17

caldaie

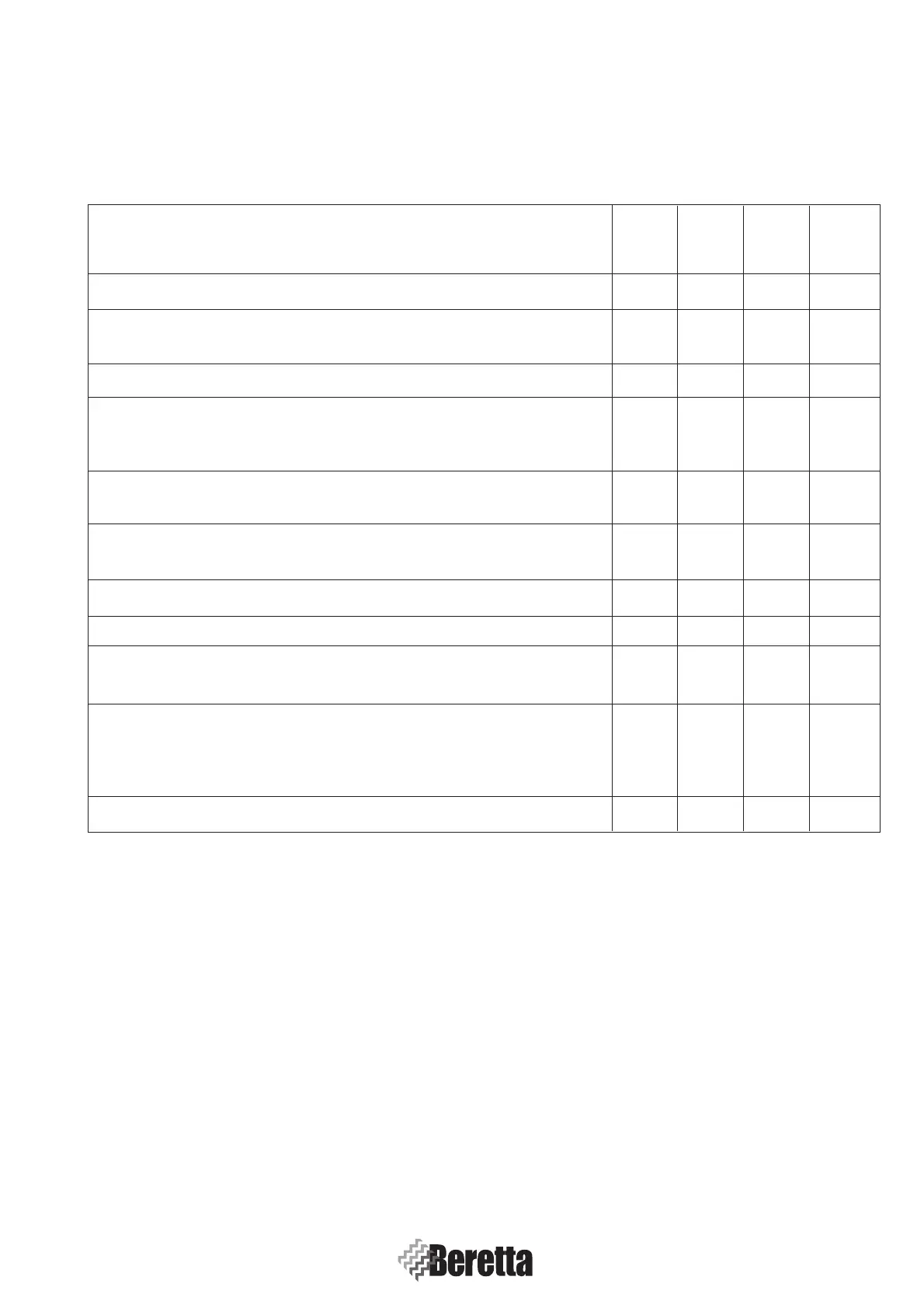

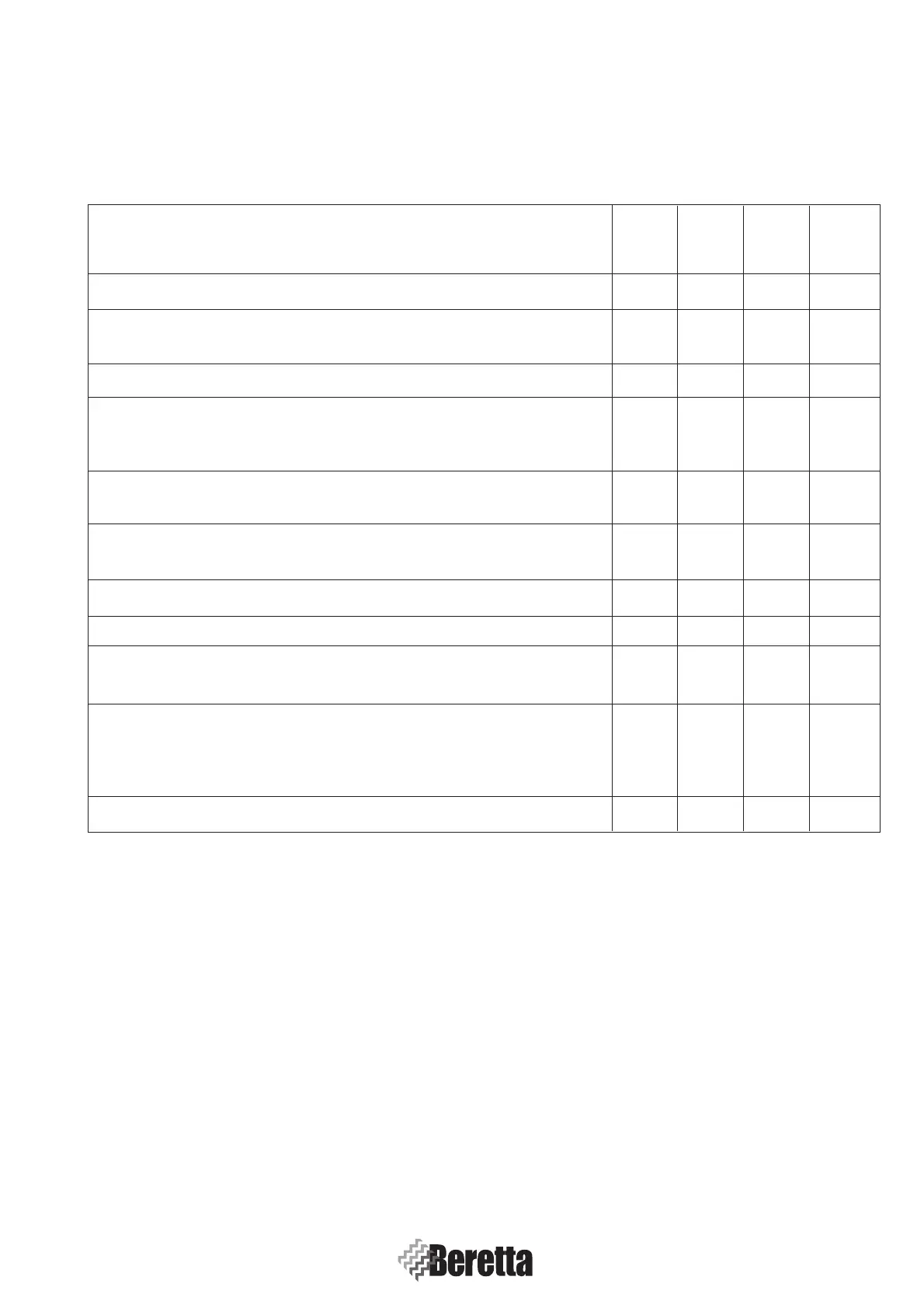

BURNER CLEANING AND NOZZLE CHECK

Table 4.4.14 page 37- 38

BI-THERMAL EXCHANGER CLEANING (CALCIUM REMOVING

WASHING, IF NECESSARY)

- Table 4.4.8 pages 28-30

FAN, VENTURI AND PITOT CLEANING - Table 4.4.19 page 44

DHW START-UP CHECK WITH MINIMUM CAPACITY

-

WORKING TESTS FOR BOILER ON SANITARY page 67

CALIBRATIONS AND ADJUSTMENTS CHECK - Sect. 2.4 page 13

CHECKS ON BLOCK SAFETY DEVICES, MODULATION, OPERATORS

CLOSING AFTER FLAME EXTINGUISHING

-

WORKING TESTS FOR BOILER ON HEATING pages 65-66

AND ON SANITARY page 67

X

X

X

EXPANSION TANK LOAD CHECK - Sect. 2.1 page 11

X

4 MAINTENANCE

4.1

REGULAR PROGRAMMED MAINTENANCE TABLE

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

4.2 TOOLING NEEDED FOR THE BOILER MAINTENANCE WORKS

- Magnetic PH1 screwdriver

- Magnetic PH2 screwdriver

- Broad tipped screwdriver

- 7mm socket wrench

- 5mm – 13mm – 23mm – 24mm – 30mm wrenches

- Scissors

- Molokite 111 type lubricant

- Cleaning rags

- Thermoconductive paste

- Thermoconductive paste

- Pliers

EXHAUST AND SUCTION DUCTS CHECK - TERMINALS

CHECK - Sect. 7.5 e 7.6 page 73

ELECTRODE CHECK AND CLEANING - Table 4.4.3 pages 22-23

CHECK ON FILTER - Table 4.4.4 page 24, CAPACITY LIMITING DEVICE -

Sect. 1.5.6 page 4, BY-PASS - Table 4.4.15 page 39, SEALS AND LOADING COCK

- Sect. 7.4 page 72

COMBUSTION ANALYSIS - Sect. 2.5 page 15

X

X

X

X

X

X

X

X

X

X

X

X

OPERATIONS TO BEPERFORMED AFTER THE:

1°

year

2°

year

3°

year

4°

year

Loading...

Loading...