www.bresser.de

2.3.7 Material compatibility

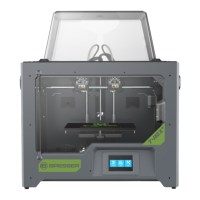

The printer has two independent extruders and supports PLA, ABS, HIPS and PVA.

Combo mode:

PVA+PLA HIPS+ABS PLA+PLA ABS+ABS

BRESSER materials give the best results, but BRESSER T-REX 2 also supports the

use of other brands of materials. All BRESSER materials have been tested. The best

test results were achieved with REXprint.

PVA filament is water soluble and has strong water absorbing properties. The

filament may become soft after absorbing water, which may cause misprints. Place

the PVA filament in a dry box during printing. PVA must be kept closed tightly and

dry.

To achieve the best results, the appropriate settings must be made for each material.

When REXprint is used to slice the model, these settings are made automatically

when the correct extruder and suitable material are selected.

Adjustment of material parametres

Different brands of filament have different material properties. Therefore, it is

recommended to use the expert mode to fine-tune the parametres so that a good

print quality is guaranteed.

Determining the thickness of the first layer adhesion to the platform improves

when the first filament layer is applied.

Set the platform temperature for printing small PLA models at 30°C or

whenever the ambient temperature exceeds 25°C.

Set the platform temperature for printing large PLA models at 50° C, or

whenever the ambient temperature falls below 10° C.

The open pressure chamber is suitable for PLA prints. Remove the top cover.

The closed pressure chamber is suitable for ABS prints. Close the top cover to

prevent the filament from breaking.

It is recommended to reduce the normal printing speed by 40°%. Place the

PVA filament in a dry box so that no water is absorbed from the air, which can

cause misprints.

Loading...

Loading...