49

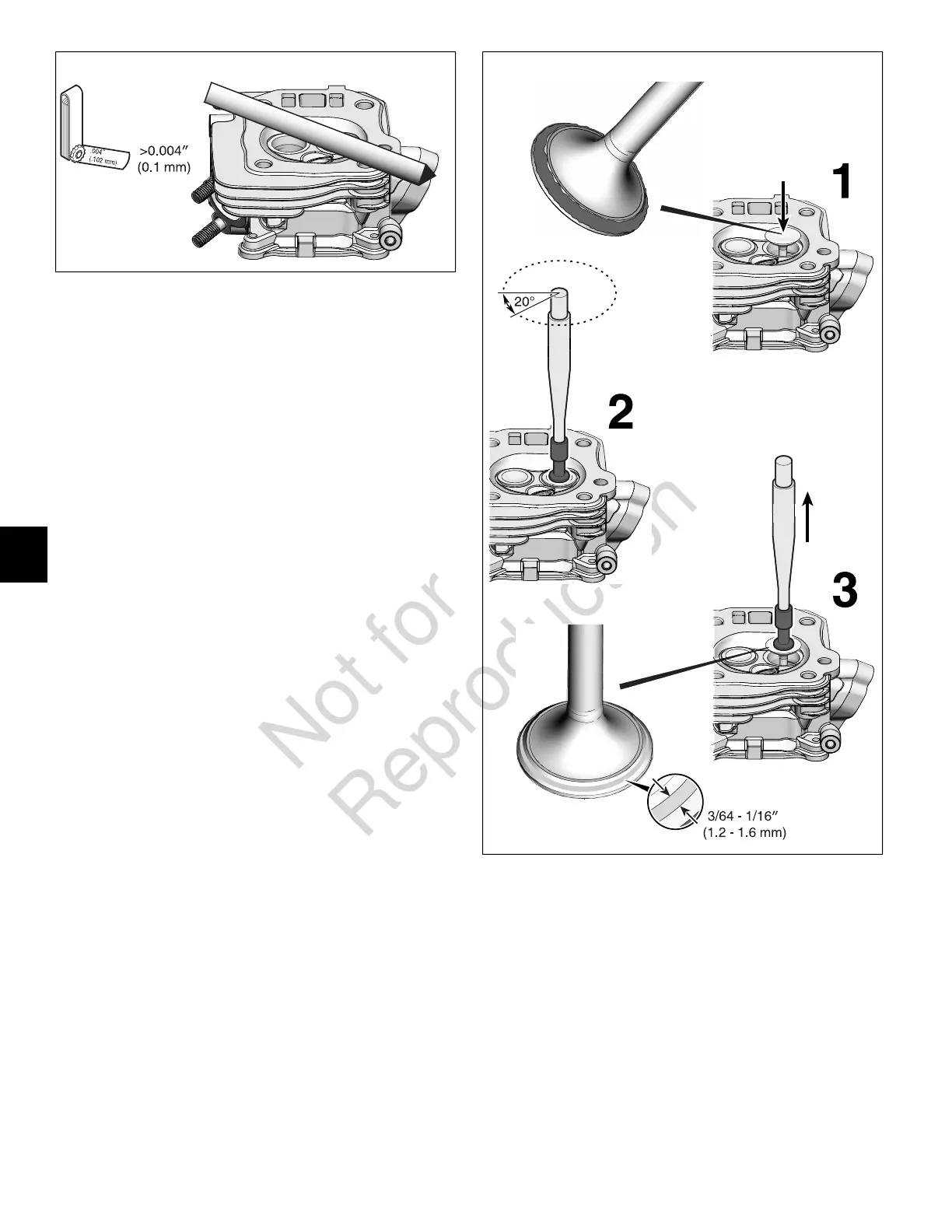

2. If head passes visual inspection, check valve guides

for wear. If valve guides meet or exceed the reject

dimension shown in

Section 13 - Engine

Specifications

, replace the cylinder head.

3. Inspect valves for wear or damage. If slight wear is

found, lap the valve and seat as instructed in the

following steps. If excessive wear or damage is found,

replace cylinder head.

Note:

Valve faces can be resurfaced on a commercially

available valve grinder. However, Briggs & Stratton does

not recommend this practice because the quality of the

resurfacing may be insufficient.

