29

DISASSEMBLY PROCEDURE

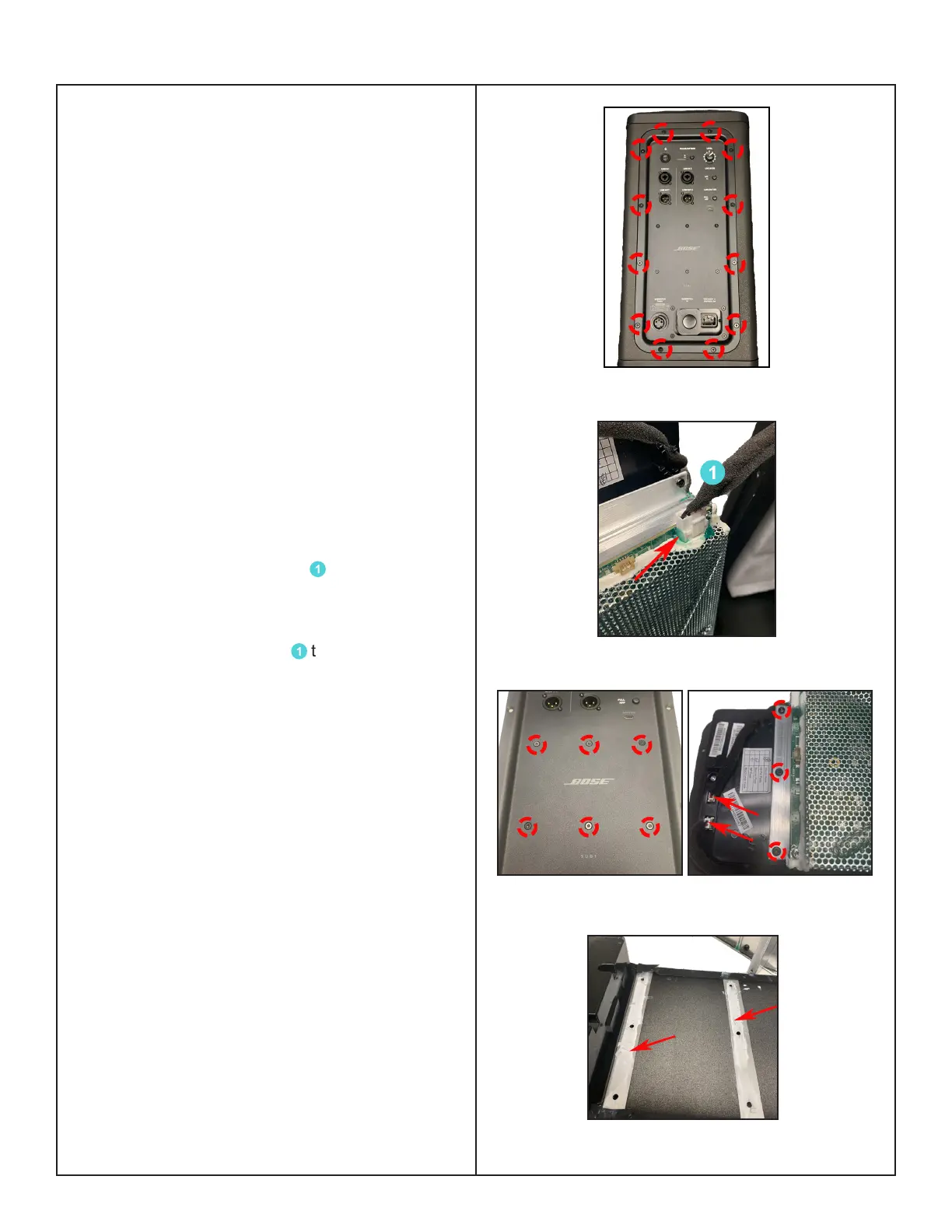

Figure 4. I/O Panel Screws Removal

Sub2 Power Stand Procedures

CAUTION: The SMD integrated circuits used

on the Main-I/O Board are extremely sensitive

to ESD damage. Be sure to use an approved

and tested ESD strap that is properly grounded

to your work bench before attempting disas-

sembly or repair of the Sub2 Powered Bass

Module.

1. I/O Panel Assy Removal

1.1 Remove the 14 screws securing the

I/O Panel Assy as indicated in Figure 4.

Note: Be careful to not cause cosmetic

damage to the unit.

