8. Maintenance

23

3. Measure vehicle height again and note the drop

travel on each axle.

4. Check working cylinders: Press and hold button

“2” (Illustration 22) approx. 1 min.

All solenoid valves of the safety cylinders are

opened. The working cylinders carry the entire

load.

Initially the load drops a little (maximum

100mm). Afterwards it must come to a

stop with activated button.

5. Measure vehicle height again and note the drop

travel on each axle.

8.13 Calibrate sensor setting

1. Lower all lifting cylinders to lowest position.

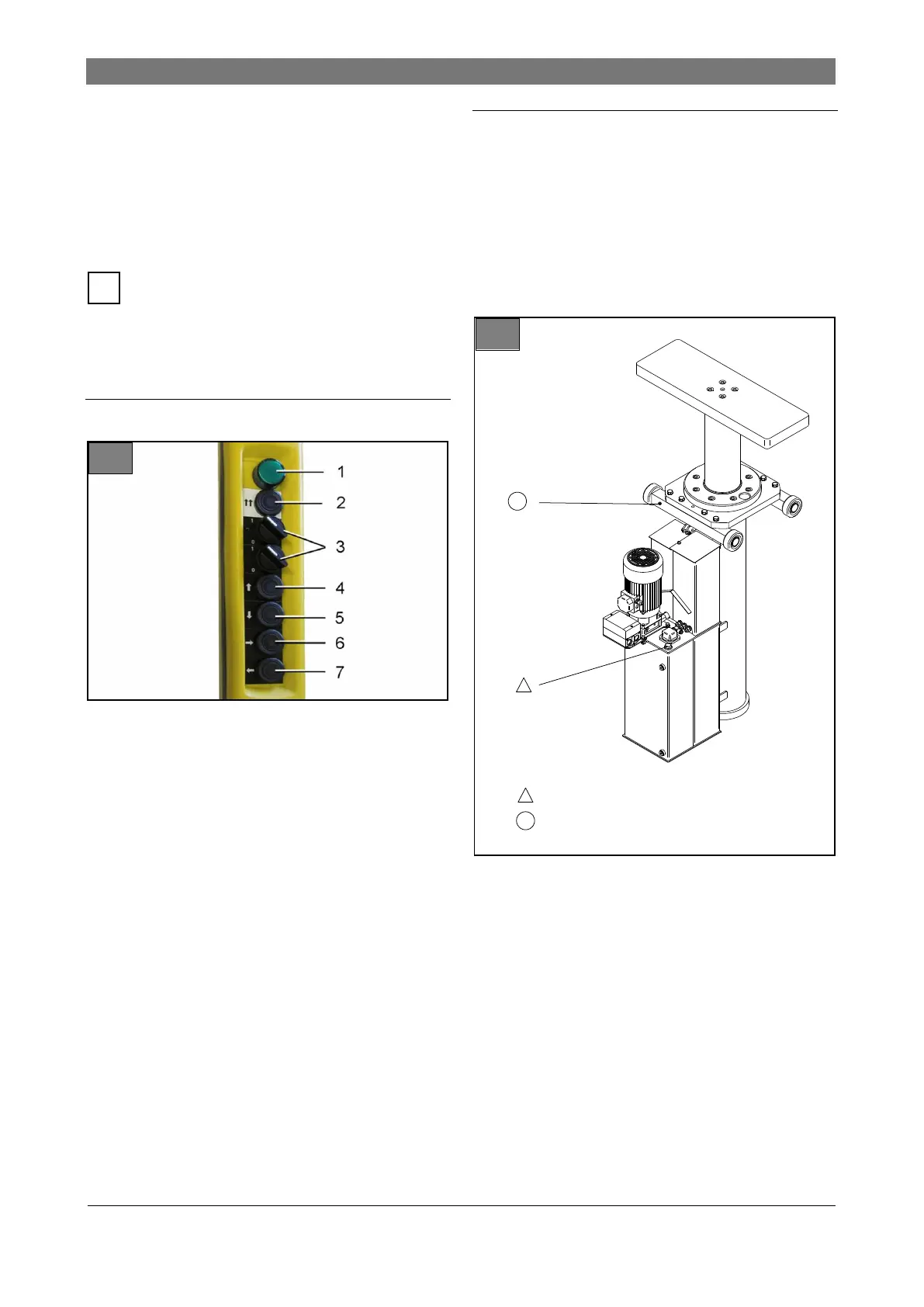

2. Set all lifting cylinder activating switches (3) to

zero.

3. Press and hold Synchronous operation (2) and

Back (7) buttons for approx. 10 seconds.

4. Press and hold Up (4) and Forward (6) buttons

for approx. 10 seconds.

