42

Auxiliary fence

MAKING AN AUXILIARY FENCE:

Certain types of molding need a fence face

e

xtension because of the size and position of the

workpiece. Holes are provided in the fence to

attach an auxiliary fence. The auxiliary fence is

used with the saw in the 0° bevel position only.

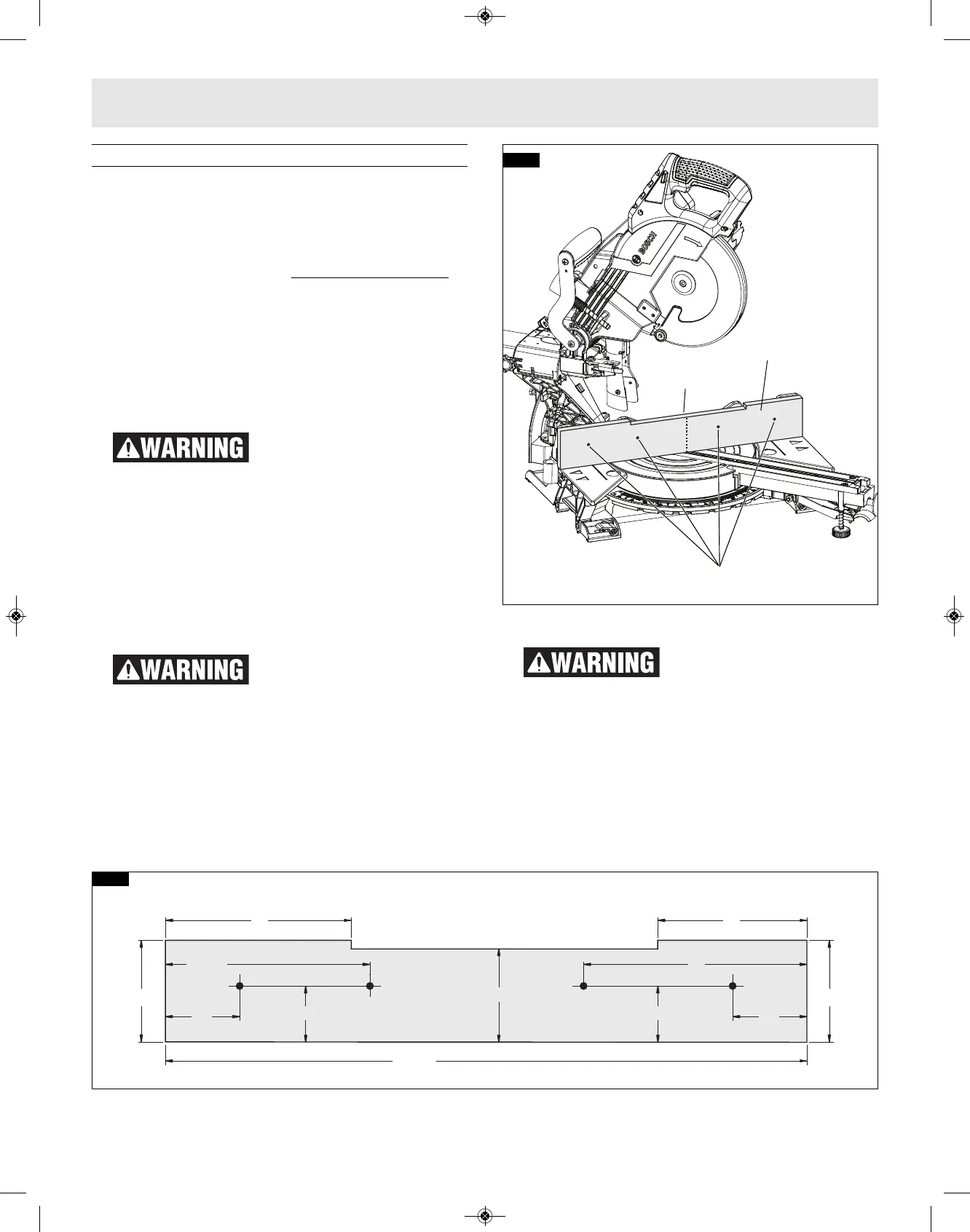

1. Use ¾” thick piece of wood (plywood is prefferd)

to cut an auxiliary fence based on dimensions

shown in Figure 49.

