20 / 52

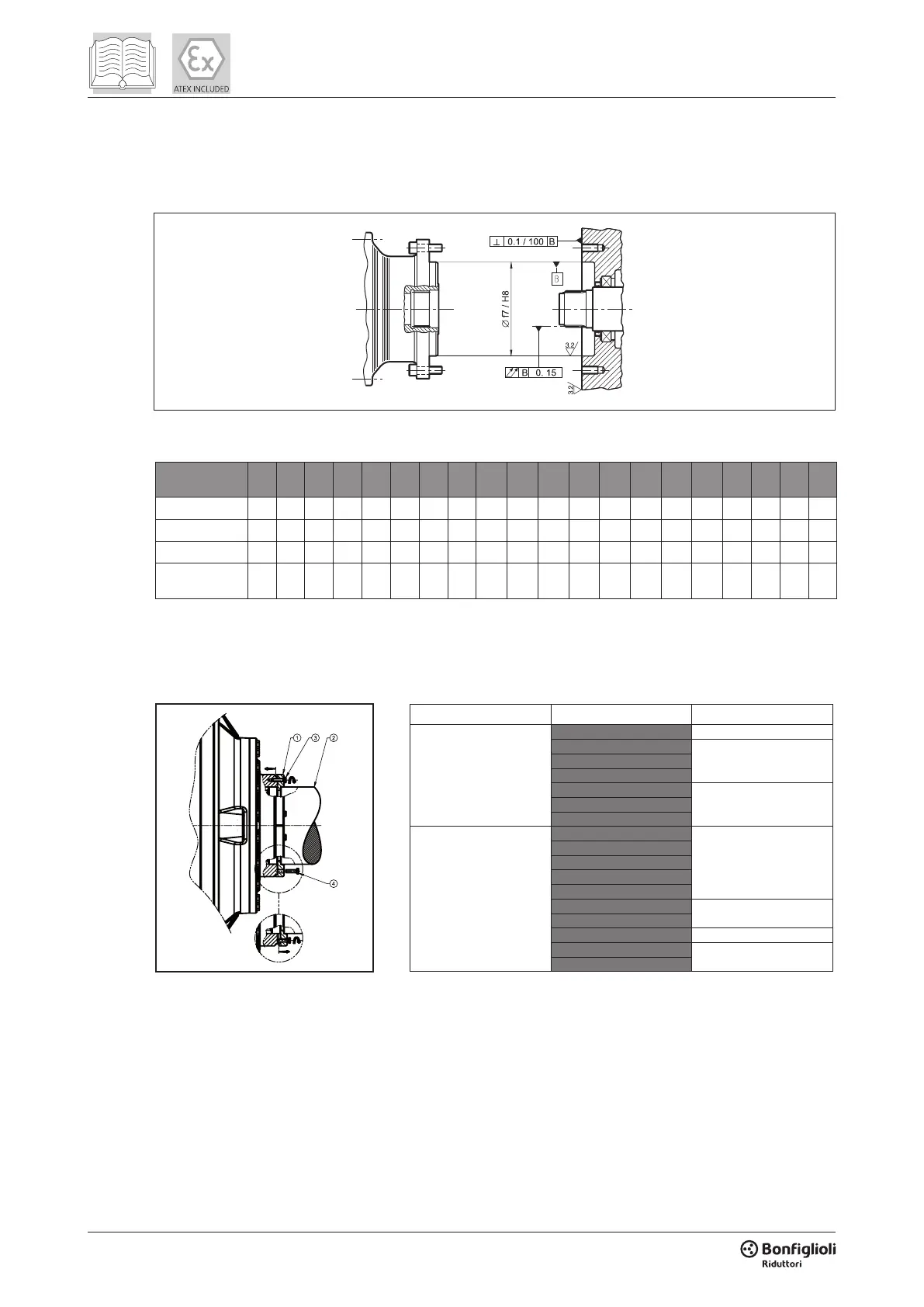

Mounting with hollow splined shaft

Ensure that the gear unit and driven shaft are aligned and that the latter is not subject to exing

during operation. See diagram below:

Flanged gear unit mounting bolts

For applications in areas that do not permit/allow this class, please contact the Technical Service

of the Manufacturer.

300...325

310M...318M

300 301 303 304 305 306 307 309

310M

311M

313M

314M

315M

316M

317M

318M

319 321 323 325

M10 M10 M12 M12 M12 M14 M16 M16 M16 M16 M16 M20 M20 M20 M30 M27 M30 M30 M42 M42

8 8 10 10 10 12 10 12 15 24 30 20 20 30 24 32 30 36 36 36

12.9 12.9 12.9 12.9 12.9 12.9 12.9 12.9 12.9 12.9 12.9 12.9 12.9 12.9 12.9 12.9 12.9 12.9 12.9 12.9

85 85 145 145 145 230 350 350 350 350 350 690 690 690 2350 1750 1750 1750 6750 6750

Bolt

Quantity

Class

Tightening

torque [Nm]

