June 2004 9507EM/5

2-38

2 to 9 Tonne Dumper Instruction Manual

Maintenance

Finally

z Grease all pivot pins, bearings and grease points. Remove

any blocks and jacks from around dumper.

z Re-connect battery.

z Start engine and run at idle, check for any hydraulic leaks.

The skip may act unpredictably while air exists in the

hydraulic circuit Before operating skip ensure area

around skip is clear of obstructions and people

z To remove air from the hydraulic circuit operate skip ram to

its extremes of movement until the operation is smooth.

z If operation of control valve lever does not match direction

of movement of the skip; stop engine, operate the control

valve lever to remove trapped air and pressure in hydraulic

circuit, swap over hose connections .

z Restart engine and check operation of skip again, check for

and correct any hydraulic leaks.

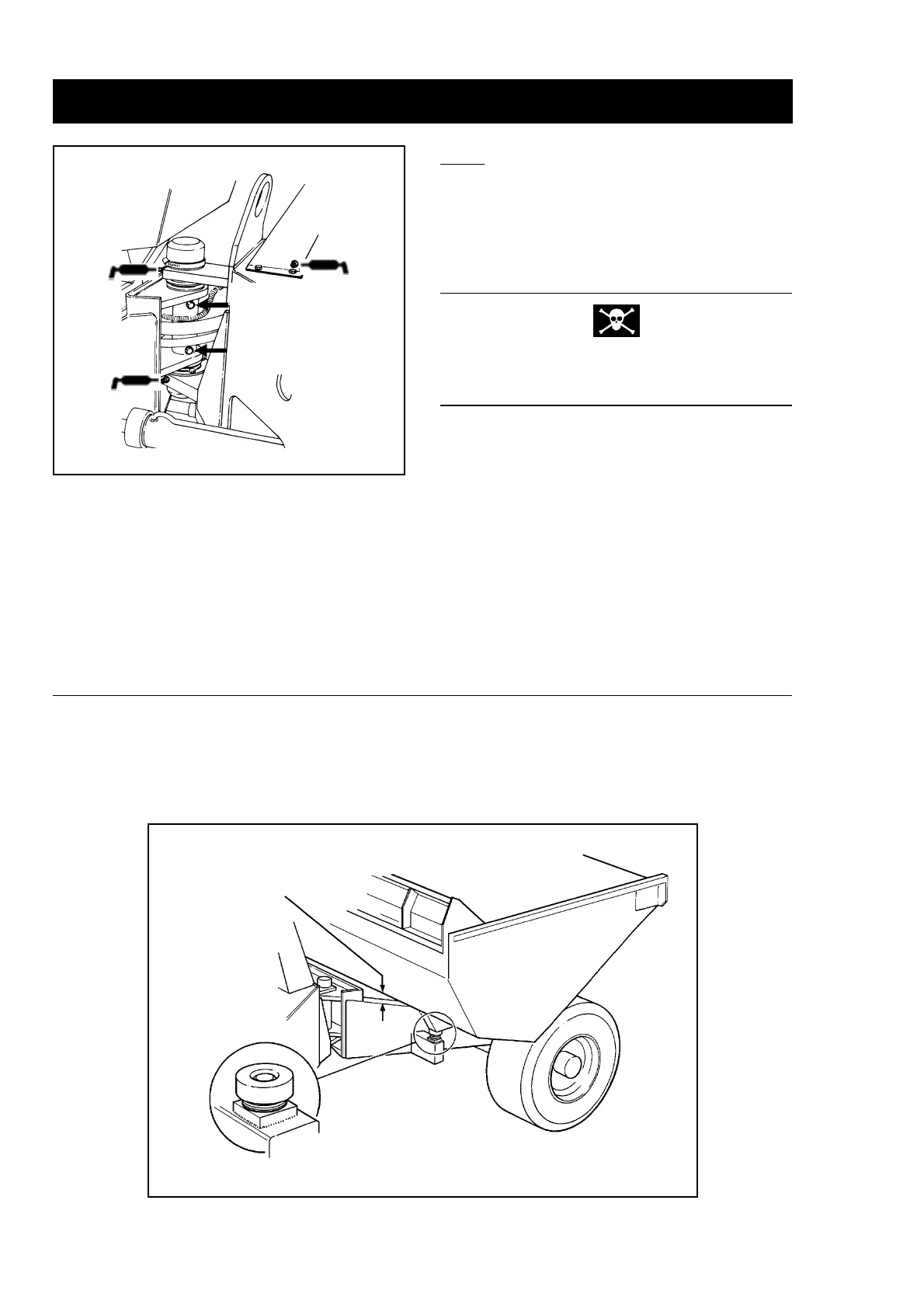

Centre Pivot

Pin Lock

Screws

Centre Pivot

Pin Lock

Screws

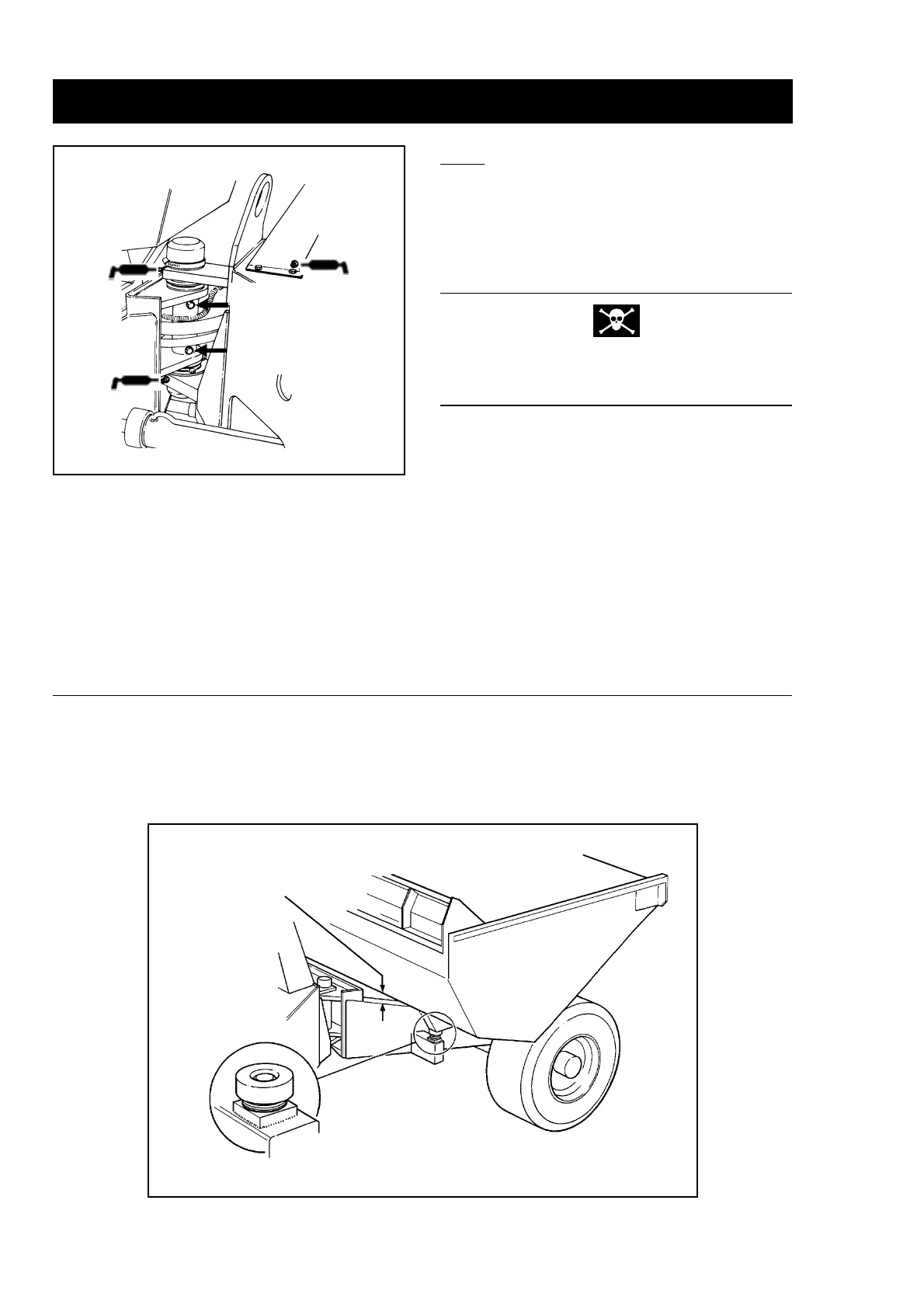

The skip has 2 adjustment stops located on the front frame

outrigger supports. These stops require adjustment to ensure the

skip is supported by the chassis and does not rest on the

hydraulic ram

Straight Skip Adjustment

The clearance between the chassis and skip at the closest point

should be a minimum of 10mm (0.39"). Adjust the height by

shimming as shown below.

Skip Adjusting Screw,

Packers and Shims

Adjust Gap to 10mm (0.39")

Between Underside of Skip

and Chassis Side Member

Loading...

Loading...