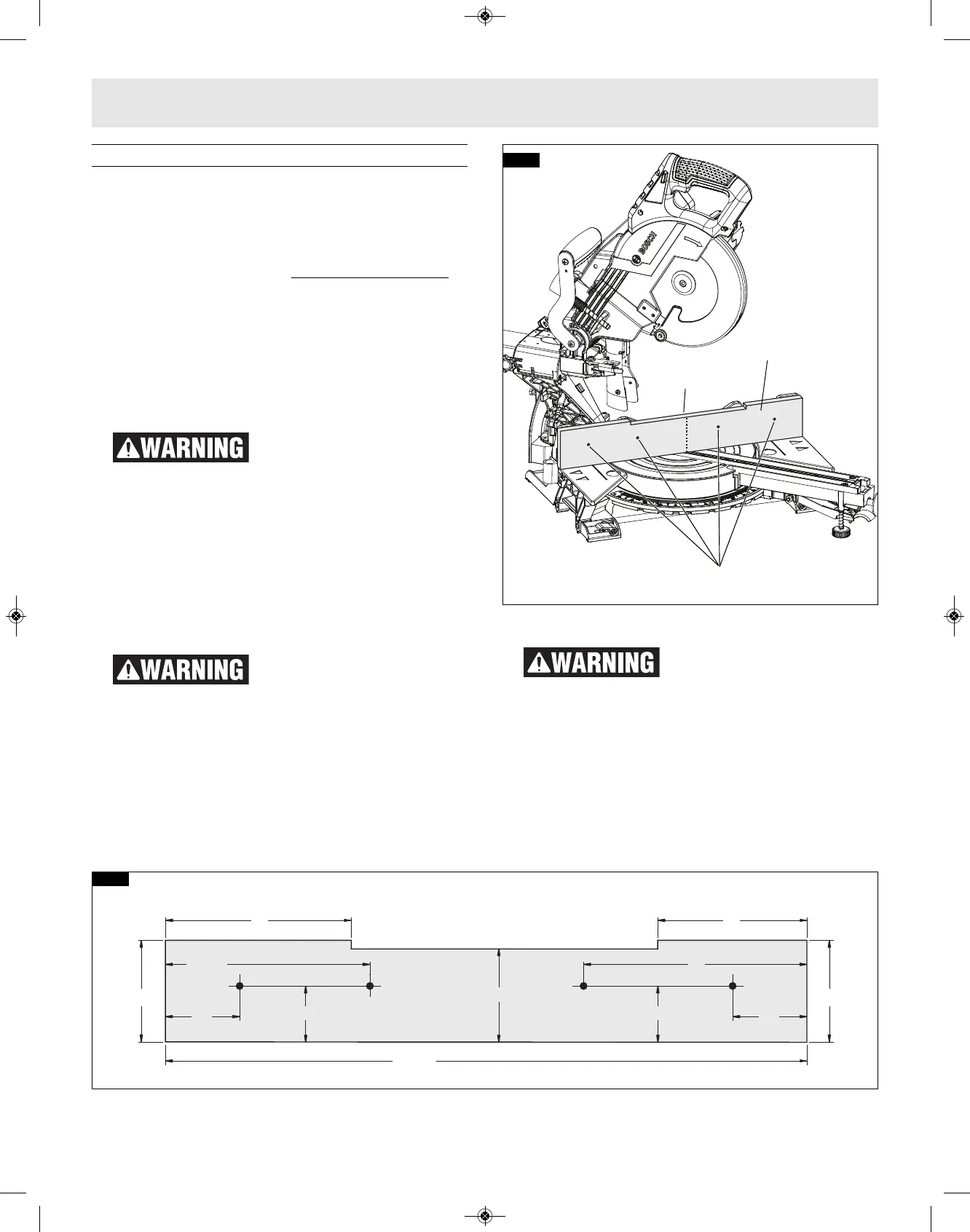

2. Place the auxiliary fence against the miter saw

fence (figure 48). Check that auxiliary fence does

not interfere with head assembly. Check for

interference between the auxiliary fence and the

lower blade guard. Make adjustments as

necessary.

Check for interference

between auxiliary fence and

saw head componenents by performing a dry run.

Fence interference can prevent proper saw

operation and cause injury and/or tool damage.

3. Mark the locations of the support holes on the

wood from the back side of the fence (figure 48).

4. Drill and countersink the holes on the front of the

support board.

To fasten from front of fence:

1. Attach auxiliary fence using four (4) 3/16" x 1-

1/2" long flat head machine bolts. Secure behind

metal fence with washer and #5 machine nuts.

Be aware of the path of the

saw blade. Make a dry run

with the saw Off by conducting a simulated

cutting cycle, and observe the projected path of

the saw blade. Keep hands at least six (6) inches

away from the projected path of the saw blade.

2. Make a full depth cut to create the blade slot.

To fasten from back of fence:

Use minimum 3/4" thick auxiliary fence and 1/4"

round head wood screws (3/4" long).

1. Drill four pilot holes through auxiliary fence and

run screws from rear of metal fence.

Be aware of the path of the

saw blade. Make a dry run

with the saw Off by conducting a simulated

cutting cycle, and observe the projected path of

the saw blade. Keep hands at least six (6) inches

away from the projected path of the saw blade.

2. Make a full depth cut to create the blade slot.

Flat Head Machine

Screws

Auxiliary

Fence

Blade

Slot

Loading...

Loading...