44

ZTKS0162 / Z31928 / 04

Troubleshooting

Continued from page before

Continued on next page

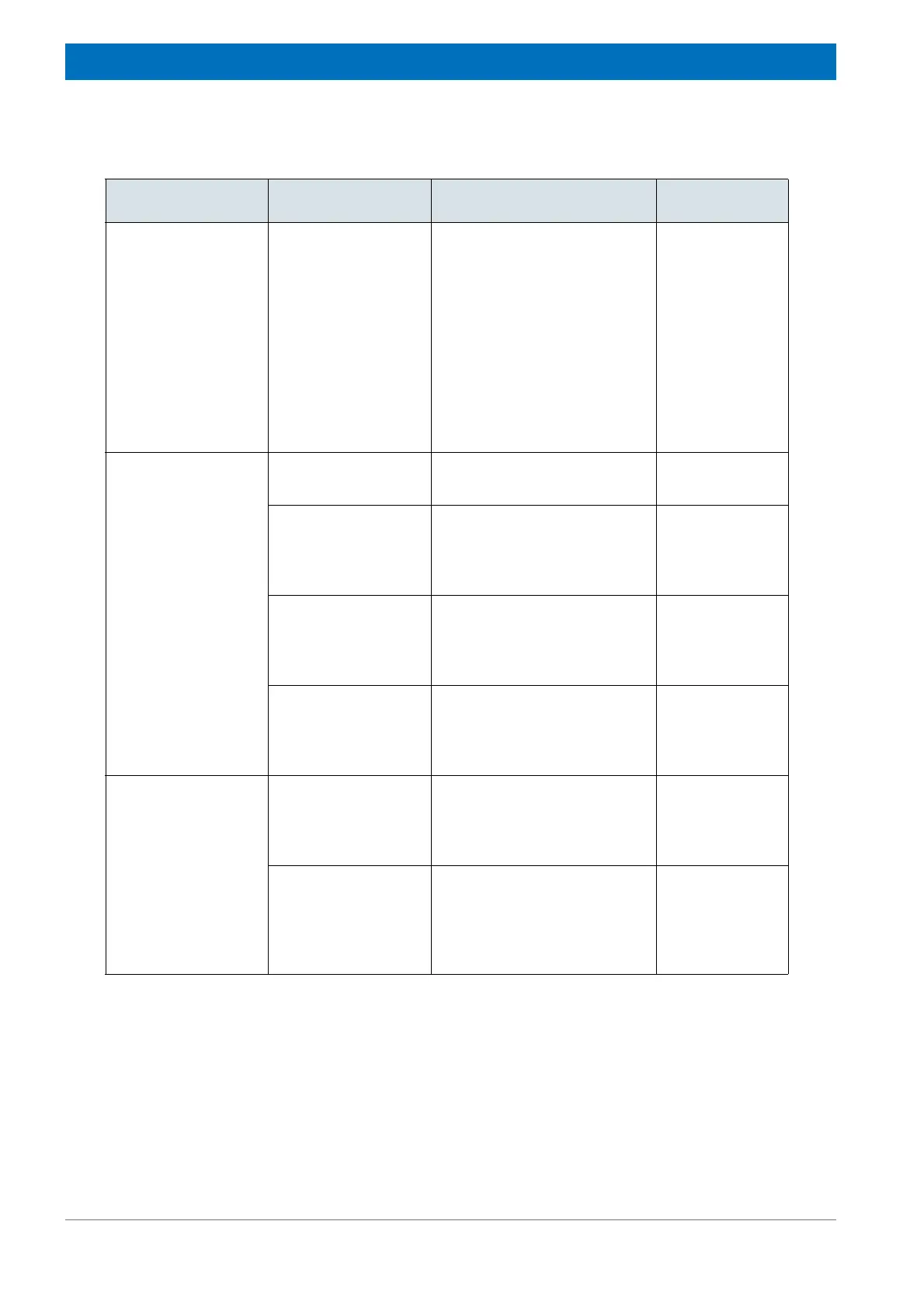

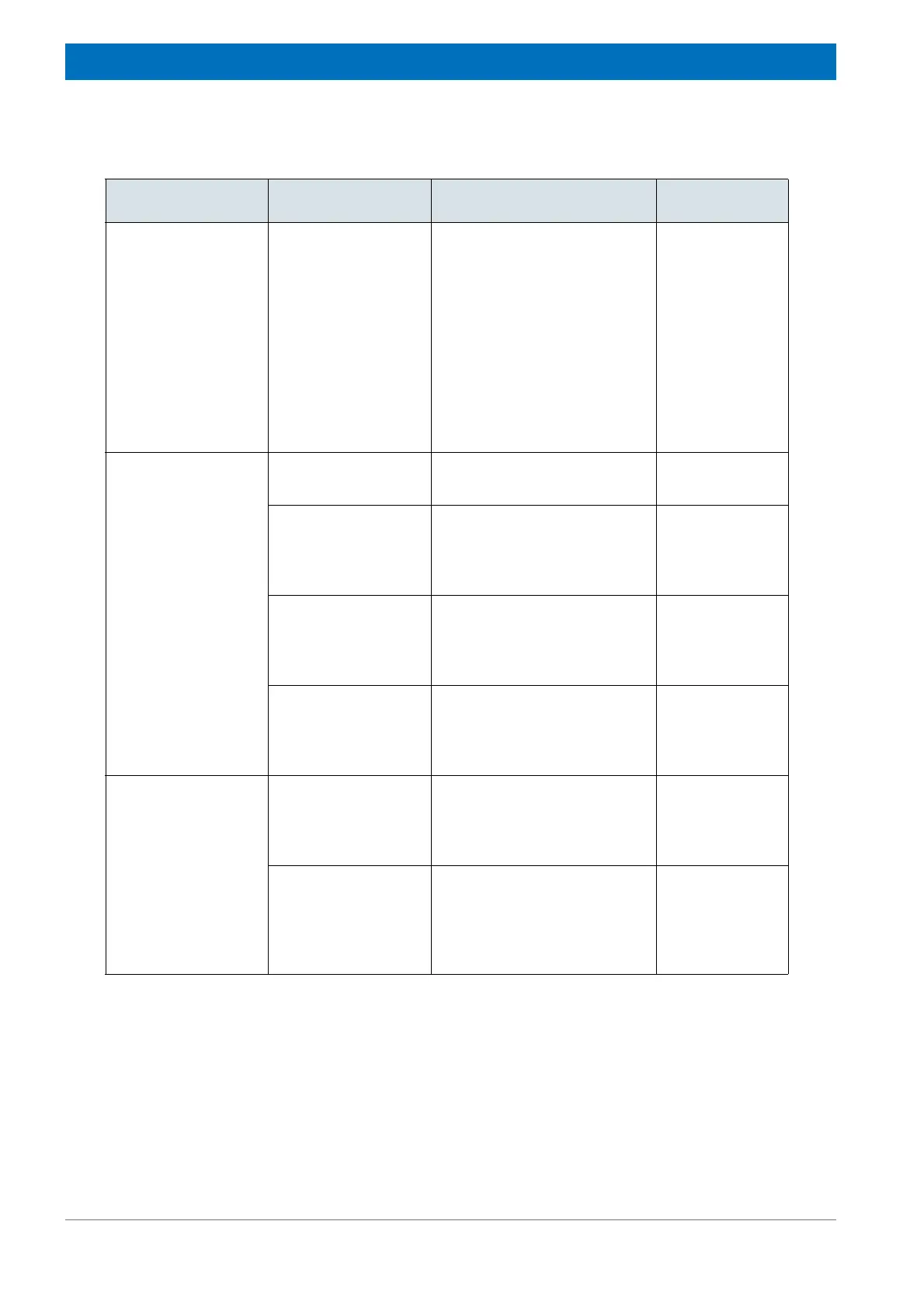

Indicator Possible reason Solution By

Nitrogen ice in the

helium vessel.

Times between

pumping and

flushing were too

long; remaining

nitrogen was boiling

off during pumping

and got frozen dur-

ing flushing.

1. Warm up the magnet coil

with warm helium gas

through the precooling

tube until the whole coil is

at 90 K or above.

2. Repeat pumping and

flushing and carefully

check with the dipstick to

be sure that the helium

vessel is completely

empty (no liquid nitrogen

or frozen nitrogen).

Bruker Service

Transfer of liquid

helium does not

start.

Empty transpor-

tation dewar .

Refill or replace transportation

dewar.

Bruker Service

The transfer

pressure in the

transportation dewar

is too low.

Increase the transfer

pressure.

Bruker Service

The transportation

dewar is leaky, no

transfer pressure

built up.

Check the transportation

dewar for leakage. Re-tighten

all connections.

Bruker Service

The siphon or the

helium transfer line

are blocked with ice.

Check the siphon and helium

transfer line for blockages,

remove ice with warm helium

gas.

Bruker Service

The cooling down of

the magnet coil does

not continue

although helium is

transferred.

The helium transfer

line is defective.

Check the helium transfer line

for icing. If there are cold

spots visible, replace the

helium transfer line.

Bruker Service

The extension piece

is not mounted on

the helium transfer

line.

Mount the extension piece on

the helium transfer line.

Check the helium transfer line

to be inserted completely into

the siphon.

Bruker Service

Loading...

Loading...