June 2004 - 9507EI/5

1-23

2 to 9 Tonne Dumper Instruction Manual

Hydraulic System

The hydraulic system provides power to operate the vehicle

steering and to power the skip elevation.

All dumpers other than the turntable models have a similar

hydraulic circuit layout (see circuit diagrams) and all the

components other than the skip ram, steering ram and the

hydraulic pump are common.

In the case of the turntable dumpers, additional rams are

required to slew the skip to the left or right positions.

The system comprises an engine driven hydraulic pump drawing

oil from a tank located inside the chassis. The tank is fitted with

a suction strainer, an oil level gauge, and a filler/breather cap.

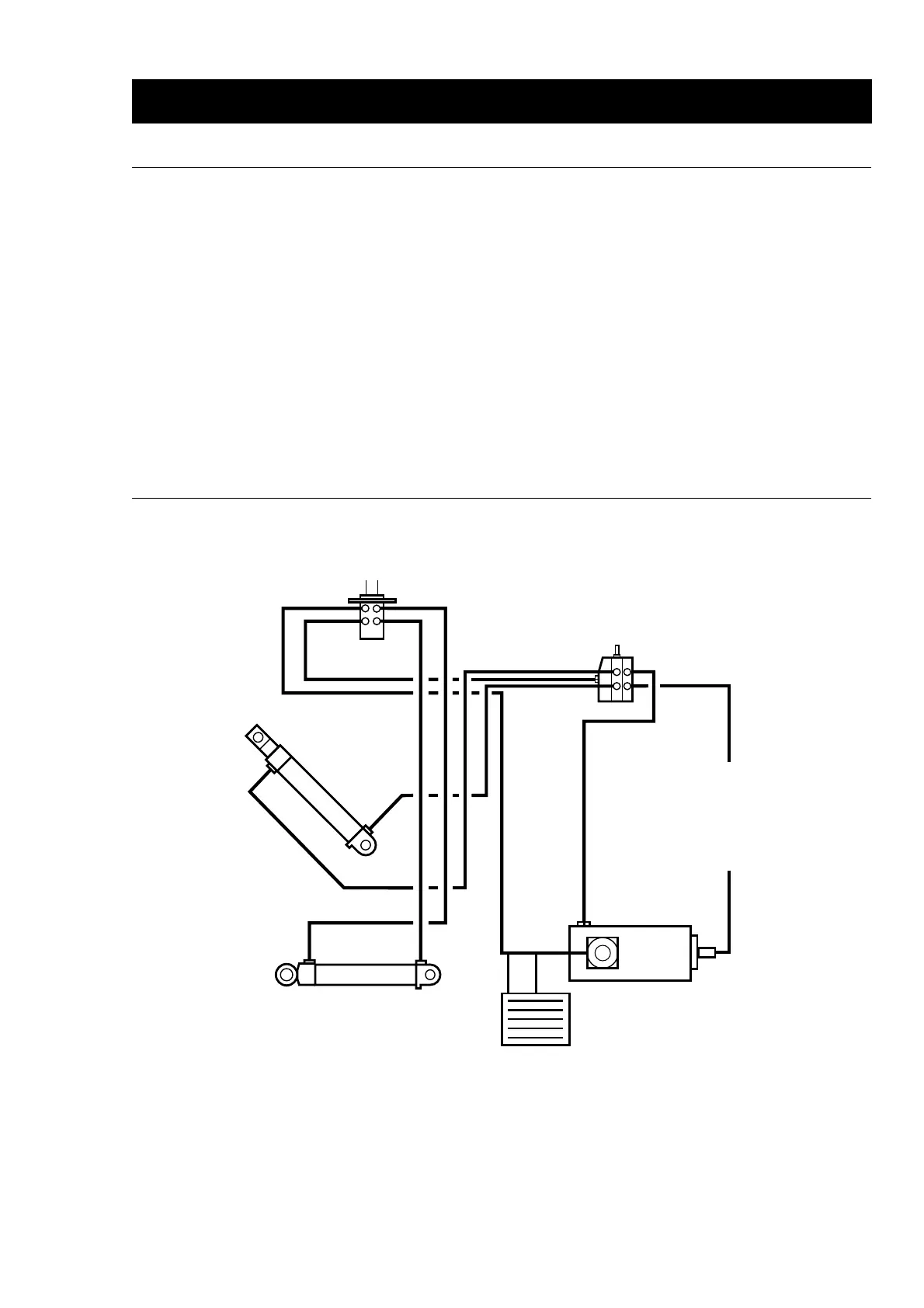

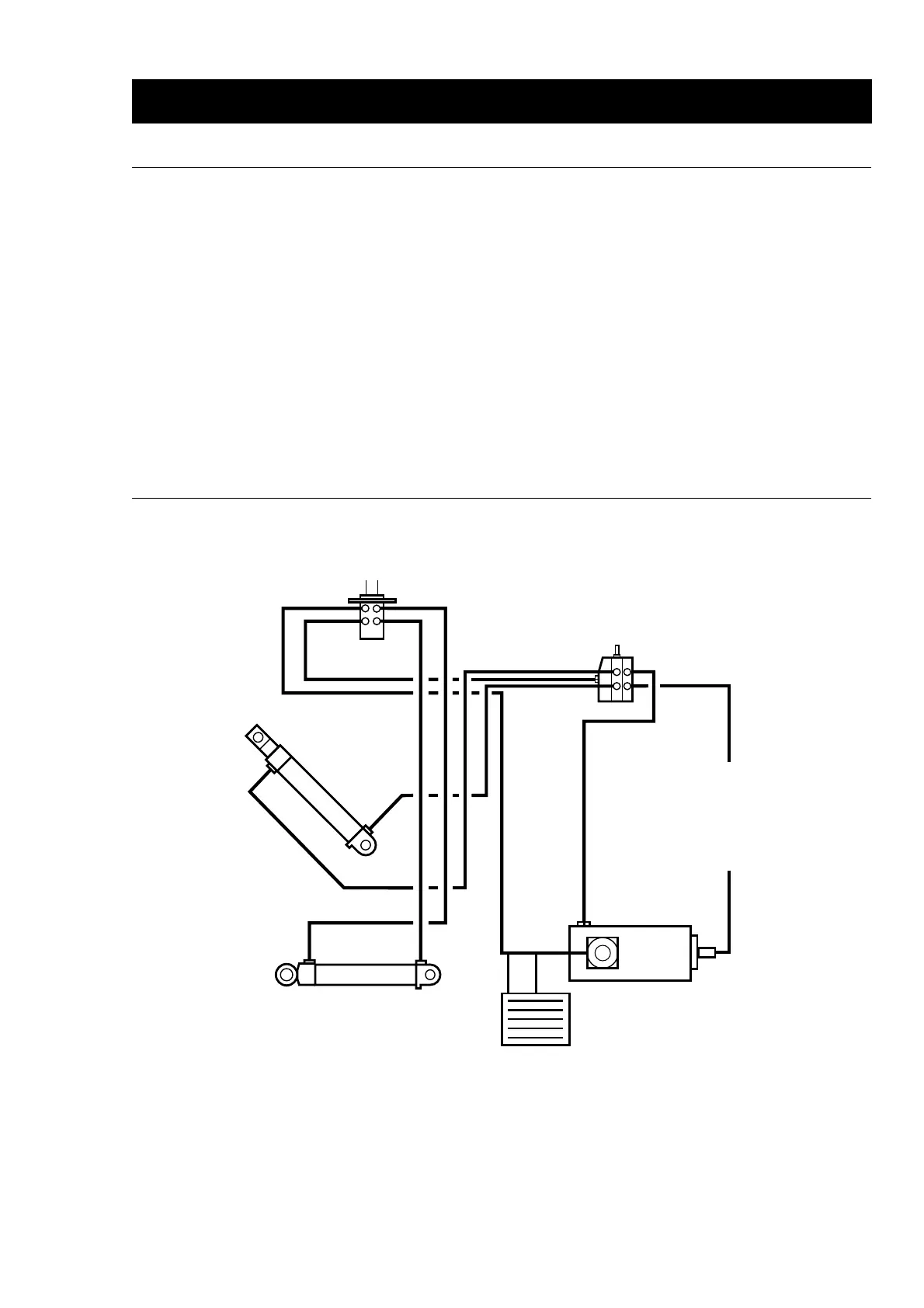

2 to 4 Tonne Hydraulic Circuit

Orbitrol

Control Valve

Hydraulic Tank

Steering Ram

Skip Ram

Hydraulic

Oil Cooler

- if fitted

From

Pump

To

Pump

The pump generates a maximum pressure of 150 bar (2200psi)

on the standard skip dumpers and 170 bar (2500psi) on the

turntable skip dumpers. The system is protected by a relief valve

in the control valve which is set at the same pressure. A return

line filter is fitted to the circuit and is either of the replaceable

cartridge type (Steel Tanks) or the replaceable element type

(Plastic Tanks)

Steering of the dumper is by means of a single hydraulic ram

connecting the front and rear frames, the oil supply to the ram

is controlled by an Orbitrol hydrostatic steering unit. The unit

receives oil via a carry over port in the 3 way control valve and

meters oil to the steering ram as the steering wheel is turned, at

all times.

How the Hydraulics Function

Straight Skips

Loading...

Loading...