45

ZTKS0243 / Z31993 / 03

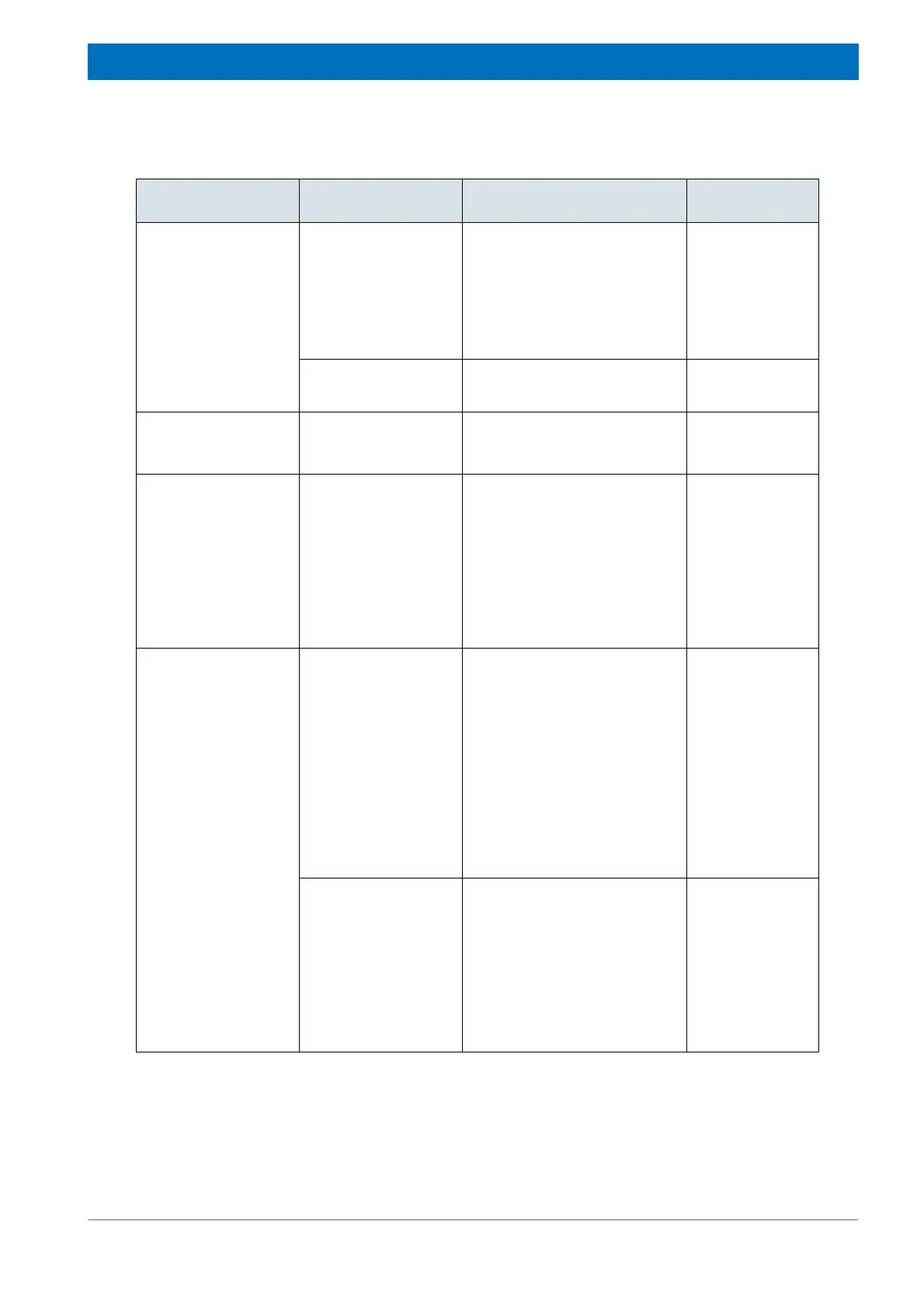

Troubleshooting

Continued from page before

Continued on next page

Indicator Possible reason Solution By

RT vessel becomes

cold and wet.

Vacuum is broken or

less than 10

-3

mbar.

• Do not remove pumping

unit until liquid helium

fill-in is finished.

• Continue as in problem

Vacuum in RT vessel

does not reach

10

-6

mbar

Bruker Service

Cold leak after

transportation.

1. Stop cool down.

2. Warm up cryostat.

Bruker Service

Cold spot in the

RT-bore.

Alignment not

correct.

1. Stop cool down.

2. Warm up cryostat.

3. Align the vessels.

Bruker Service

The helium flow

system becomes

very cold and icy

during flushing with

helium gas.

Liquid nitrogen

remains in the

helium vessel,

boiling off strongly

during flushing.

1. Stop flushing.

2. Carefully remove all

liquid nitrogen using the

precooling tube.

3. Check with the dipstick to

be sure that the helium

vessel is completely

empty (no liquid nitrogen

or frozen nitrogen).

Bruker Service

After some intervals

of flushing it is not

possible to reach a

vacuum in the range

of 1 mbar.

The globes in the

quench valves are

not fitting correctly in

the O-rings and thus

the quench valves

are leaky.

1. Stop pumping.

2. Remove frozen air and

frozen moisture with

warm helium gas.

3. Slightly grease the

O-rings and check the

position of the globes.

4. Check with the dipstick to

be sure that the helium

vessel is completely

empty (no liquid nitrogen

or frozen nitrogen).

Bruker Service

Liquid nitrogen

remains in the

helium vessel, boil-

ing off strongly dur-

ing flushing.

1. Stop pumping.

2. Carefully remove all

liquid nitrogen using the

precooling tube.

3. Check with the dipstick to

be sure that the helium

vessel is completely

empty (no liquid nitrogen

or frozen nitrogen).

Bruker Service

Loading...

Loading...