KT-210-424

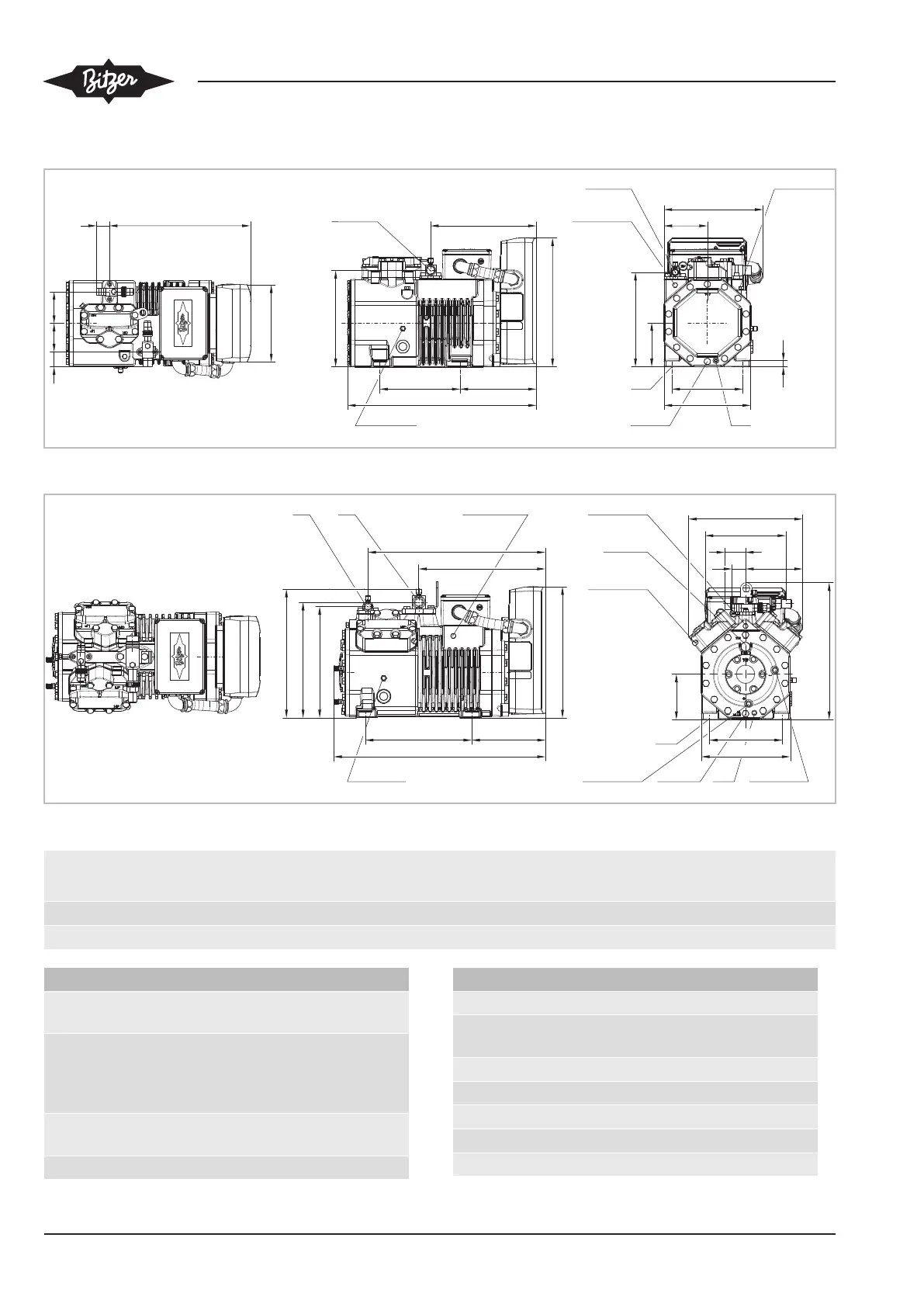

3.3 Dimensional drawings

1/8-27 NPTF

1 ( )HP

90

81

42

3 ( )LP

1/8-27 NPTF

M10x1,5

6

10

Ø12

5 / 8

7/16-20 UNF

SL

DL

241

198

Ø13

123

263

276

121

294

212223

525

401

37

358

269

Ø16 (5/8 )''

Ø22 (7/8 )''

18

221

Fig.3: 2DES-3.F1Y

241

125

310

155

K

G

198

7/16-20 UNF

5 / 8

SL

DL

202293

582

488

348

Ø12

M10x1,5

10

L

H

361

1 ( )HP3 ( )LP

1/8-27 NPTF1/8-27 NPTF

Ø13

2 ( )HP

1/8-27 NPTF

12611

7/16-20 UNF

7/16-20 UNF

16

M20x1,5

374

221

M

Fig.4: 4FE-5.F1Y, 4EE-6.F1Y, 4DE-5.F1Y, 4CE-6.F1Y

G

mm

H

mm

K

mm

L

mm

M

mm

DL SL

4FE-5.F1Y, 4EE-6.F1Y 56 317 37 306 354 Ø16 (5/8'') Ø28 (1 1/8'')

4DE-5.F1Y, 4CE-6.F1Y 64 325 42 310 368 Ø22 (7/8'') Ø35 (1 3/8'')

Connection points

1 High pressure connection (HP)

Connection for high pressure switch (HP)

2 Connection for discharge gas temperature

sensor (HP)

(4VE(S)-6Y .. 4NE(S)-20(Y): connection for

RI/CIC sensor as an alternative)

3 Low pressure connection (LP)

Connection for low pressure switch (LP)

4 CIC system: Injection nozzle (LP)

Connection points

4b Connection for RI/CIC sensor

4c Connection for RI/CIC sensor (MP / opera-

tion with refrigerant subcooler)

5 Oil fill plug

6 Oil drain

7 Oil filter (magnetic screw)

8 Oil return (oil separator)

8* Oil return for NH

3

with insoluble oil

Loading...

Loading...