June 2004 9507EM/5

2-33

2 to 9 Tonne Dumper Instruction Manual

Maintenance

Clutch Replacment - Models 2 and 3 Tonne

Straight and Swing Skips

Before carrying out the following procedure it is advisable to

thoroughly clean the machine.

z Remove the gearbox, see Gearbox Section.

z Slacken the six setscrews around the clutch cover. Once the

setscrews have been loosened undo them in a diagonally

opposite sequence, two turns at a time until the clutch cover

is loose.

z Remove all the setscrews, the clutch cover and the clutch

plate.

z Check for oil leaks from the rear of the engine and from

inside the clutch bell housing. If there are leaks they must

be rectified before fitting a new clutch assembly.

ALL Worn Components MUST be Replaced

z It is advisable to renew the Clutch Plate, Cover and Release

Bearing when servicing clutch.

z Clean and check the engine flywheel fitted to the engine

crankshaft, and check the primary shaft spigot bearing for

wear - replace as necessary.

When replacing the spigot bearing, care must be taken to

use the correct size drift or damage to the bearing may occur

preventing the aligning tool from entering the bearing. The

outside bearing face must be level with the face of the mating

flywheel.

If problems, other than wear, have been experienced with

the clutch the engine flywheel should be checked for run out

using a dial gauge. The crankshaft endfloat should also be

checked using a dial gauge. These procedures are beyond

the scope of this manual and reference should be made to

the engine manufacturers workshop manual.

z Place a clutch alignment tool through the new clutch plate,

ensuring the plate is the correct way round - Flywheel Side

is stamped on the metal just below the clutch lining, and fit

the alignment tool into the spigot bearing.

z Clean the contact face of the new clutch cover with petrol to

remove all traces of grease.

z Place the clutch cover over the alignment tool and position

on the two dowels.

z Hold in position using six new setscrews and washers. Screw

in until resistance is felt.

z Tighten the setscrews in a diagonally opposite sequence, two

turns at a time until the setscrews are tight.

z Use a torque wrench to finally tighten the setscrews to 23.5

Nm. (17 lbs/ft.)

