual

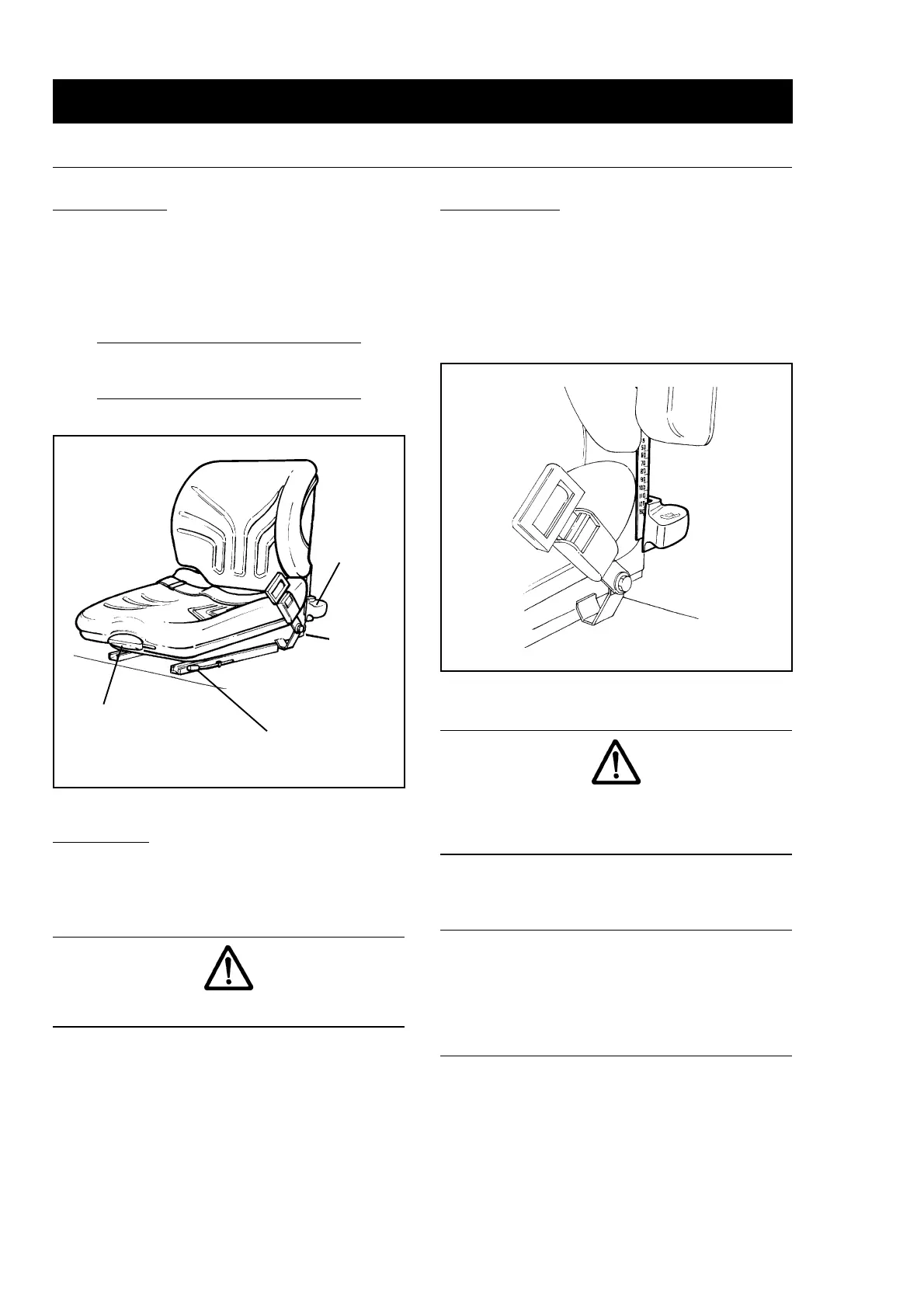

Seat Operating Instructions

Angle Adjustment

The seat backrest is adjustable for angle, this is achieved by

lifting the lever (1) at the front of the seat cushion and sliding the

seat cushion forwards/backwards.

Release the lever and ensure the seat runners engage in one

of the preset locking positions.

4, 5, 6, 7 and 9 Tonne Machines Will Not

START Unless Operator is Sitting on the Seat

Seat Movement

On all machines the operator is able to adjust the seat in the fore-

aft direction by lifting knob (2) and sliding seat to desired

position, then releasing the knob to lock the seat into position.

Do Not Adjust Seat While the Machine Is Moving

Weight Adjustment

The seat may be adjusted for drivers weight by sliding lever (3)

downwards to the relevant weight position, as indicated by the

scale on the side of the seat.

To return lever to top of scale push the lever fully downwards

to the bottom of the scale and then lift lever to the top.