5. Press and hold Down (5) and Back (7) buttons

for approx. 10 seconds.

The sensors are now calibrated.

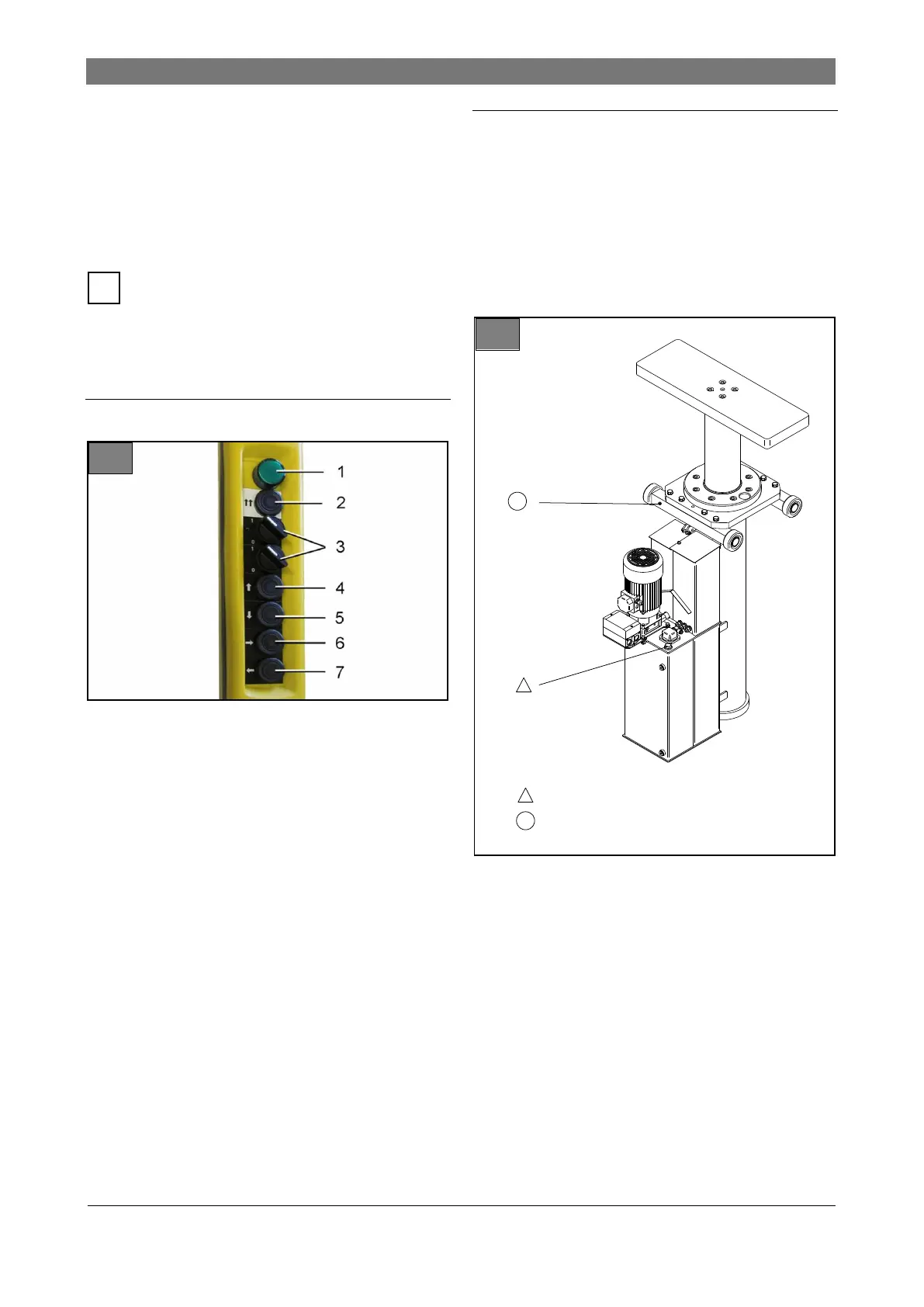

8.14 Change hydraulic oil

Always change the hydraulic oil for all lifting cyl-

inders.

Permitted hydraulic oil:

Hydraulic oil with viscosity 22 cST/40° and quality

HLP DIN51524 T2.

Required amount of oil:

65 l per lifting cylinder.

1. Lower all lifting cylinders completely, switch off

and secure lift.

2. Open maintenance door and cover.

3. Remove dipstick.

4. Extract waste oil.

5. Fill fresh hydraulic oil up to the specified mark-

ing.

6. Replace dipstick.

7. Bleed lifting cylinder.

8. Check oil level.

9. Dispose of waste oil professionally according to

chapter 15.

Oil level / oil change

Lucrication

Loading...

Loading...