7. Malfunction reports

18

7. Malfunction reports

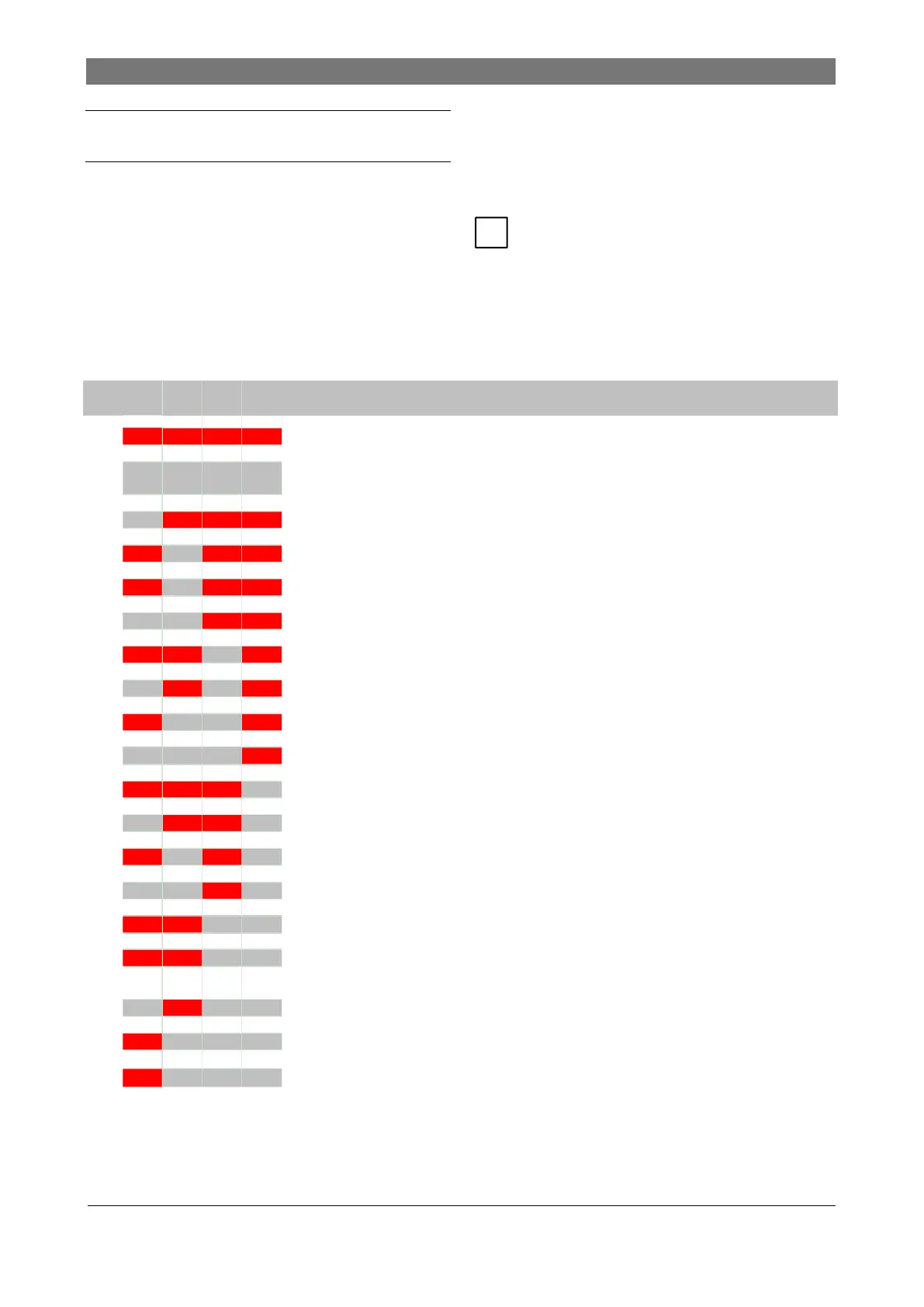

7.1 Malfunction indicator lamps

Malfunctions are indicated by means of 4 mal-

function indicator lamps L1 to L4 on the control

cabinet.

Operating functions on the respective control

panel are locked until the malfunction is rectified.

Acknowledge malfunction rectification after repair as

follows:

1. Turn off the equipment with the main switch.

2. Turn the equipment back on afterwards.

Contact the authorized customer service if the

malfunction is not rectified after the specified

corrective actions.

Malfunction indicator V2.17 02/2011

Lamp test after switching on, approx. 5 seconds.

Emergency stop or equipment switched off. On board 4 LEDs light up

red.

Motor overload switch has been triggered.

Malfunction on electronics board: ADC, voltage or CAN bus error.

FLASHES: Calibration error (sensors) or flash memory error.

Power output too hot or short circuit.

Cable break for level sensor.

Defective level sensor in oil tank.

Defective travel sensor AAV.

Defective push button (Up, Down, Forward or Back).

No lift change after movement command (speed = 0).

Direction monitoring lifting / lowering.

Positioning error (no target values stored).

FLASHES: Error AAV, movement locked

(e.g. lift > 300, cylinder loaded).

Synchronous run error: Maximum control difference exceeded.

FLASHES: Change in lift allocation not possible under load.

Loading...

Loading...