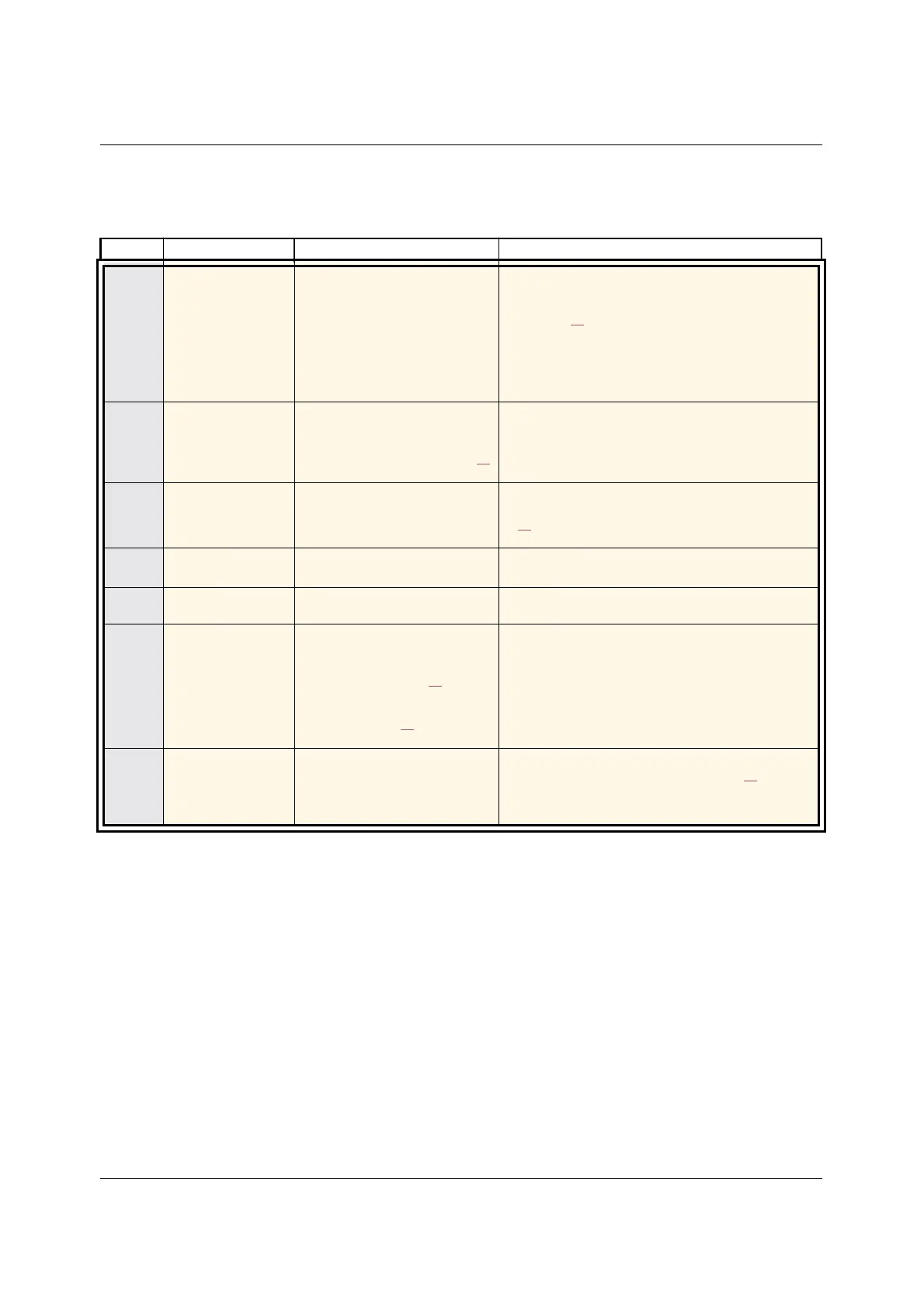

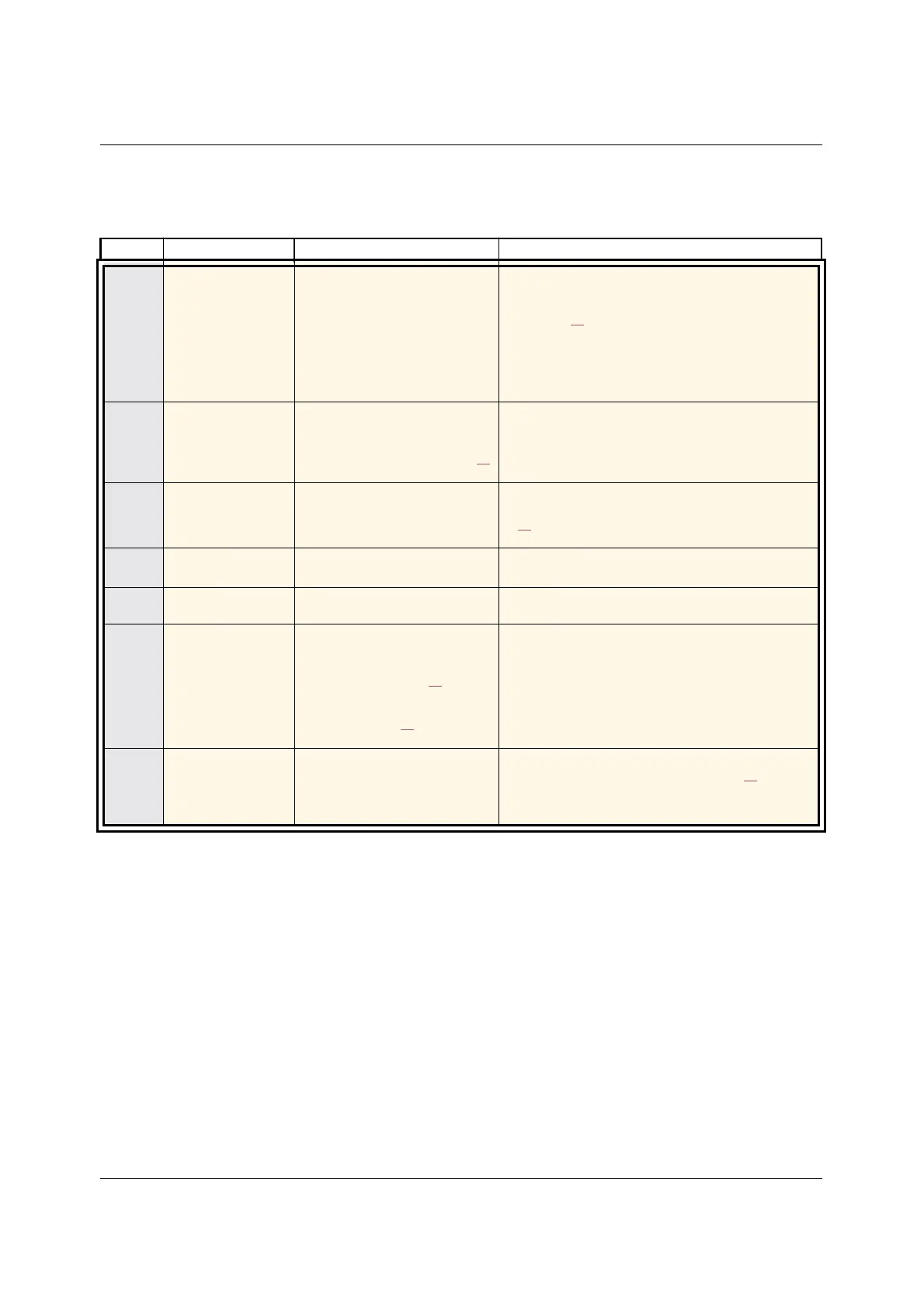

90

Diagnostics and Troubleshooting

Fault detection codes that can be reset with the automatic restart function, after the

cause has disappeared (continued)

Code Name Possible causes Remedy

PHF Input phase loss • Drive incorrectly supplied or a fuse

blown

• Failure of one phase

• 3-phase ER12 used on a single-

phase line supply

• Unbalanced load

• This protection only operates with

the drive on load

• Check the power connection and the fuses.

• Use a 3-phase line supply.

• Disable the fault by setting Input Phase loss detection

IPL page 80

= nO.

SCF5 Load short circuit • Short-circuit at drive output

• Short circuit detection at the run

order or DC injection order if

parameter IGBT test Strt page 81

is set to YES

• Check the cables connecting the drive to the motor, and

the motor’s insulation

SLF1 Modbus

communication

• Interruption in communication on

the Modbus network

• Check the connections of communication bus.

• Check the time-out (Modbus time out ttO parameter page

83

)

• Refer to the Modbus user manual

SLF2 Software

communication

• Fault communicating with

Software

• Check the Software connecting cable.

• Check the time-out

SLF3 HMI communication • Fault communicating with the

external display terminal

• Check the terminal connection

ULF Process underload

fault

• Process underload

• Motor current below the

Application Underload threshold

LUL parameter page 53

during a

period set by Application

underload time delay ULt

parameter page 53

to protect the

application.

• Check the process and the parameters of the drive to be

in phase

tJF IGBT overheat • Drive overheated

• IGBT internal temperature is too

high according to ambient

temperature and load

• Check the size of the load/motor/drive.

• Reduce the Switching frequency SFr page 57

.

• Wait for the drive to cool before restarting

Loading...

Loading...