3-33

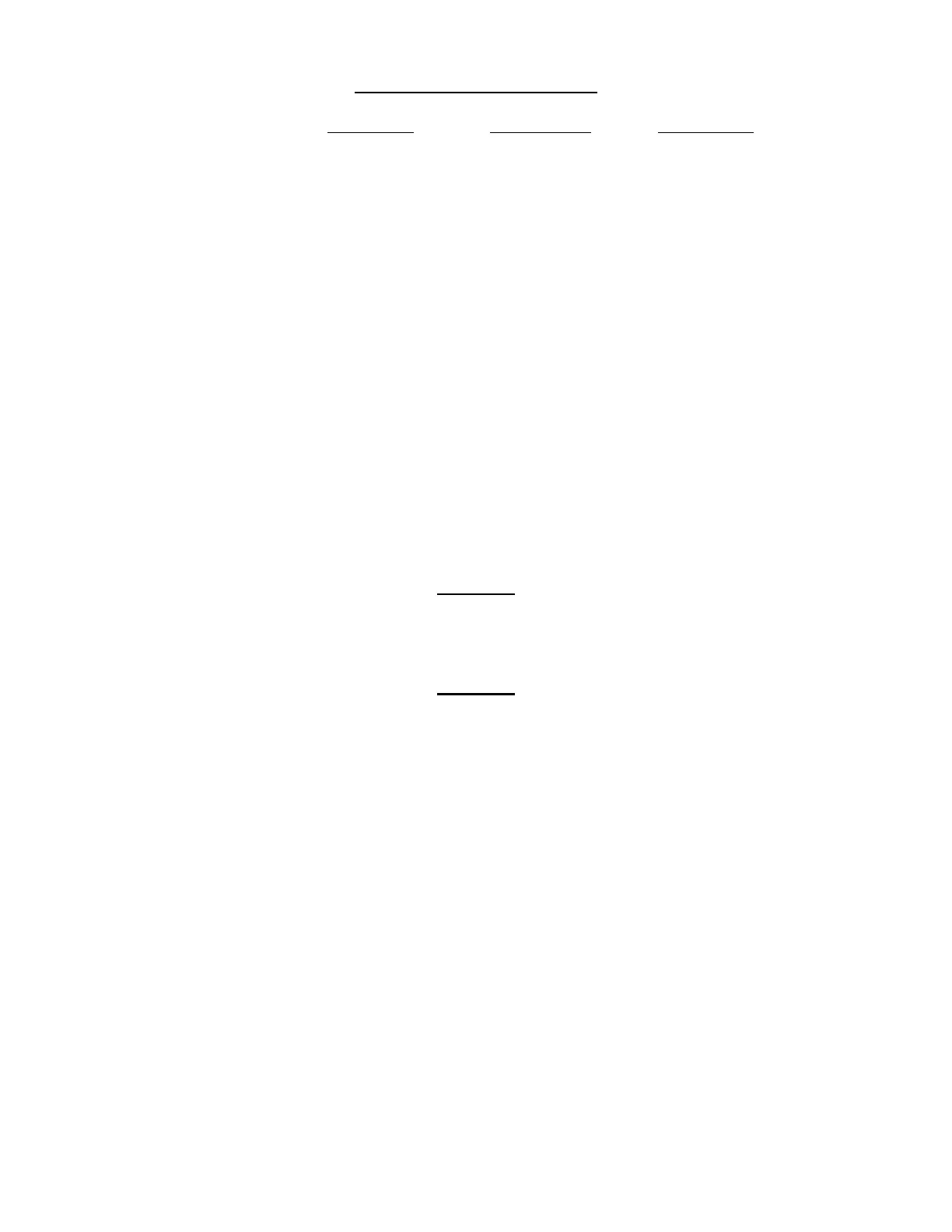

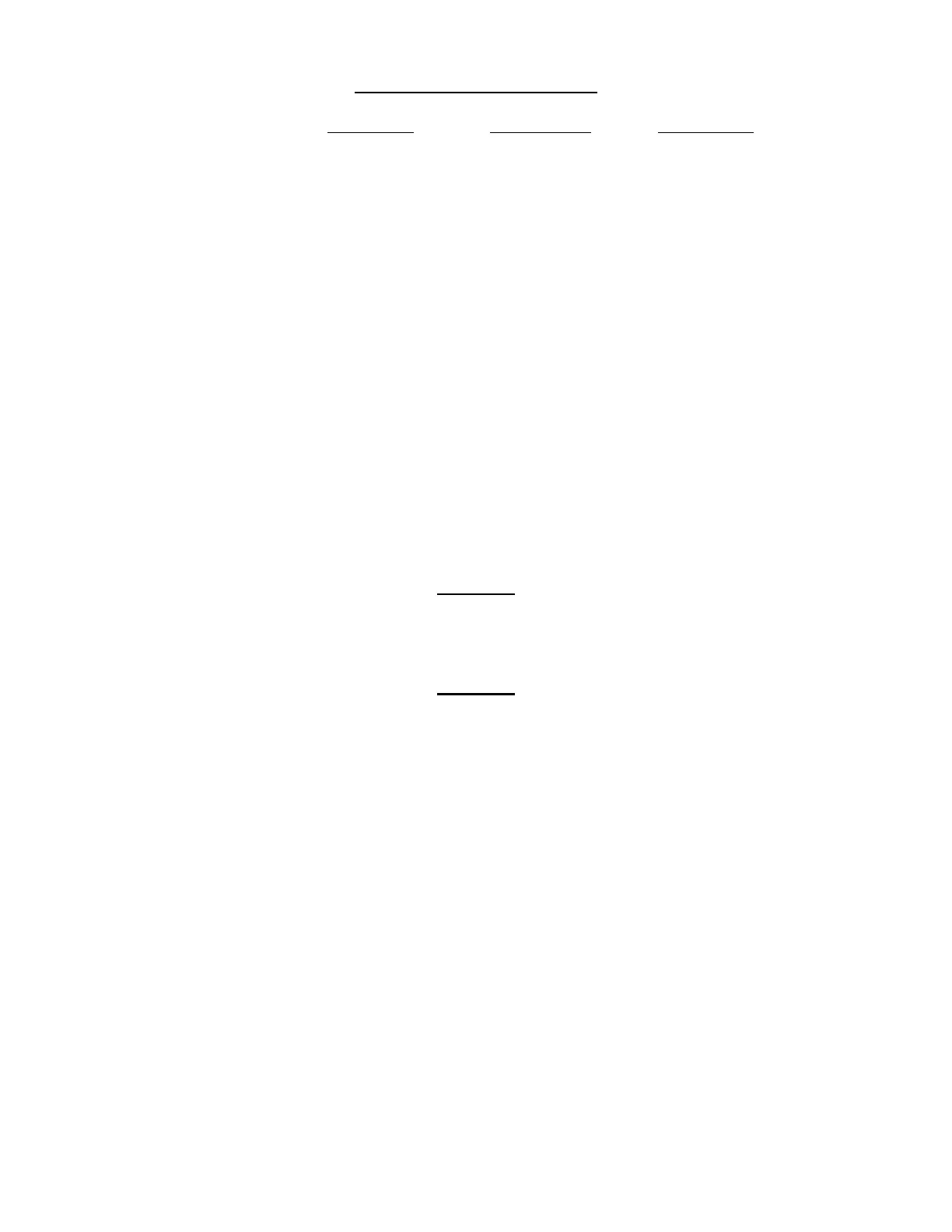

HYDRAULIC OILS FOR IC-600

AMBIENT TEMP RANGE: -40° to 75°F

-15° to 110°F 50° to 130°F

(40° to 24°C) (26° to 43°C) (10° to 54°C)

POUR POINT: -40°F MAX -15°F MAX 0°F MAX

(-40°C) (-26°C) (-18°C)

VISCOSITY INDEX: 140 MIN 95 to 100 95 to 100

VISC. SSU @ 100°F: 200 MAX 230 MAX 340 MAX

SSU @ 210°F: 44 MIN 47 MIN 53 MIN

EXAMPLES:

MOBIL DTE-13 MOBIL AW-46 MOBIL AW-68

MOBIL UNIV.-ATF MOBIL DTE-25 MOBIL DTE-26

TEXAMATIC TYPE F CONOCO SUPER 46 CONOCO SUPER 68

TEXACO HD 46 TEXACO HD 68

OTHER REQUIREMENTS: Must contain rust and oxidation inhibitor, and antifoam & antiwear

agents. Must pass Vickers Vane Pump Test.

The IC-600 is factory-filled with hydraulic oil for the -15° to 110°F (-26° TO 43°C) range. If sig-

nificant portions of run time are spent operating below 20°F (-7°c) or above 100°F (43°C), the oil

should be replaced with an extreme temperature oil.

CAUTION

Never add kerosene or other thinners to hydraulic oil. These fluids have low aniline

points and consequently will cause rapid deterioration of certain packings and seals in

the hydraulic system.

CAUTION

Serious damage to the pumps will result if it is run with insufficient oil level in the reser-

voir or if the pumps are allowed to cavitate.

Observe the operation of the machine. If the oil is too cold (below 40°F (5°C)), the machine will

operate at slower speeds due to the increased viscosity of the fluid. It should be warmed up

further to prevent damage to hydraulic components before sustained hard work is attempted. If

the oil is too hot (above 210°F (99° C)), bleed-by leakage will increase, pump efficiency will go

down, and moving parts may not be properly lubricated. If operating temperature continues to

be excessive, rapid deterioration of the oil will result, and moving parts & seals will wear more

quickly. The cause of the excess heat should be determined and corrected. The hydraulic

temperature in the tank can be monitored on the dash display.

Loading...

Loading...