11

CP.B24 CONTROL UNIT

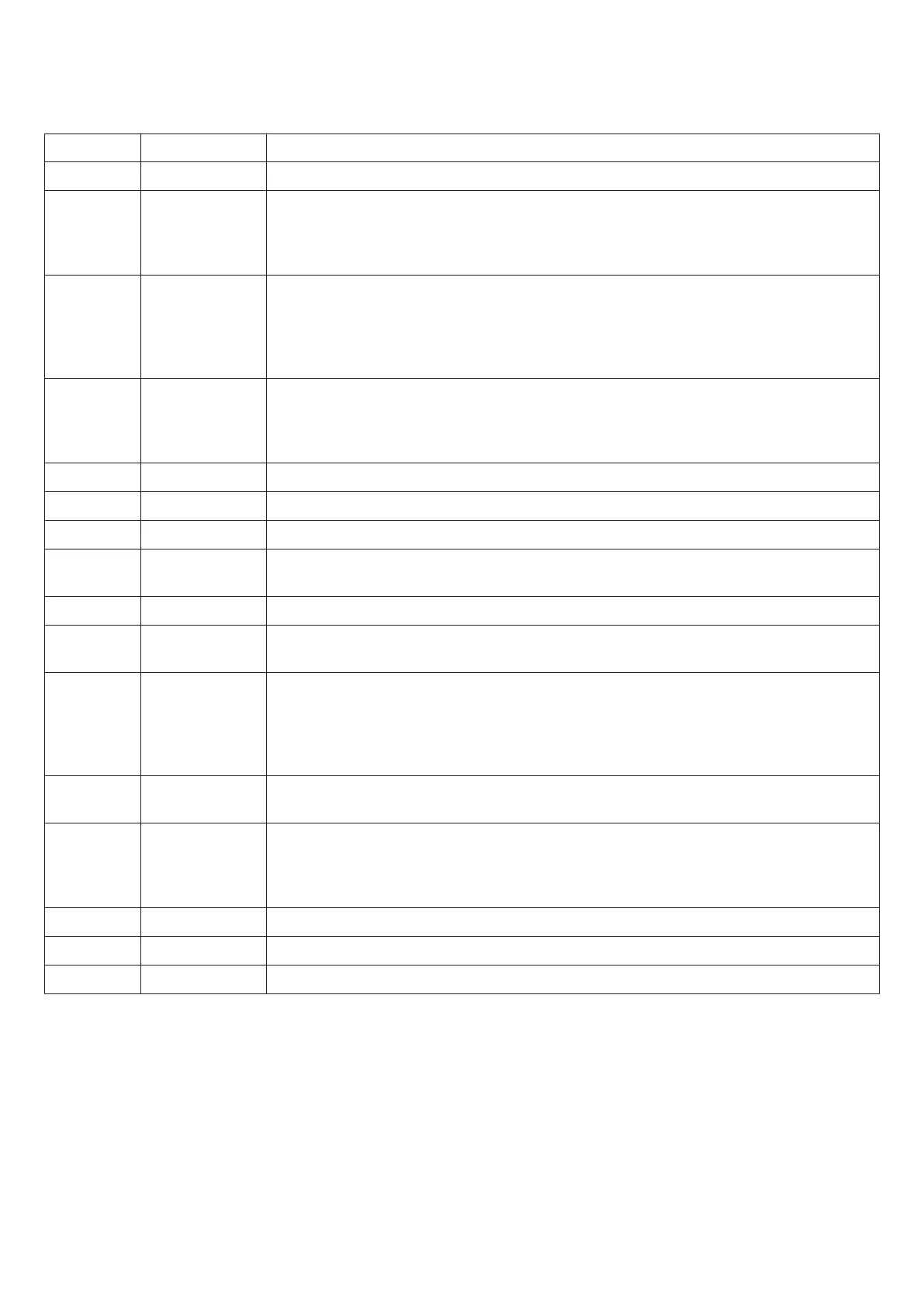

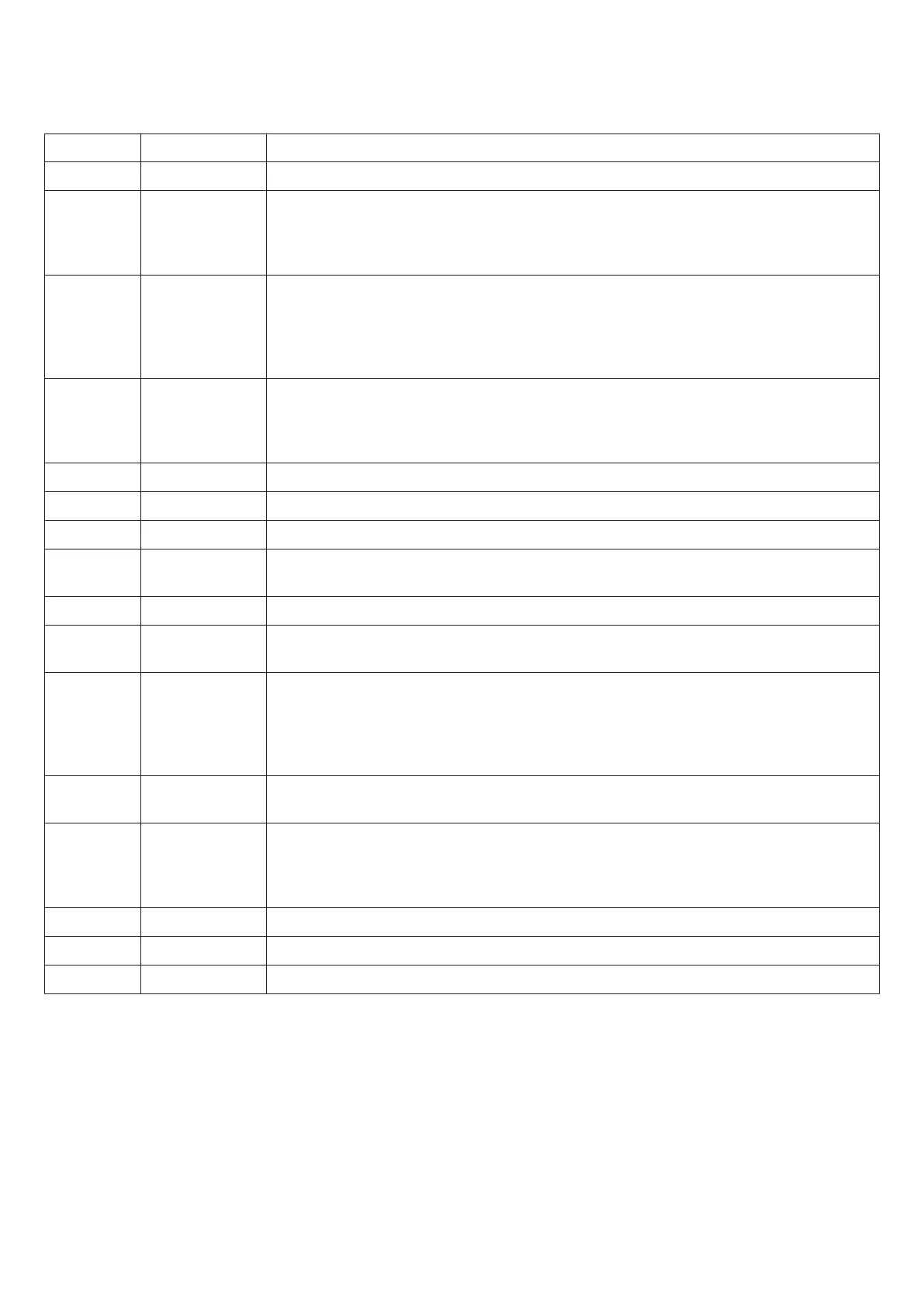

WIRE DIAGRAM

Wire connections shown in Fig. 1 are described hereunder:

Terminals Function Description

M+/M- Motor Quick connector for motor connection, 24VDC 120W max

COM

SWO

SWC

Limit switches

Quick connector for limit switch connection.

COM: Common to limit switches

SWO: Input, OPEN limit switches (N.C. contact)

SWC: Input, CLOSE limit switches (N.C. contact)

BAR/BAR SAFETY EDGE

Input, safety edge contact

Resistive edge: Closed “DAS” jumper

Mechanical edge: Open “DAS” jumper

If the safety edge is activated, the gate stops and the performs a movement reversion

for 3s

PED PEDESTRIAN

Input, pedestrian push-button (N.O. contact). It controls the partial opening of the gate

according to the value preset by TPED.

Active with completely closed gate.

It becomes “CLOSE” input with logics OPCL:ON or HTR:ON.

PHOTA Open Photocell Input, photocell activated in both opening and closing phases

PHOT Photocell Input, photocell activated in the closing phase only

STOP STOP Input, STP push-button (N.C. contact)

P.P. Step-by-Step

Input, step-by-step push button (N.O. contact)

It becomes “OPEN” input with logics OPCL:ON or HTR:ON.

+COM COMMON Common to all control inputs.

SHIELD/

ANT

Antenna

Antenna connection to the built-in receiver card

SHIELD: Shield/ ANT: Signal

FAST

24V

SLOW

0V

