4 Installation and Commissioning BigRep ONE

60

4.3. Commissioning and Connecting the Printer

Do not connect the device to its power supply before having aligned the frame

and print bed. & Chap. 4.4 Aligning / Leveling Bed and Frame

4.4. Aligning / Leveling Bed and Frame

The BigRep ONE must be aligned to ensure that the distance between the print

bed and the extruder is consistent.

Please note that there is a dierence between aligning the frame, aligning the

print bed (leveling) and adjusting the distance between nozzle and bed:

› The frame must be aligned/re-aligned mechanically before initial commis-

sioning and aer any transport. It will be done by BigRep service person-

nel during set-up.

› Bed leveling should be done aer transportation or if the leveling needs to

be improved. It can be done by the user with the BigRep User Interface.

› Adjusting the distance between nozzle and bed must be done by the user

aer replacing the extruder or hotend and aer any relocation of the print-

er.

Aligning the Frame and Gantry

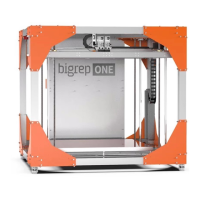

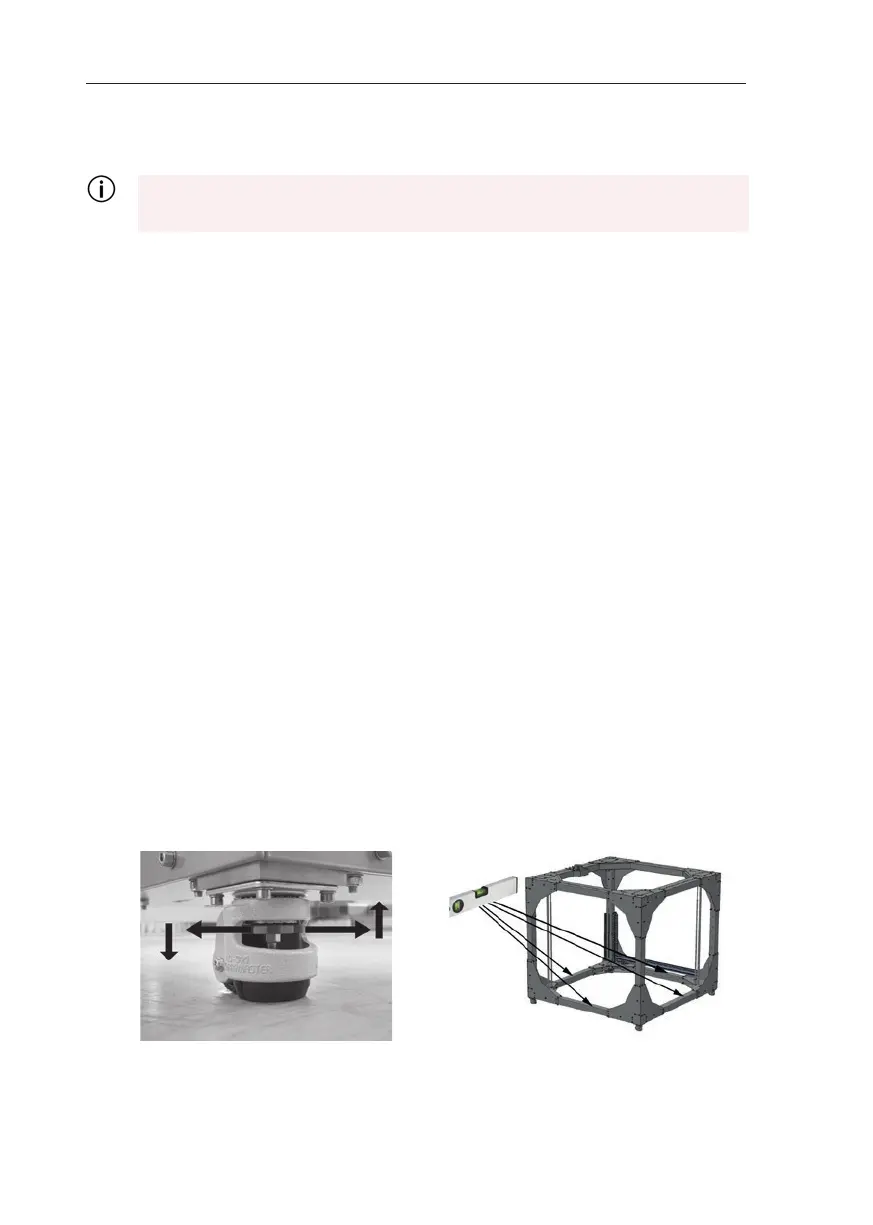

Before initial use and aer transport, the device must be leveled at the vertically

adjustable machine base (G) using a spirit level.

To change the height and for horizontal alignment, adjust the idler wheel at the

machine base as shown in (Fig. 4-2) and check the frame’s horizontal alignment

with a spirit level (Fig. 4-3)

Initial commissioning (service setup) of the BigRep ONE may only be per-

formed by personnel trained for this purpose by BigRep.

Fig. 4-3: Align the frame

Fig. 4-2: Idler wheel machine base

Loading...

Loading...