8

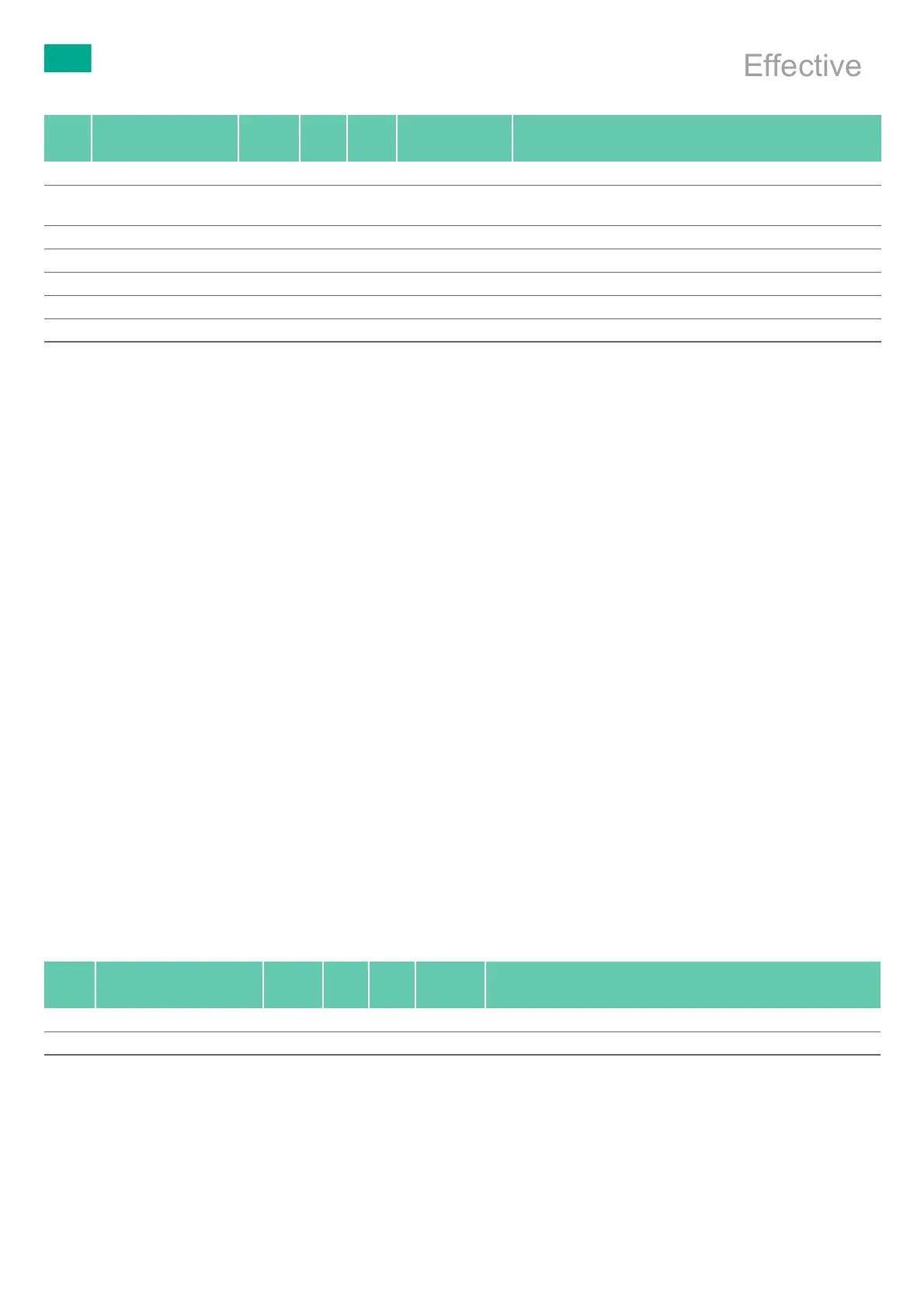

7.7 Manual cleaning with wipe disinfection

DW: Drinking water

FD–W: Fully desalinated water (demineralized, microbiological, at least of drinking water quality)

RT: Room temperature

* Suitable enzyme solution: Helizyme, Cidezyme (the latter being used for validation purposes)

► Do not clean the product in a ultrasonic bath and do not immerse the

product in any fluids. Let any fluid incursions drain out immediately,

otherwise there is a danger of corrosion and loss of function.

