VAP 1 / VAP 2 06/2020 Page 25/52

5.2 Adjusting the gas ballast

When condensable vapors are aspirated, they can be compressed and condensed

via the saturation

pressure. The gas ballast valve can be opened by turning the

adjustment cap (A), whereby ambient air is sucked in. Air flows into the suction

chamber in the suction line, prevents condensation and flushes out the pump. The

operation leads to an increase in the final pressure and the operating temperature.

(A)

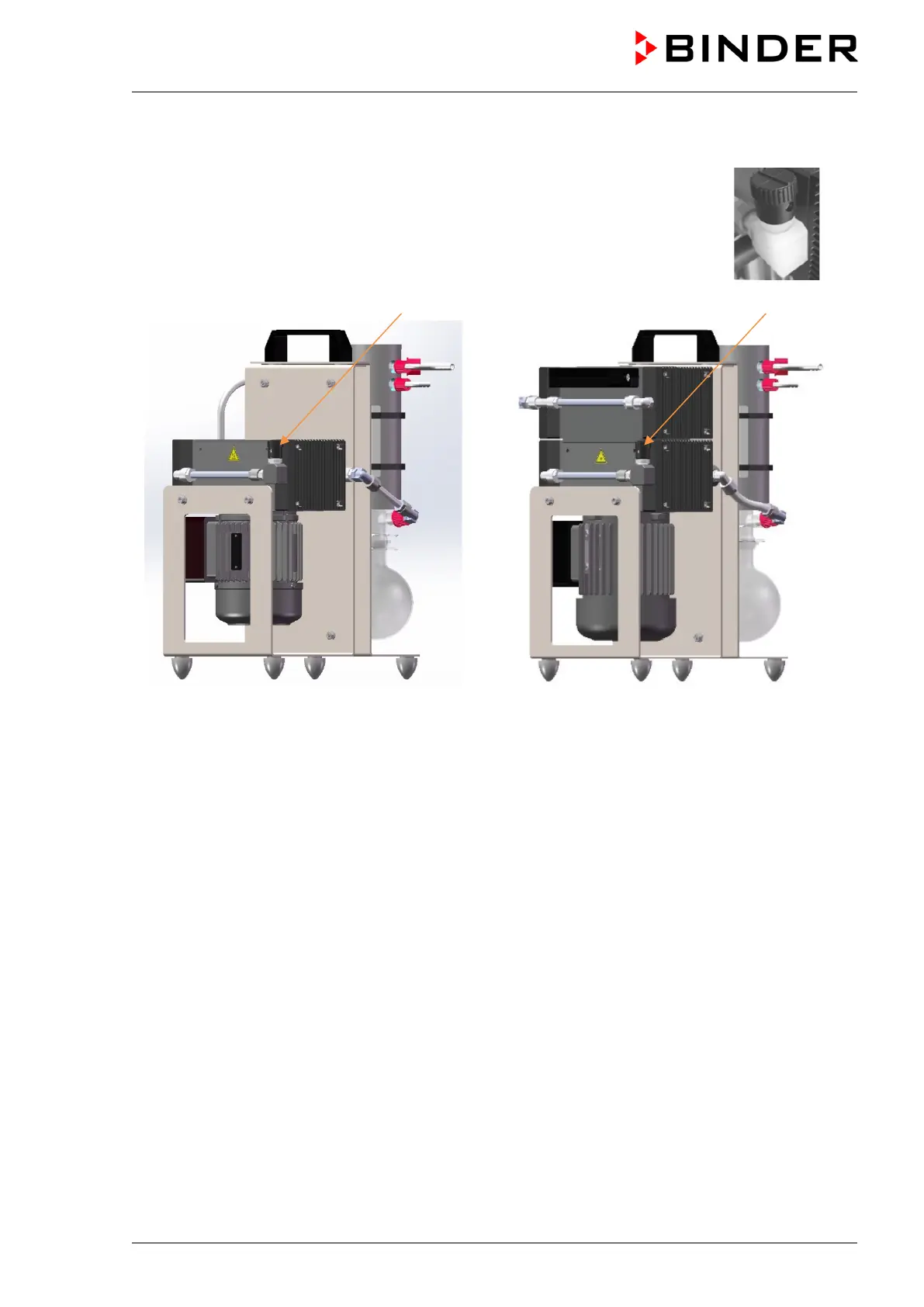

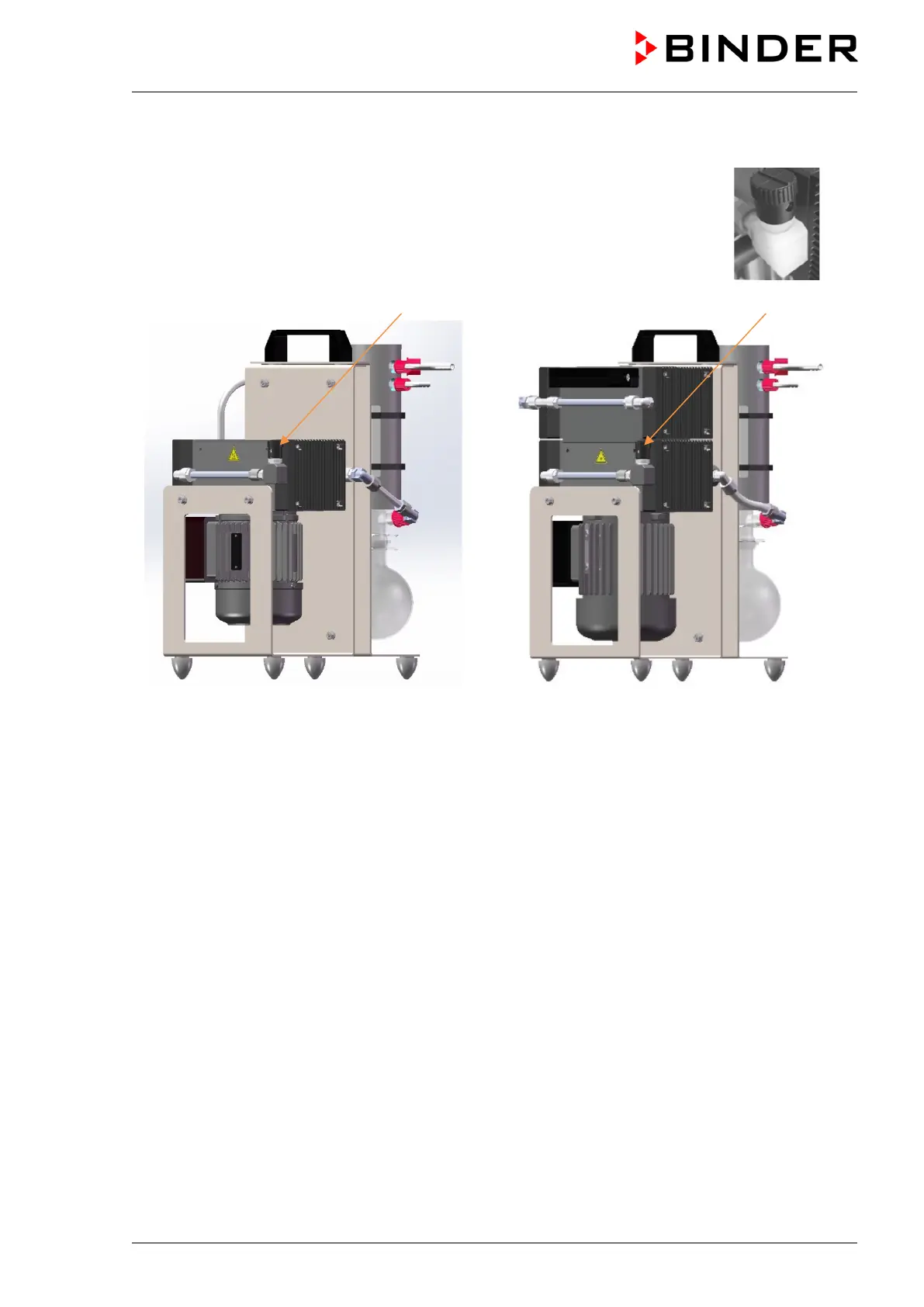

Figure 10: Rear view of VAP 1 / VAP 2 vacuum pump with position of the gas ballast valve

(A) Gas ballast valve with black adjustment cap

6. Operation

When operating with the VD vacuum drying oven the vacuum pump runs in continuous operation. The

pumps are delivered with operating mode S1 (continuous operation with constant load).

The VD vacuum drying oven controls the connected pump and thus reaches the vacuum set at the VD.

6.1 Daily inspection

• Check the vacuum pump daily for unusual running noise and heat development on the pump surface.

• Check the electrical and vacuum connections every day.

• Check the filling level of the condensate catchpot every day and empty it as soon as necessary.

Loading...

Loading...