3. The lift

9

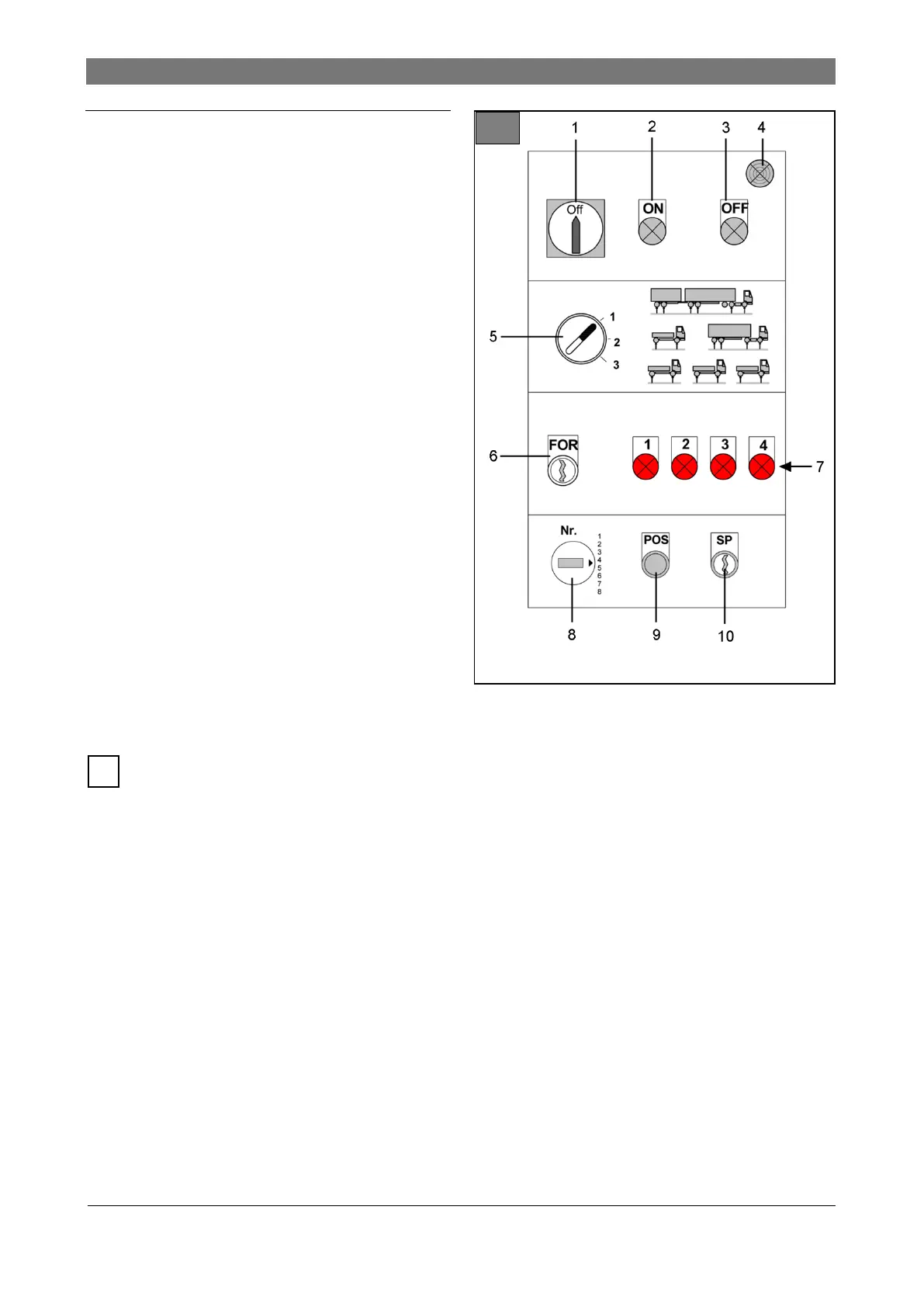

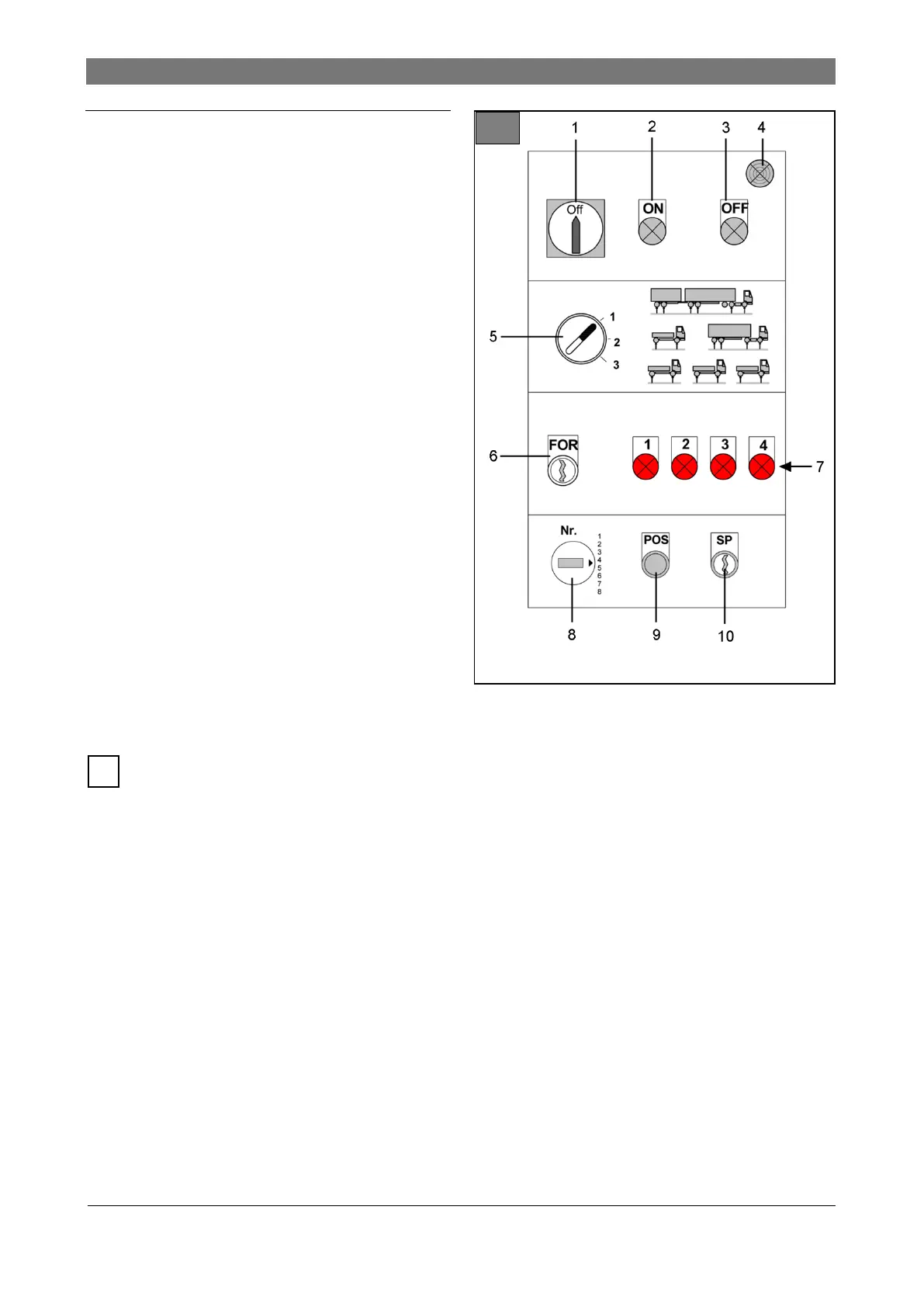

3.4 Control cabinet

Illustration 11: Controls on control cabinet

1 Main switch, emergency stop

2 Controls On

Turns the main contactor on. The control panels

are now activated.

3 Controls Off

Turns the main contactor off. The control panels

are now deactivated.

4 Buzzer

Acoustic alarm during lowering the lift below 500

mm (foot protection).

5 Lift allocation switch (optional)

Lifts with 4, 5 or 6 lifting cylinders can be divided

into individual workplaces.

● A control panel is available for each work-

place.

● The individual control panels are activated

corresponding to the lift allocation.

6 FOR key switch

Manual adjustment of the vehicle position.

● Automatic controls are deactivated.

● Current lift allocation is canceled.

● Control panel 1 is activated.

● Control commands Up and Down apply

to activated lifting cylinder.

For safety reasons, a second operator must

be called in. This person must permanently

activate FOR switch and monitor the operator.

7 Fault report indicators L1 ... L4

15 fault reports are allocated to the 4 indicators,

depending on On/Off combination ( chapter

7).

Distance between axles preset “AAV”, optional

( chapter 5.14).

8 Rotary switch for 9 memory presets

The necessary lifting cylinder positions for fre-

quently used vehicles can be stored.

9 POS button

The lifting cylinders move to the selected posi-

tion.

10 SP key switch

The current lifting cylinder position is pro-

grammed for the set memory preset (position

number).

Loading...

Loading...