Phase I

► Move flexible components (such as sleeves) during cleaning.

► Clean the product under running water, using a suitable plastic clean-

ing brush until all visible residues have been removed from the sur-

faces.

► Brush cannulation with cleaning brush TA011944 and difficult to

access surfaces with a suitable plastic cleaning brush for at least 1 min.

Phase II

► Follow the operating instructions of the enzyme cleaner with regard to

correct concentration, dilution, temperature and water quality.

► Spray products with a pH neutral enzyme solution, let soak in for at

least 2 minutes and then wipe off.

Phase III

► Move flexible components (such as sleeves) during cleaning.

► Rinse product under running tap water for at least 5 minutes.

► Follow the operating instructions of the enzyme cleaner with regard to

correct concentration, dilution, temperature and water quality.

► Remove contamination with a lint-free cloth or soft brush moistened

with enzyme cleaner.

► Rinse flexible components (such as sleeves) and cannulations for

20 seconds with the water pistol (cold water, at least 2.5 bar).

► After manual cleaning, check visible surfaces and areas of flexible com-

ponents for residues.

► If necessary, repeat the cleaning process (phase 1 to 3).

Phase IV

► Dry the product in the drying phase with suitable equipment (such as

lint-free cloths, pressurized air).

Phase V

► Wipe all surfaces of the product with a single-use disinfecting wipe.

Phase VI

► Rinse disinfected surfaces after the prescribed reaction time for at least

1 minute under running demineralized water.

► Drain any remaining water fully.

Stage VII

► Dry the product in the drying phase with suitable equipment (such as

lint-free cloths, pressurized air).

7.8 Automatic cleaning/disinfection with manual pre-cleaning

Note

The cleaning and disinfection device must fundamentally have a tested

efficacy (such as FDA approval or CE label pursuant to DIN EN ISO 15883).

Note

The cleaning and disinfection machine used for processing must be serviced

and checked at regular intervals.