The seat MUST always be adjusted to suit weight of EACH

Operator. Incorrect weight adjustment may inhibit operation

of the seat switch fitted on 4, 5, 6, 7 and 9 tonne dumpers

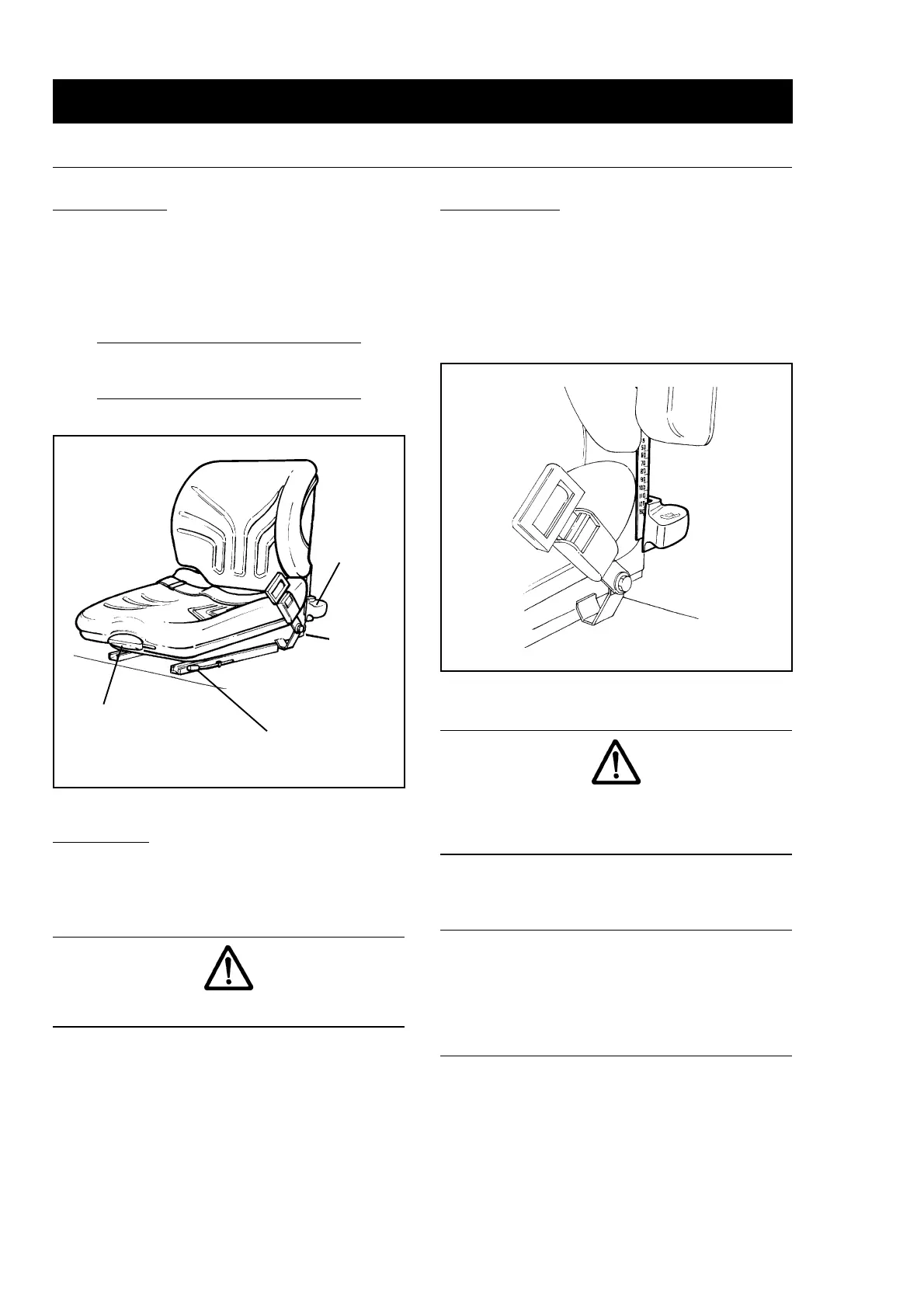

Start Inhibitors - 2 and 3 Tonne Machines

The operator must be correctly positioned on the drivers seat

and the clutch pedal must be fully depressed to operate the start

inhibitor switch, before the engine can be started.

Start Inhibitors - 4, 5, 6, 7 and 9 Tonne Machines

z To help prevent accidents a safety system is controlled by a

switch operated by the weight of the Operator on seat.

z The engine cannot be started unless the Operator is sitting

on the seat and the forward/reverse lever is in neutral.

Incorrect weight adjustment may inhibit starting of

the engine due to the operation of the seat switch

Seat Operating Instructions

(2) Seat

Movement

(3) Weight

Adjustment

(1) Angle

Adjustment

Loading...

Loading...