Cylinder

Inspect and Measure Cylinder

1. Using a plastic scraper, remove all traces of head

gasket and cover gasket material.

• Visually check cylinder for cracks, stripped threads,

and bore damage. Bore damage, if not severe, may

be corrected by reconditioning or resizing.

• If cracks are found, replace the cylinder.

• Stripped threads can sometimes be repaired using

a helicoil, but if multiple holes have thread damage,

replace the cylinder.

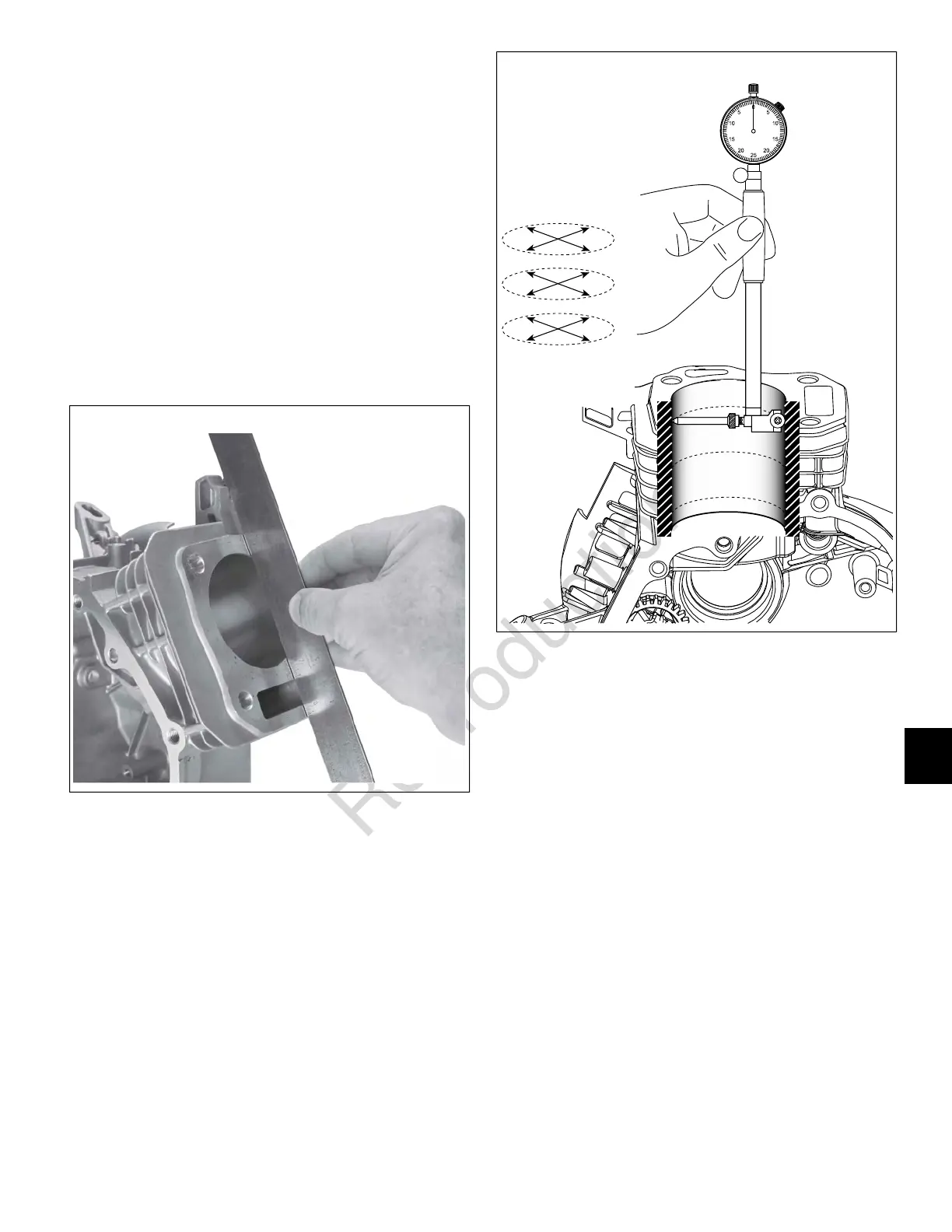

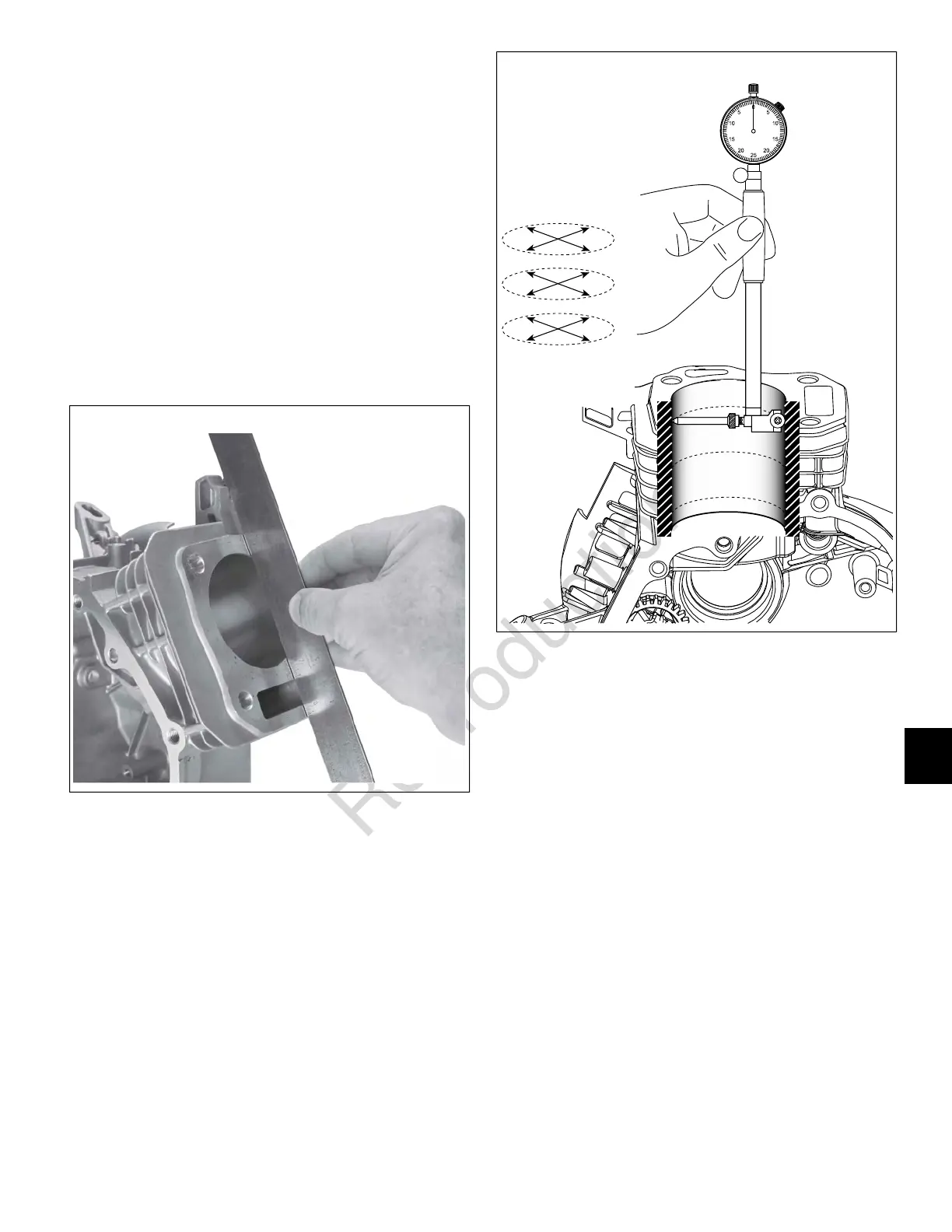

2. Using a straight edge, check across cylinder head

mounting surface for distortion. If mounting surface is

distorted more than 0.004” (0.1 mm), the cylinder must

be replaced.

71

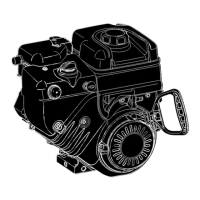

3. Using a Dial Bore Gauge #19487 (preferred), or a

Telescoping Gauge #19485 and Dial Caliper #19609,

measure the diameter of the bore. If necessary,

recondition or resize the bore as described below.

72

Take two measurements (90° apart) at the top, center,

and bottom of the piston ring travel.

Compare measurements to the standard cylinder bore

size provided in

Section 13 - Engine Specifications

.

Recondition Cylinder Bore

If cylinder bore is within specification and shows no signs

of scoring or other damage, it can be reconditioned using

a rigid hone with finishing stones to restore the proper

crosshatch angle.

The correct crosshatch of approximately 45° ensures proper

lubrication and piston ring break-in.

73

10

Loading...

Loading...