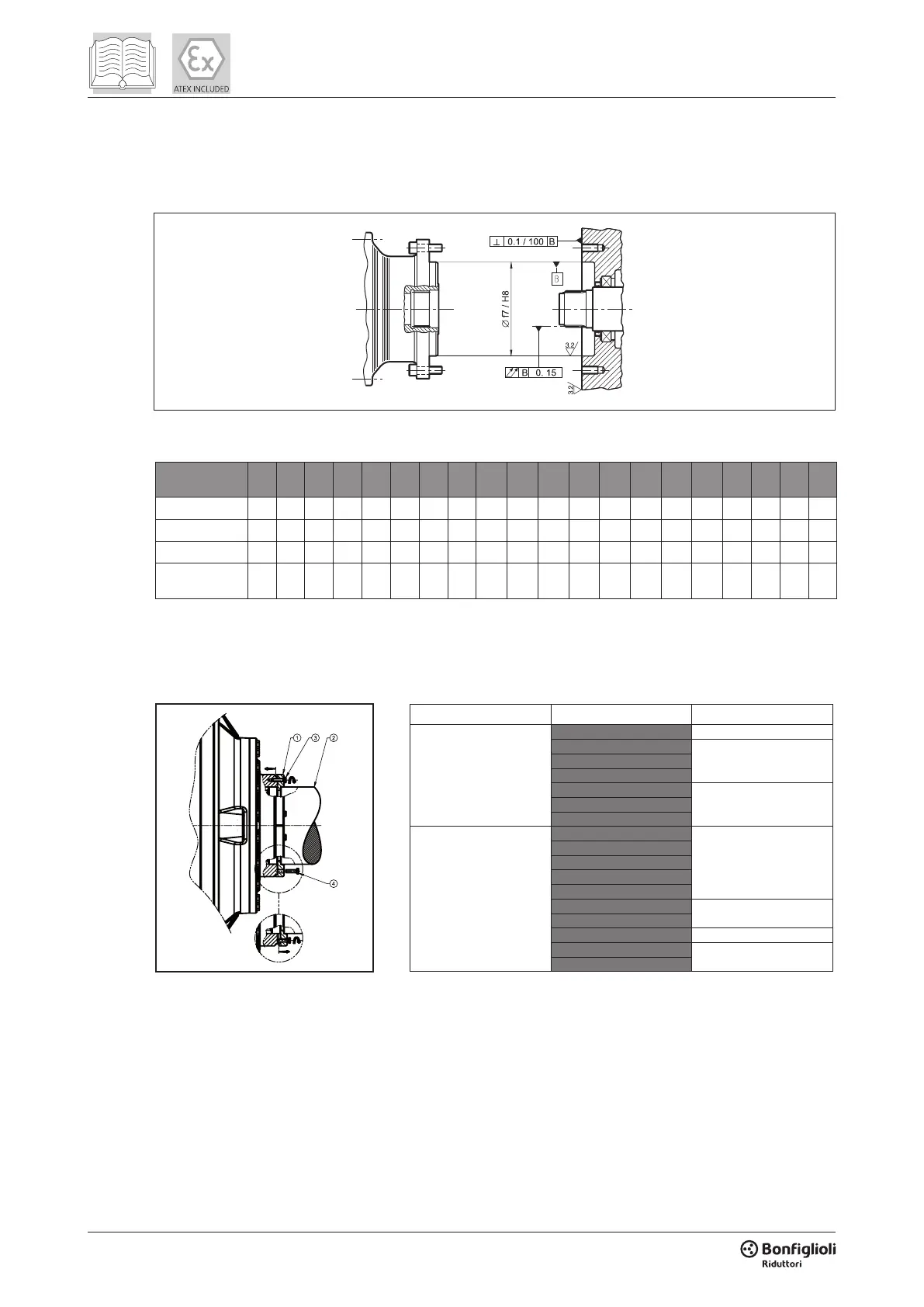

Customer’s shaft axial mounting version FDK (300-310 , 310M) and FZP (311-325 , 311M-318M)

• Remove the two axial mounting half-rings (1) from the gear unit

• Make the customer shaft (2) as indicated in the technical catalogue (see www.bonglioli.com for

up-to-date version)

• Properly lubricate both the shaft and its housing, then connect the shaft to the gear unit

• Apply the two axial mounting half-rings, by placing them in the respective circumferential housing

on the shaft

• Assemble the xing screws (3) by screwing them gradually and diametrically, applying the tight-

ening torque indicated in the “Dimensions” section of the technical catalogue (see www.bonglioli.

com for up-to-date version)

• To remove the shaft, loosen all the screws. Procure additional 4 screws (as shown in the table,

not provided with the gear unit) and screw them in the threaded holes on the two half-rings, react

on the gear unit up to the release of the shaft.

FDK

300 M4

301

M6303 / 304 / 305

306

307

M8309

310 / 310M

FZP

311 / 311M

M8

313 / 313M

314 / 315 / 314M / 315M

316 / 316M

317 / 317M

318 / 318M

M10

319

321 M12

323

M20

VERSION SIZE BOLTS x4

300 301 303 304 305 306 307 309

310

310M

311

311M

313

313M

314

314M

315

315M

316

316M

317

317M

318

318M

319 321 323 325

M10 M10 M12 M12 M12 M14 M16 M16 M16 M16 M16 M20 M20 M20 M30 M27 M30 M30 M42 M42

8 8 10 10 10 12 10 12 15 24 30 20 20 30 24 32 30 36 36 36

12.9 12.9 12.9 12.9 12.9 12.9 12.9 12.9 12.9 12.9 12.9 12.9 12.9 12.9 12.9 12.9 12.9 12.9 12.9 12.9

85 85 145 145 145 230 350 350 350 350 350 690 690 690 2350 1750 1750 1750 6750 6750

Bolt

Quantity

Class

Tightening

torque [Nm]

Loading...

Loading...