June 2004 9507EM/5

2-20

2 to 9 Tonne Dumper Instruction Manual

Maintenance

Brakes

Arrangements

Models 2 - 4 tonne have NEWAGE axles with oil immersed

totally enclosed multi-plate brakes (4 plate front and 2 plate rear).

Some models have braking on front axle only, see Technical Data

section, others have brakes on both front and rear axles operating

on independent hydraulic circuits giving dual circuit safety. 5, 6

and 7 tonne models have Newage axles and dual brake circuits

with 2 plates front and rear. The 9 tonne model uses the PD70 ITL

axles with dual brake circuits and 3 plates.

The brake system is charged with mineral oil, NOT BRAKE

FLUID, via a fluid reservoir which is integral with the brake

master cylinder. In the case of a single braked axle the master

cylinder is of the single type whereas on the 2 braked axle

system a tandem master cylinder is used to provide 2 completely

independent circuits.

Normally adjustment of the brakes is unnecessary due to the

automatic compensation which is built into the brake design,

but bleeding of the system may be necessary on occasions if

pipework is damaged causing system leakage.

Under NO circumstances allow conventional BRAKE FLUID

to be added to the system and NEVER purge the system and

refill with brake fluid, otherwise damage will occur to all

the rubber sealing components in the brake system

The brakes on the range of machines provide means of effective

braking with minimum maintenance, but it is vital during

maintenance on the machine that the general condition of the

system. i.e. pipework, pedal operation, fluid level and general

oil tightness is checked and deficiencies corrected immediately

Failure to do so Could Result in an Accident

Brake Bleeding

Ensure only mineral hydraulic oil is used to bleed braking system

Procedure

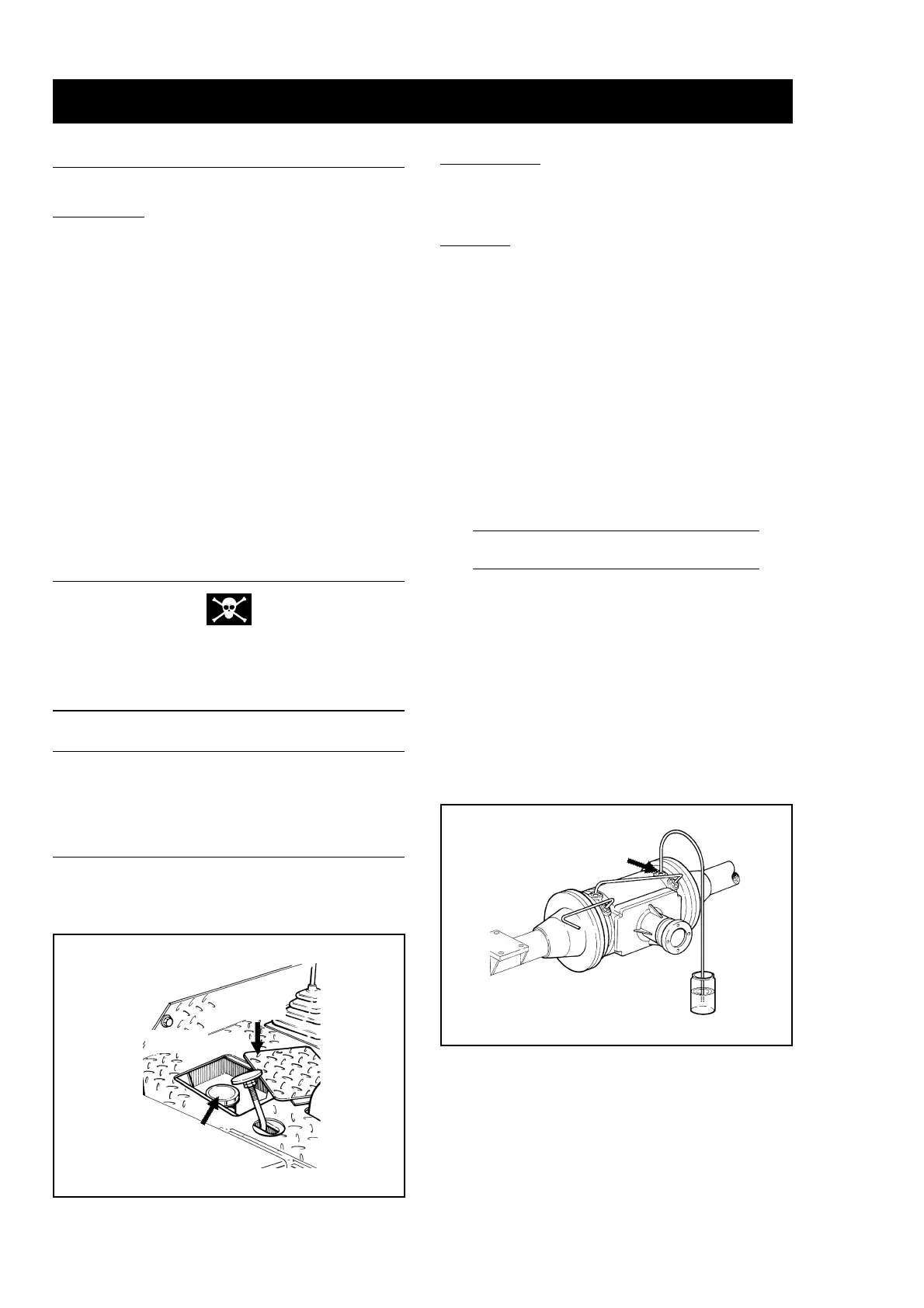

z Remove master cylinder floor plate cover, 2 to 4 tonne, and

the reservoir cap. The reservoir is located under the seat support

on the 5, 6, 7 and 9 tonne. Ensure the reservoir is full.