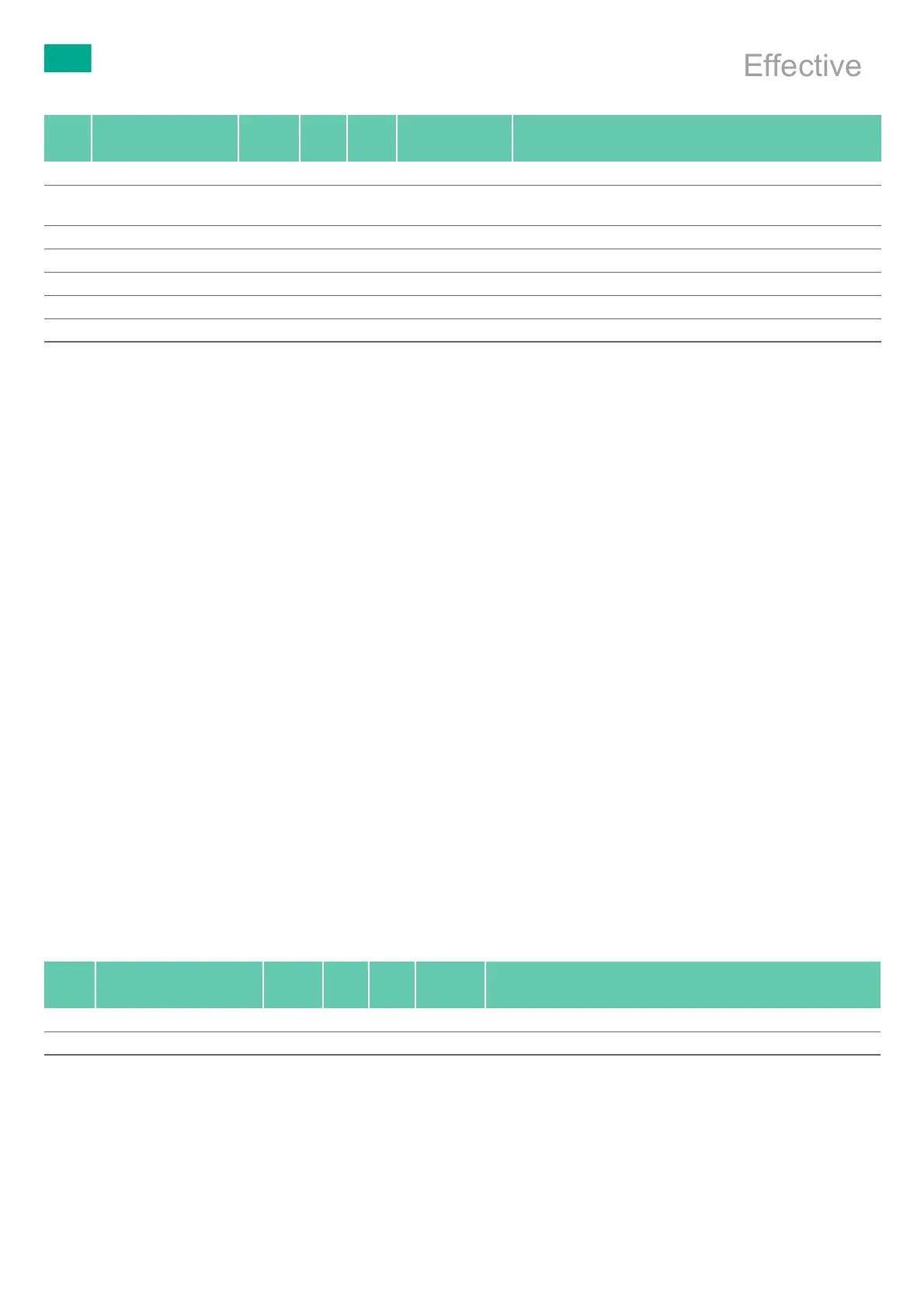

7.8.1 Manual pre-cleaning with a brush

D–W: Drinking water

RT: Room temperature

► Do not clean the product in a ultrasonic bath and do not immerse the

product in any fluids. Let any fluid incursions drain out immediately,

otherwise there is a danger of corrosion and loss of function.

Phase I

► Move flexible components (such as sleeves) during cleaning.

► Thoroughly clean the product under running water.

Phase II

► Move flexible components (such as sleeves) during cleaning.

► Brush cannulation with cleaning brush TA011944 and difficult to

access surfaces with a suitable plastic cleaning brush for at least 1 min.

► After manual pre-cleaning, check visible surfaces for residue and

repeat the pre-cleaning process as required.

Phase Step T

[°C/°F]

t

[min]

Conc.

[%]

Water quality Chemicals

I Pre-cleaning RT (cold) ≥2 - D-W Until visually clean

II Cleaning with enzyme

solution

RT (cold) ≥2 0.8 D–W pH-neutral*

III Intermediate rinse RT ≥5- D-W –

IV Drying RT - - - -

V Wipe disinfection - >1 - - Meliseptol HBV wipes 50 % Propan-1-ol

VI Final rinse RT (cold) 0.5 - FD–W -

VII Drying RT - - - -

Phase Step T

[°C/°F]

t

[min]

Conc.

[%]

Water

quality

Chemistry/Note

I Rinsing RT (cold) - - D–W Until visually clean

II Brushes RT (cold) - - D–W Until visually clean

Document No.: TA014436 - Version: 1.0 - Document ID: SOP-AIC-5002244 Date/Time Printed/Viewed: 2022-04-13 16:01 (CET)

Effective

Loading...

Loading...