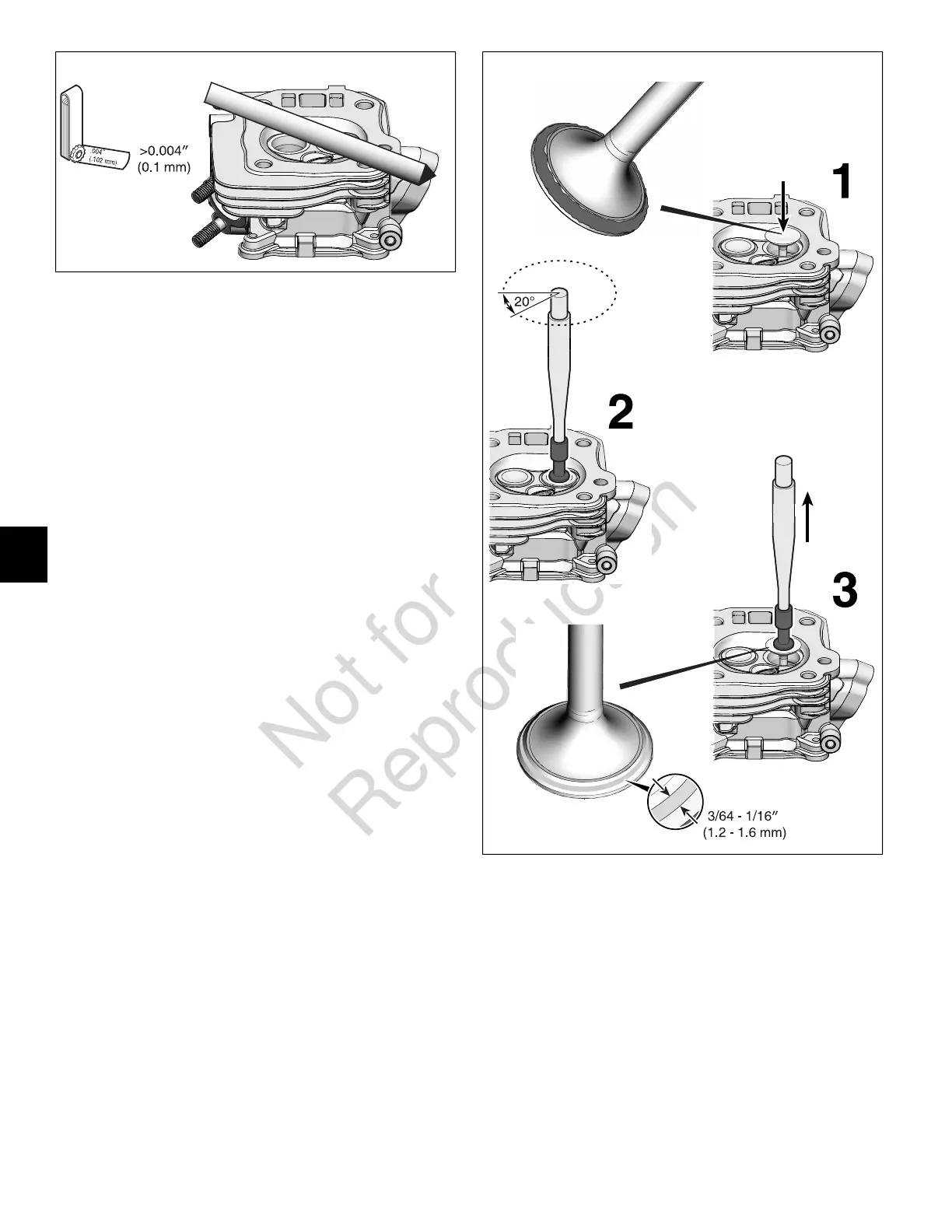

4. Place a small amount of lapping compound #94150

around the valve face of one valve. Make sure that

lapping compound only comes into contact with the

valve face and valve seat.

5. Oil the valve guide and valve stem and then insert the

valve into the cylinder head.

6. Using Valve Lapping Tool #19258, rotate the valve

clockwise and counterclockwise, approximately 20 °

each way. Continue this action for a short period of

time.

7. Remove the valve. Use a rag dipped in mineral spirits

to clean the valve face. Inspect the surface made by

the lapping compound. Make sure that the width of the

lapped surface is equal around the entire valve and

within 3/64 - 1/16" (1.2 - 1.6 mm). If both conditions are

not met, replace the valve.

8. Repeat this procedure for the remaining valve.

50

9. Use a rag dipped in mineral spirits to thoroughly clean

all lapping compound from the valves and cylinder head.

Assemble Cylinder Head

1. Install push rod guide plate (W) into cylinder head (G)

and secure with rocker arm studs (U). Torque rocker

arm studs to value listed in

Section 13 - Engine

Specifications

.

2. Lightly coat valve stems with lubricant, then insert

valves (Q) into cylinder head (G).

Note:

Do Not get lubricant on valve face, valve seat, or

exposed end of valve stem.

56 BRIGGSandSTRATTON.COM

7

Loading...

Loading...