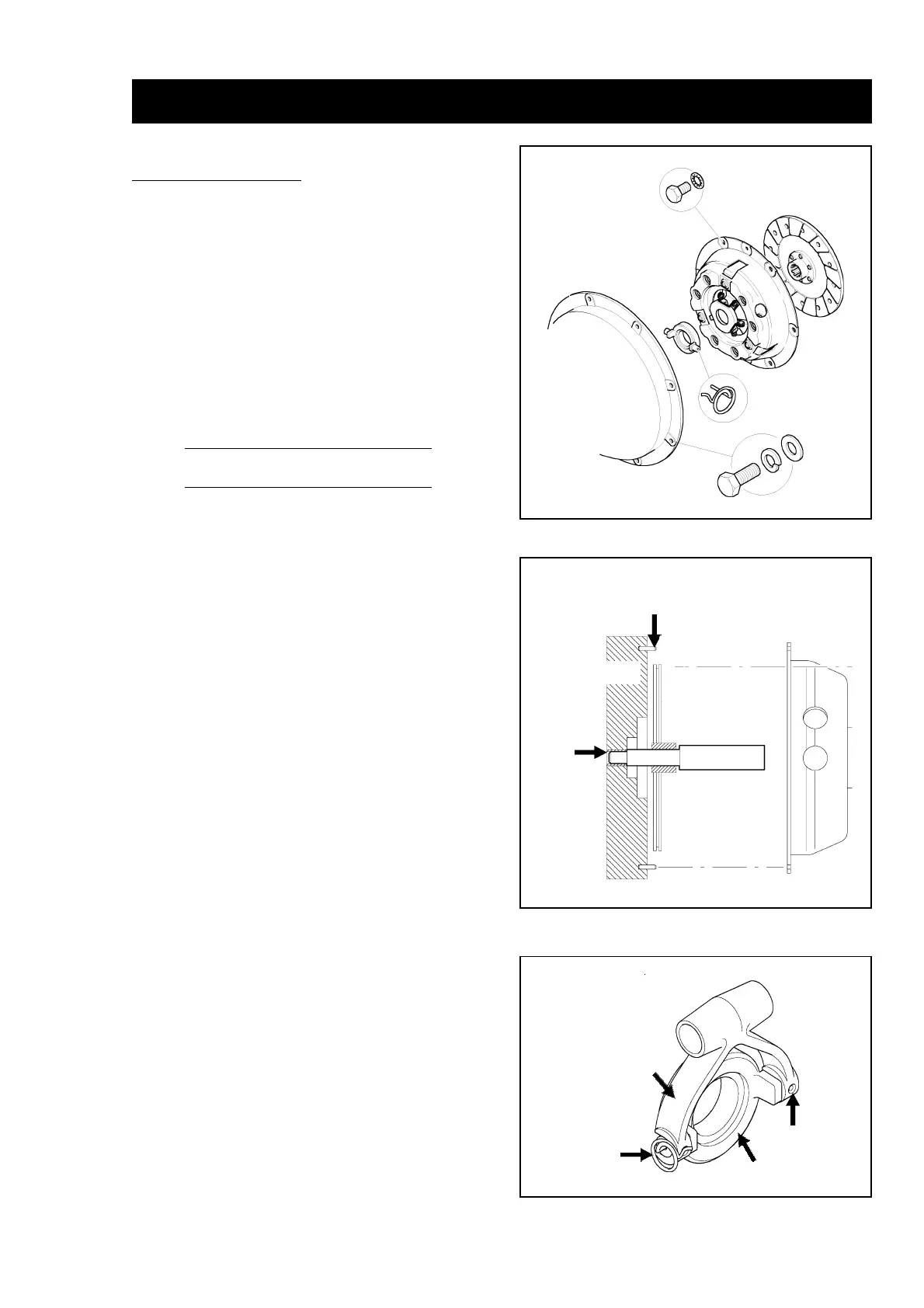

z Renew the release bearing, if necessary. Ensure the locking

spring is located correctly in the indent on the operating fork.

z Refit the gearbox, see Gearbox Section.

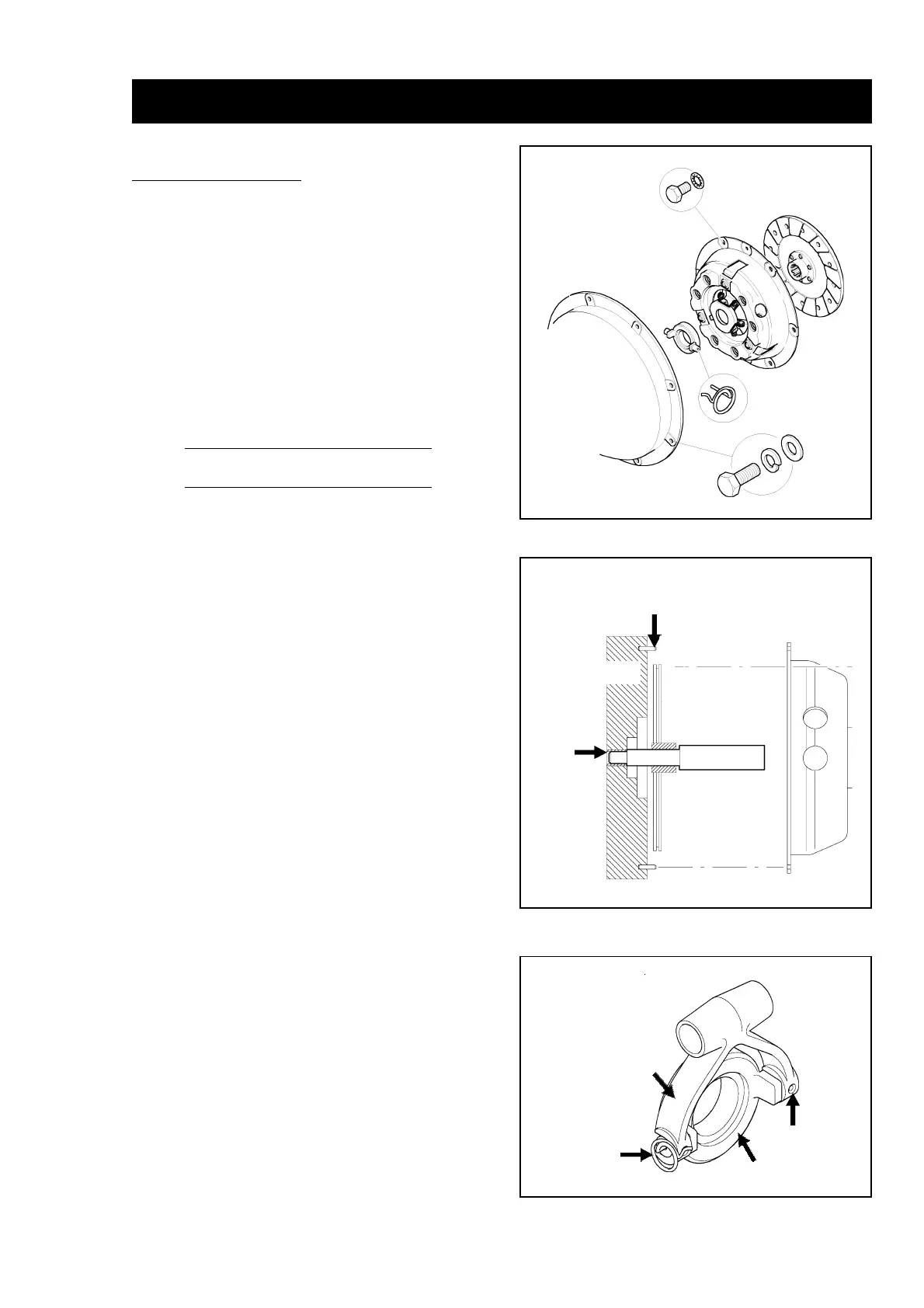

Gearbox

Release

Bearing

Clutch Cover

Clutch plate

Release

Bearing

Fixing Spring

Spigot

Bearing

Clutch Cover

Alignment Dowels

Clutch

Plate

Clutch Aligning

Tool

Engine Flywheel

Clutch

Cover

Fork

Release Bearing

Locking

Spring

Indent

Loading...

Loading...