Remove Flywheel

1. Remove blower housing (J) as instructed in

Adjust

Armature Air Gap

found in Section 2.

2. Remove flywheel guard (B).

3. Rotate flywheel (E) so that magnet is away from

armature (M).

4. Remove the two armature screws (L) and then remove

the armature.

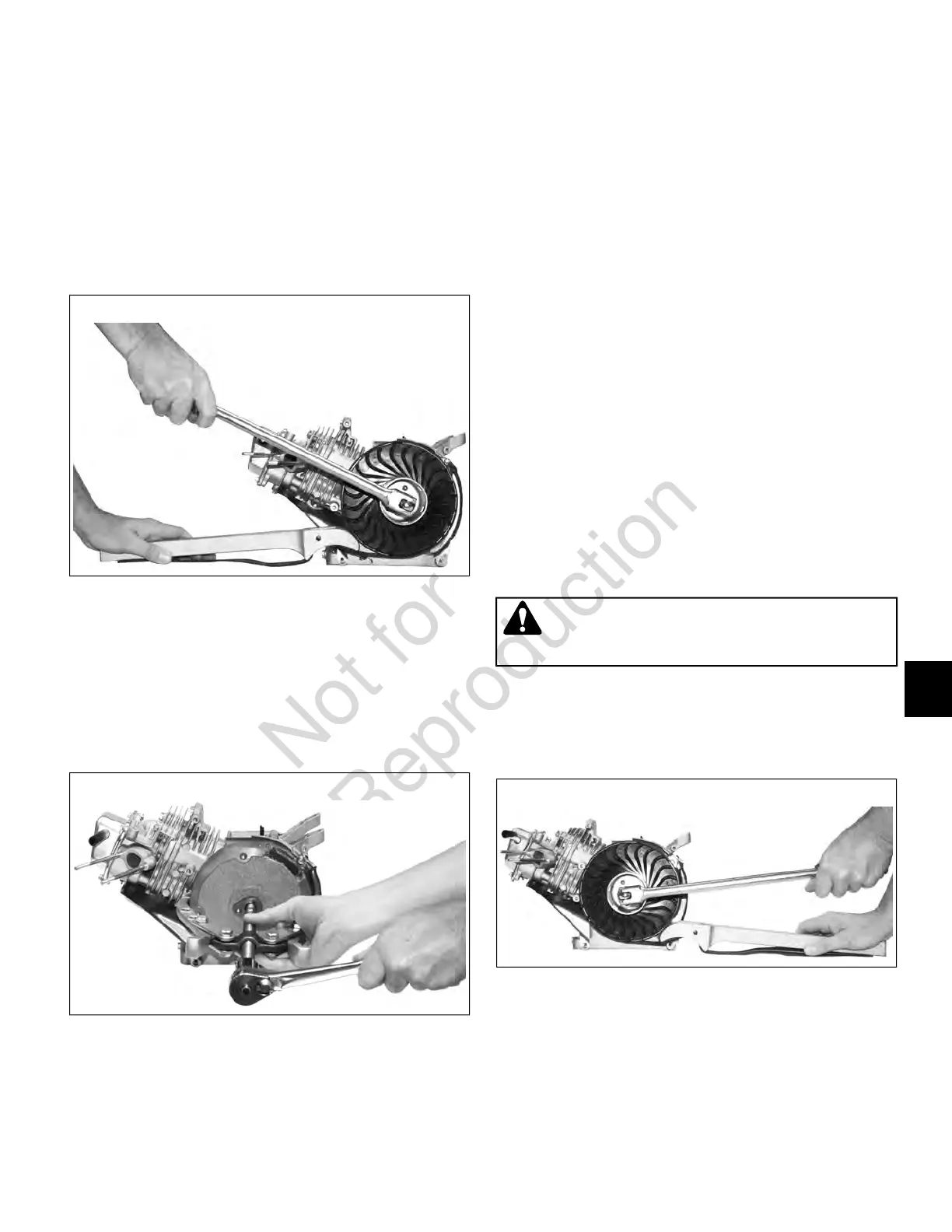

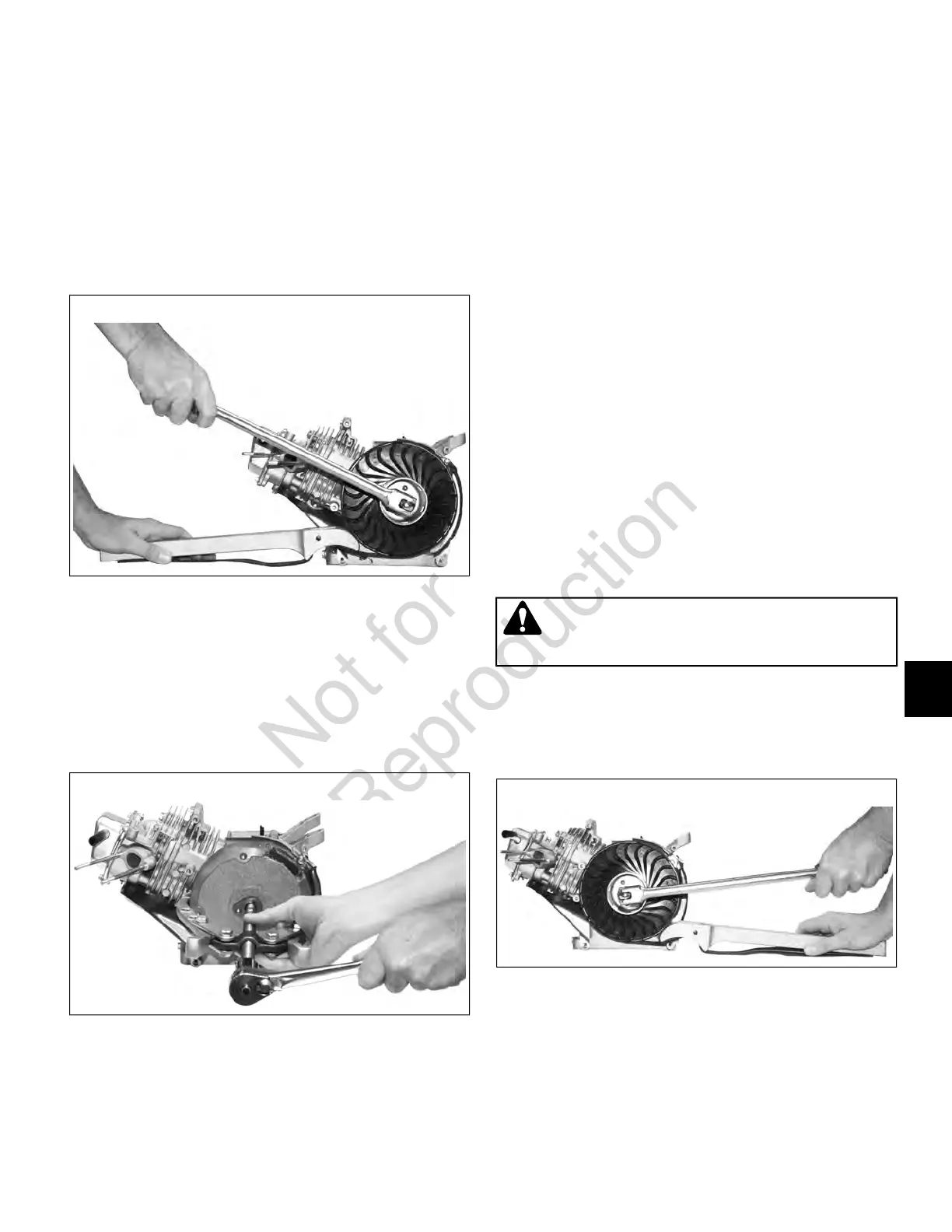

5. Using a strap wrench, socket and breaker bar, remove

flywheel nut (H).

66

6. Remove flywheel cup (G) and fan (F).

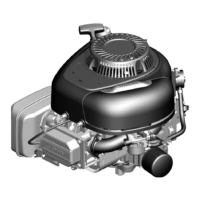

7. When flywheel does not have drilled and tapped puller

holes, remove flywheel from crankshaft (D) with a gear

puller, as shown.

When flywheel has drilled and tapped puller holes,

remove flywheel from crankshaft (D) with flywheel puller

#19203. Thread flywheel nut flush with end of crankshaft

before installing puller.

67

Inspect Flywheel

Inspect flywheel key (A) for partial or complete sheering.

Inspect flywheel (E) for cracks, burrs on taper or keyway

and distortion of keyway.

Inspect taper on crankshaft (D) for burrs, rust or other

damage.

Inspect fan (F) for cracks and broken fins.

If parts are damaged, replace with new parts.

Install Flywheel

1. Clean flywheel taper (E) and crankshaft taper (D) of

grease, oil and dirt.

2. Install key (A) into keyway of crankshaft.

NOTICE

Use only an original Briggs & Stratton flywheel

key.

3. Slide flywheel (E) onto crankshaft (D) with keyways

aligned.

4. Install fan (F) against flywheel making sure that hole in

fan fits around boss on flywheel. When fan is installed

correctly, it will fit flush against the flywheel at all points.

WARNING

DO NOT use an impact wrench to install flywheel.

5. Install cup (G) and flywheel nut (H).

6. Using a strap wrench, socket and torque wrench, torque

flywheel nut to the value listed in

Section 13 - Engine

Specifications

.

68

7. Install flywheel guard (B) and secure with top screw

(C). Align bottom hole of flywheel guard with mounting

hole in cylinder. Do not install the bottom screw at this

time.

8. Install armature (M), adjust armature air gap, and install

blower housing (J) as instructed in

Adjust Armature Air

Gap

found in Section 2.

67

9

Loading...

Loading...