6. Malfunctions

17

6.1 Emergency lowering

Vehicle emergency lowering only to be carried

out by competent persons.

Danger to life due to electric shock

while working on open control cab-

inet.

Only electricians are permitted to work on the

open control cabinet.

Never touch live components.

Emergency lowering during power failure

1. Wait for the end of the power failure, if possible.

2. Then lower the vehicle in normal operation.

If there is no power supply, the vehicle can be

lowered by connecting a 24 V external power

supply.

1. Connect external power supply 24VDC, 6A ac-

cording to circuit diagram on control cabinet

(e.g. truck or forklift battery).

2. Switch on lift.

3. Switch on synchronized operation.

4. Lower the vehicle slowly as described in chapter

5.13 “Operation without controls”.

5. Remove external power supply.

6. Have malfunction repaired by electrician.

Lift secured during malfunction. Condition

cannot be acknowledged.

1. Check according to malfunction list in chapter 7

if “FOR” mode is permissible.

2. If permitted, lower the vehicle slowly as de-

scribed in chapter 5.13 “Operation without con-

trols”.

3. Clear malfunction. Contact authorized customer

service, if necessary.

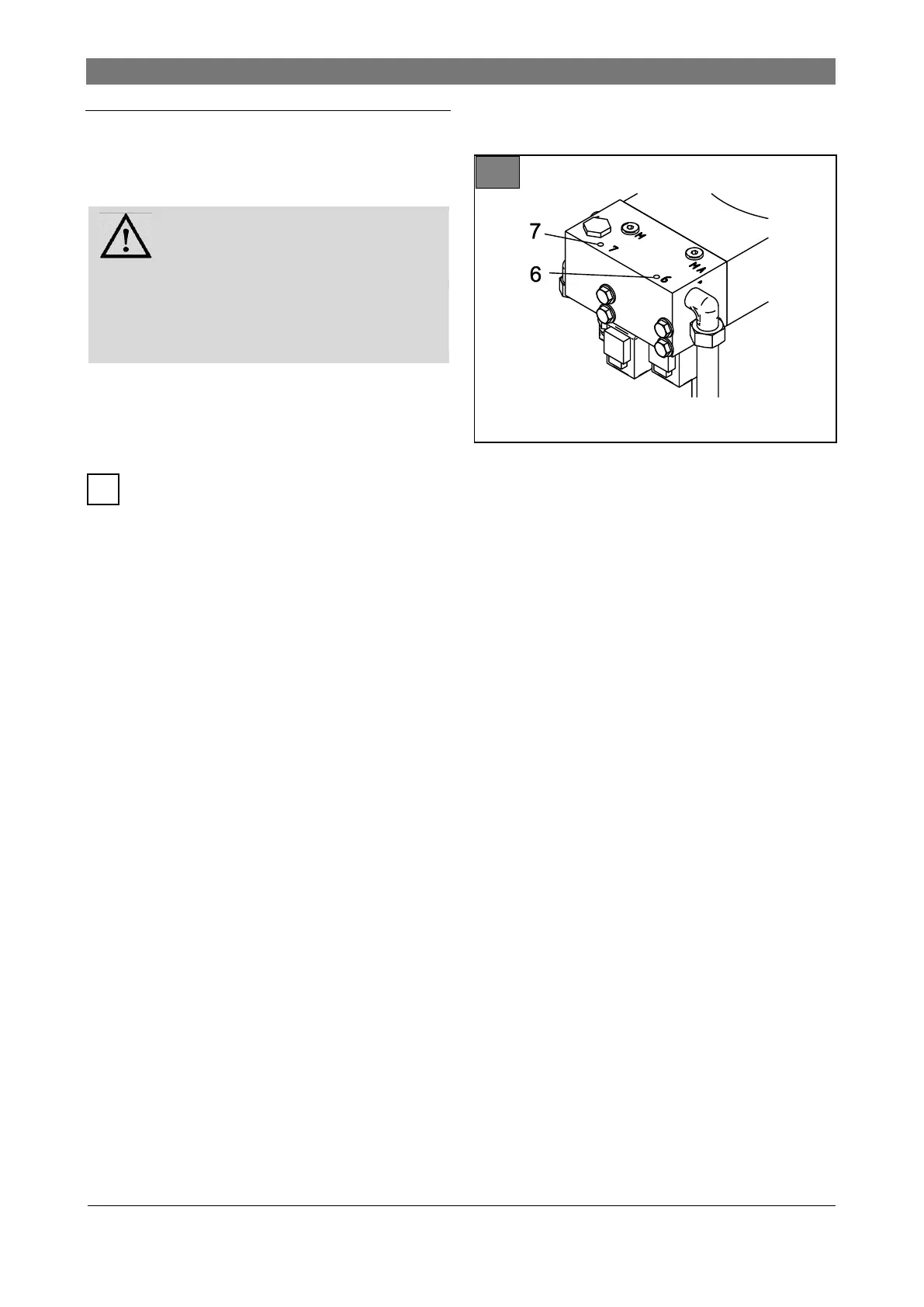

Lowering with FOR with defective solenoid

valve

1. Correct horizontal vehicle position with lifting

button ( chapter 5.13, Operation without

controls).

2. Open the maintenance door on the defective

lifting cylinders to have free access to hydraulic

components.

3. Loosen locking screw (6) approx. 2 turns. The

load does not lower.

4. Exit danger area under the vehicle.

5. Lower the vehicle slowly as described in chapter

5.13 “Operation without controls”.

6. Drive vehicle from the lift.

7. Close locking screw (6) again.

8. Attach protective cover and close maintenance

door.

9. Have malfunction repaired by electrician.

Loading...

Loading...