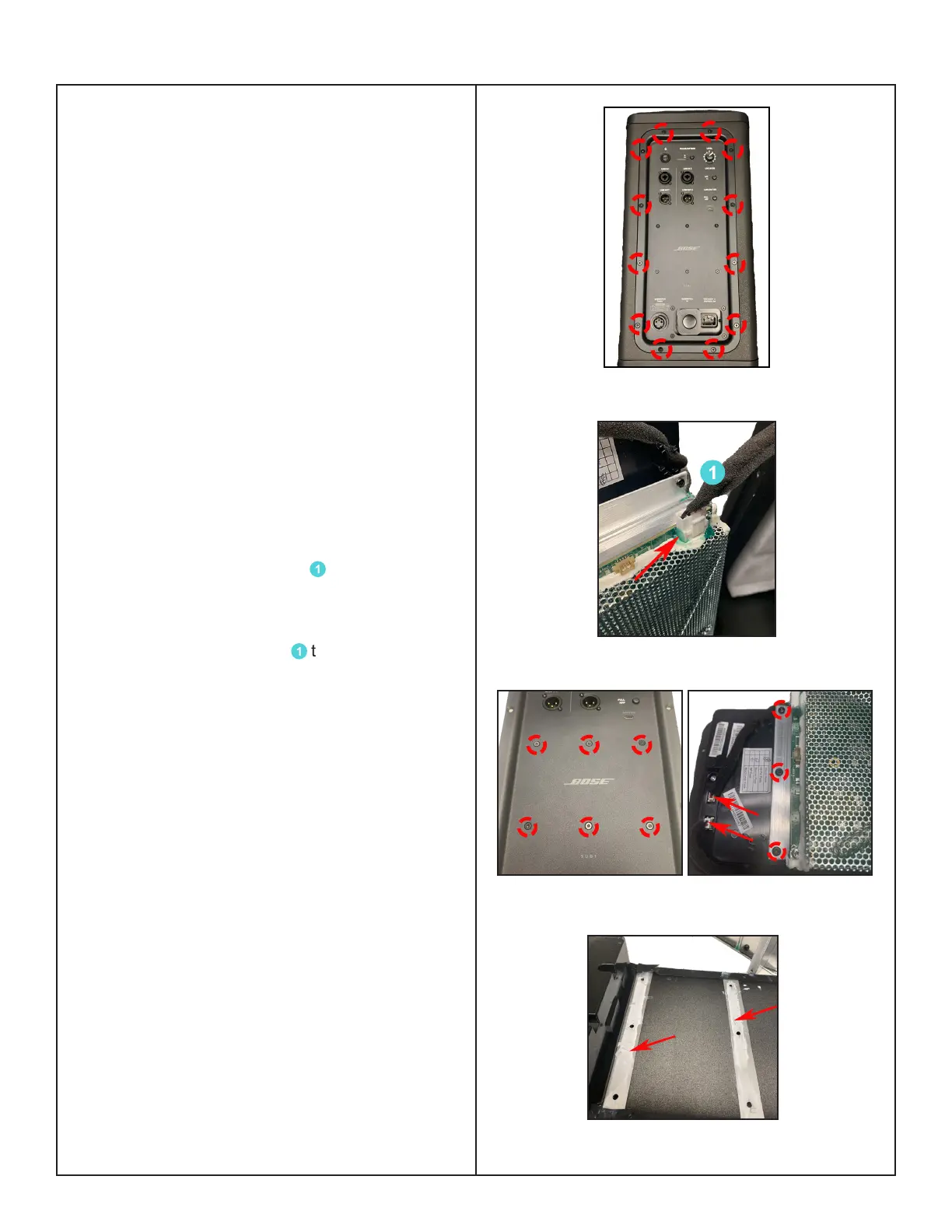

1.2 Incline the Power stand to let the I/O

panel assy go downwards.

1.3 Remove the green adhesive with IPA

(Isopropyl alcohol) from the

1

cable's

connections as red arrow indicated in Figure

5.

1.4 Disconnect the cable

1

that are attaching

the Woofer. Figure 5.

2. Power-Amp Board Removal

2.1 Perform procedure 1.

2.2 On the front of the I/O panel assy, remove

the 6 screws as indicated in Figure 6 (left) and

turn it over to remove the 3 screws securing

the Power-Amp board. Figure 6 (right).

2.3 Detach 2 cables' connections as red arrow

indicated in Figure 6 (right).

Re-assembly Note: The old Heat Sink ther-

mal grease must be removed with isopropyl

alcohol and the new thermal grease, GAP

FILLER, THERMAL, part number 749859-

0020 MUST be used during board replace-

ment. Failure to use the correct thermal

grease WILL cause thermal failures. Figure 7.

Figure 5. Green Adhesive & Cable Removal

Figure 6. Power-Amp Board Screws Removal

Figure 7. Heat Sink Thermal Grease

Loading...

Loading...