Secondary

Transformer

Inputs, connection of the secondary transformer

FAST: Input, 23V, it powers the motor during operation at normal speed

23V: power supply of accessories

SLOW: Input, 15V, it powers the motor during braking

0V: Input, 0V

IICH 2°Ch radio

Output, second radio channel of the built-in radio receiver.

N.O. contact, power-free.

+ 24V - 24 VAC/DC

Output, power supply of accessories, 24VAC/0.5A max.

CAUTION: in the event of installation of the battery loader card CB.24V, the output

(without mains power supply) will feature a voltage of 24VDC - polarised.

Check the correct connection of devices.

BLINK Flashing light Connection of the ashing light, 24VDC 15W max.

SCA SCA Open gate warning light 24Vac output.

ENCODER Encoder

Connector for the connection of the position sensor (encoder), integrated in the motor.

TO CHECK CONNECTIONS

Before programming the control unit, check that the motor is correctly connected:

1) Cut off power supply.

2) Manually release the gate leaf, move the same at approx. half stroke and block it again.

3) Power the system again.

4) Press key <-> to send a step-by-step control signal.

5) The door leaf should open. If not, use the logics MINV to reverse the rotation direction of the motor and the limit

switches (see Fig.3).

6) Carry out the self-learning of the stroke and trigger thresholds, as shown hereunder in the AUTO menu.

Loading...

Loading...