48

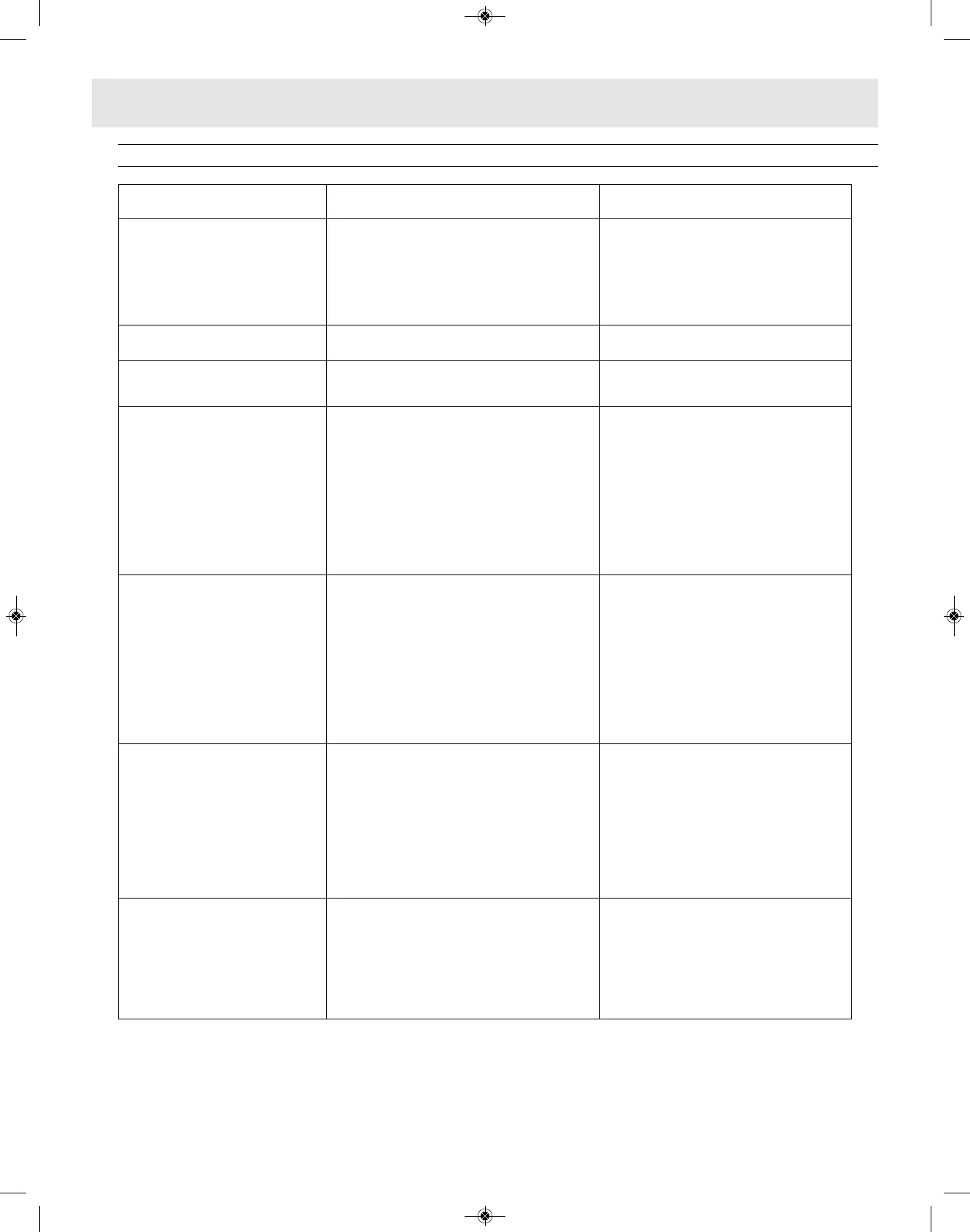

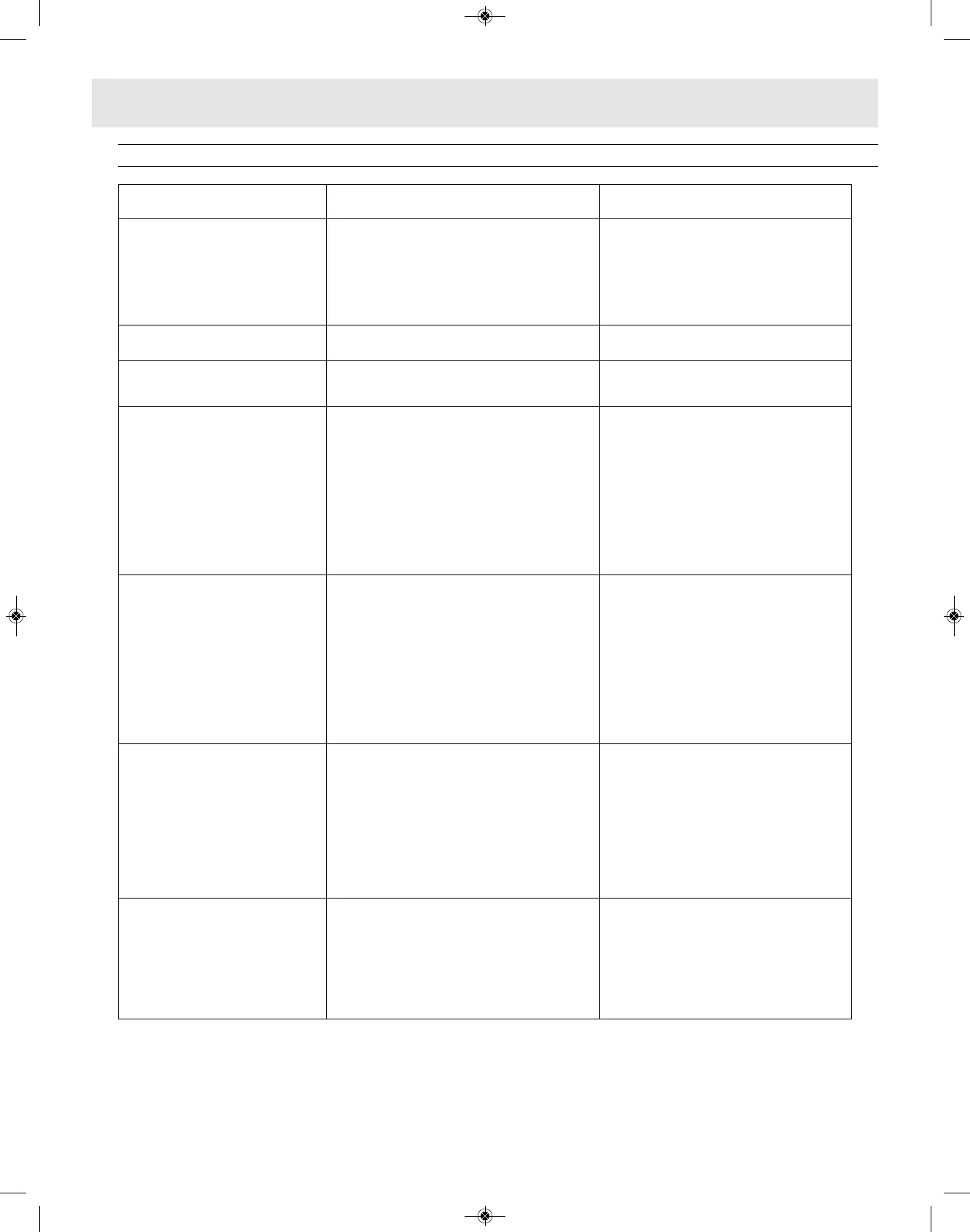

Troubleshooting

Troubleshooting Guide - General

P

ROBLEM

C

AUSE

C

ORRECTIVE ACTION

H

ead assembly does not

bevel to desired position.

B

evel lock is engaged.

-

Pull the bevel lock forward to

unlock the head assembly.

Blade hits table. 1. Misalignment. - Authorized service.

Angle of cut not accurate. 1. Angle stops at 0° or 45° need

adjustment.

- See Adjustments section

(pages 20-24).

Cannot rotate table to

change miter angle.

1. Miter lock knob is tightened.

2. Miter detent lever is engaged with

a detent (slot) in detent plate.

3. Sawdust accumulation.

- Turn miter lock knob

counterclockwise to loosen.

- Pull up on miter detent lever to

disengage from detent slot

(see page 32).

- Vacuum or blow out dust

around turntable; wear eye

protection.

Head assembly will not

fully raise or blade guard

will not fully close.

1. Head assembly lock pin is

engaged.

2. Sawdust accumulation.

3. Sawdust accumulation.

- Pull out lock pin, allowing head

assembly to go up (see page

19).

- Clean head assembly.

- Authorized service.

Blade binds, jams, burns

wood. Rough cuts.

1. Improper operation.

2. Dull blade.

3. Improper blade.

4. Bent blade.

- See Saw Operations section.

- Replace or sharpen blade.

- Replace with 8-1/2” diameter

blade designed for material

being cut.

- Replace blade.

Head assembly slides

forward and back when

making a chop cut.

Slide rail lock knob is disengaged. - Rotate Slide rail lock knob

clockwise to lock head in

place.

Loading...

Loading...