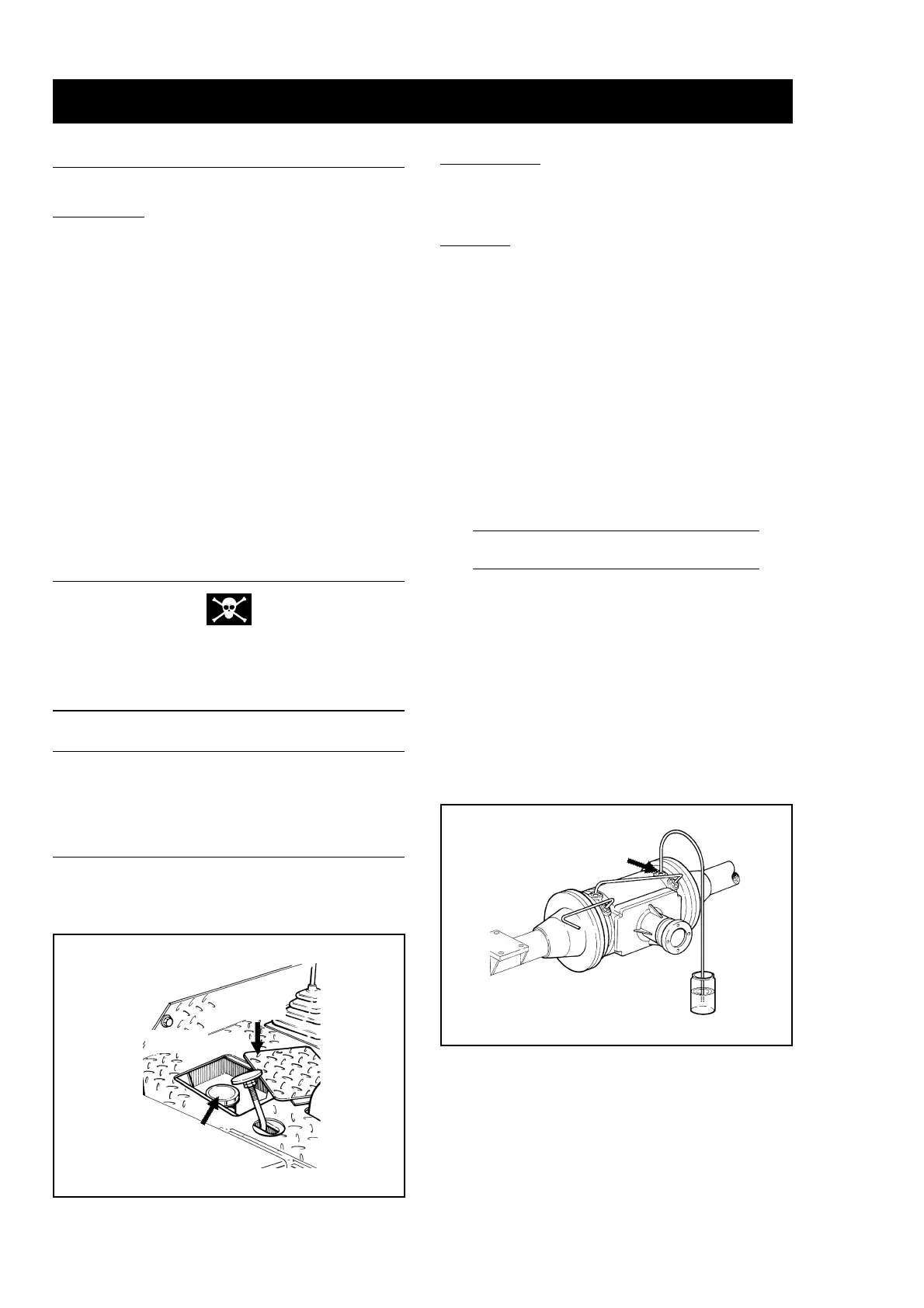

z Remove dust cap from bleeder plug of the slave cylinders.

z Attach a length of 8mm (5/16") internal diameter, clear P.V.C.

tubing to bleed valve. Place the other end of the tube into a

jar containing hydraulic oil ensuring that the end of the tube

is below the level of the oil.

z In the case of tandem master cylinders, always bleed the rear

axle brakes first.

z Slacken off bleed valve on the axle then proceed to pressurise

the system by pressing down the brake pedal repeatedly - as

far as it will go - until all air is expelled from the system.

Top Up the Fluid Reservoir as Bleeding Proceeds

z With brake pedal pressed down, tighten bleed valve, then release

the pedal. Remove tubing. Do not forget to replace dust cap.

z If the other axle has been serviced, repeat above sequence.

z Test system by applying maximum load to brake pedal for two

or three minutes to ensure that there are no leaks in the system.

z Check fluid level in reservoir.

z Road test the dumper. Re-check brake system for leaks or

damage.

Master

Cylinder

Floor

Plate

Removable

Cover

Bleed Plug

PVC

Tube

Loading...

Loading...