1 689 979 792 2010-02-24| Robert Bosch GmbH

Operation | BAT 121 | 17BAT 121 | 17 | 17 en

5.1.2 Battery test evaluation

BATTERY-TEST

TEST RESULT

VOLTAGE: 12,91V

START CAPACITY: 105%

BATTERY: GOOD

300A DIN >0°C E

The results from the Battery-Test provide the following

information:

R Voltage

R Start Capacity

R Overall battery condition in the form of text:

$ Good battery

$ Good battery / Charge the battery

$ Charge the battery / repeat the Battery-Test

$ Battery unserviceable

$ Battery unserviceable / Short circuit between

battery cells

¶ E provides access to graphical representation of

charge status, starting capacity and battery status.

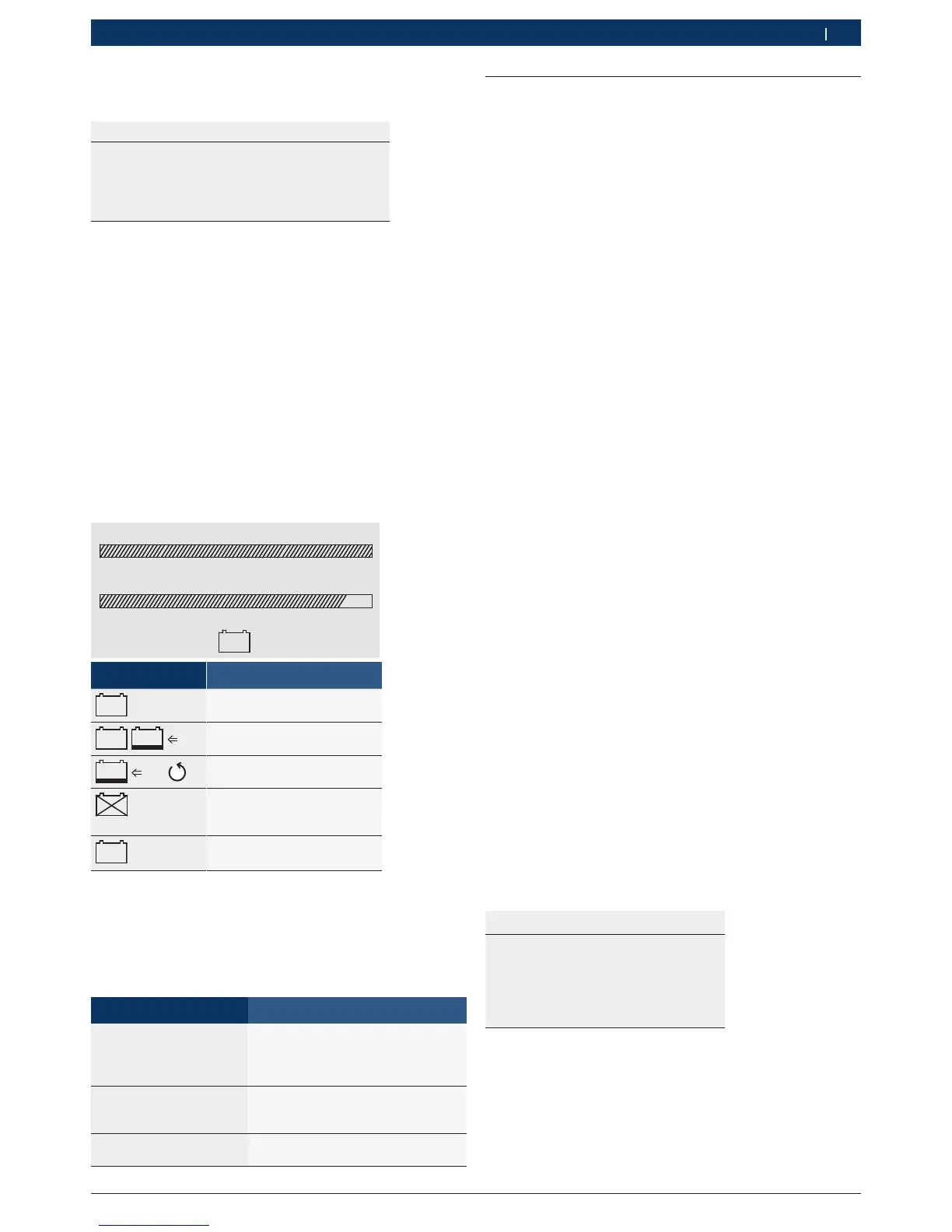

STATE OF CHARGE:

START CAPACITY:

0 50 100%

0 50 100%

+

-

OK

E

Symbol Battery condition

+

-

OK

Good battery

+

-

OK

+

-

Ah

Good battery

Charge the battery

+

-

Ah

Charge the battery

Repeat the Battery-Test

+

-

Battery unserviceable

Short circuit between

battery cells

+

-

?

Check parameters

i The Start output indicates the ratio of the battery’s

measured cold-start current to the entered cold-star-

ting current. The start output may exceed 100 %.

5.1.3 Notes on problems

Message Action to be taken

Battery voltage

interference: Switch off

engine / Radio off/ Elec-

trical equipment off

Switch off electrical equipment

(refer also to Section 4.3) and

repeat battery test

Contact problems:

Check positive terminal /

Check negative terminal

Check connection to battery posts

and clean battery posts if necessary

Check parameter Check parameter

and repeat battery test

5.2 Alternator-Test

The Alternator-Test is carried out in 2 steps.

Step 1 "Regulator Volt"

The generator regulator ensures correct charging during

driving by regulating the final charging voltage (Regu-

lator Volt) of the battery. This final value is recorded

automatically by the BAT 121 as soon as the increase

in voltage reaches the steady state. This final state is

reached sooner when all consumers are switched off.

Step 2 "Ripple"

The battery voltage is characterised by the ripple of a

certain pattern from an intact alternating-current ge-

nerator. Test information is obtained by analysing this

pattern at idle speed in combination with a battery

capable of starting the engine and powering the rear-

window heater.

i Carry out a Batter-test before conducting the Gene-

rator-Test. The connecting terminals of the battery

tester should be connected directly to the poles of

the battery for the Generator-Test as well.

5.2.1 Alternator test procedure

1. Start the alternator test with E.

2. Use the keys and to set the regulator tempera-

ture >0 °C or <0 °C for the Alternator-Test.

3. Then start the engine of the vehicle.

4. Switch off all consumers in the car for Step 1 "Regu-

lator Volt".

i A result can be obtained more quickly for Regula-

tor Volt at a higher engine speed.

5. Switch on the rear-window heater as the consumer

for Step 2 "Ripple".

! The engine must now turn over at the idling speed.

The following information is displayed by the battery

tester (example):

ALTERNATOR-TEST

TEST-RESULT

RIPPLE GOOD

REGULATOR VOLT: 14.22V

GOOD

REGUL. TEMP >0°C

Loading...

Loading...