50

ZTKS0243 / Z31993 / 03

Troubleshooting

Continued from page before

6.2.5 During Operation of the Magnet Stand

In case of doubt contact Bruker Service and refer to the manual of the Magnet Stand.

Continued on next page

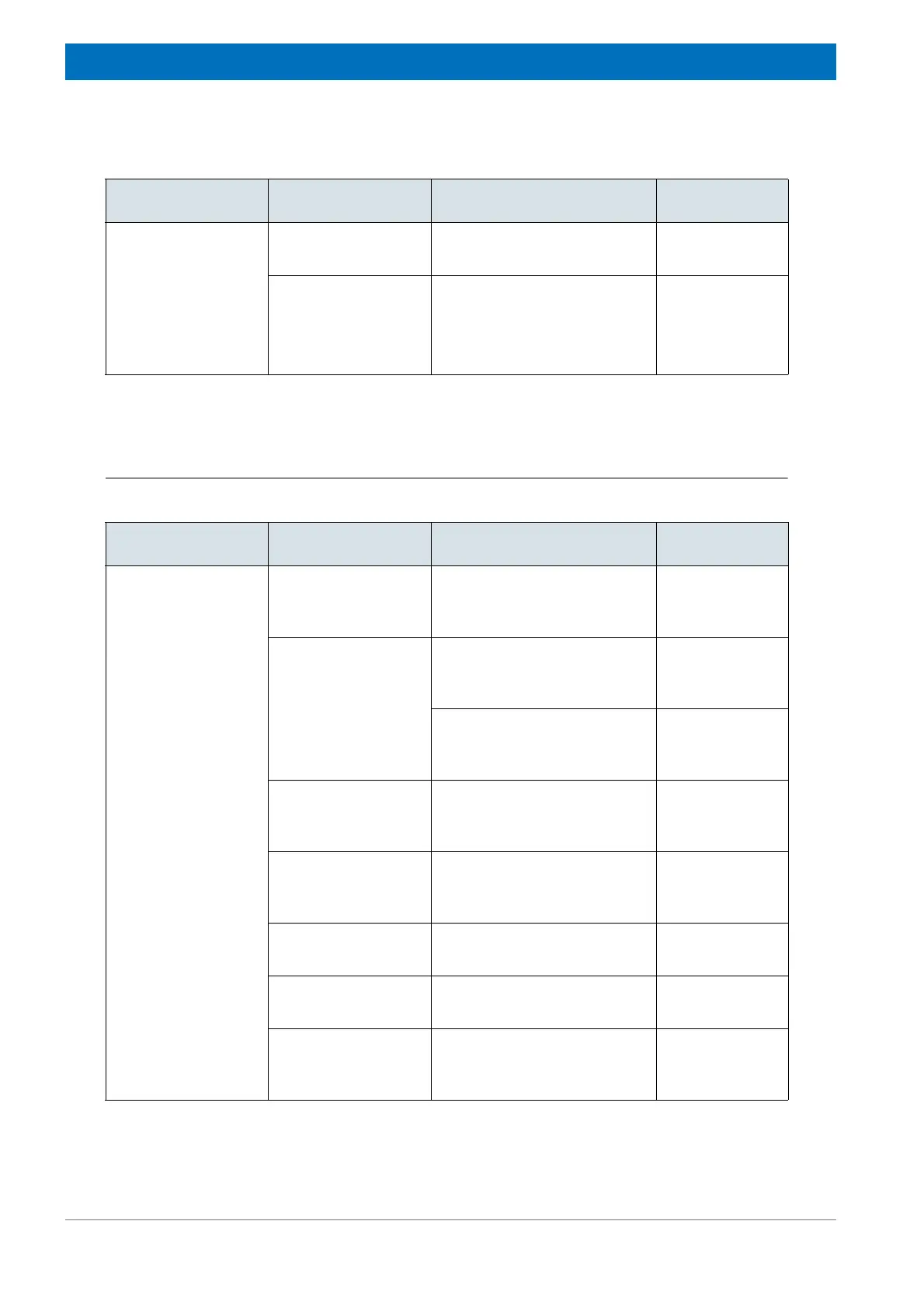

Indicator Possible reason Solution By

Magnet system does

not reach

specification.

Magnetic material

inside RT bore tube.

Carefully clean the RT bore

tube.

Bruker Service

Large ferromagnetic

parts near the

magnet system.

1. Keep the maximum pos-

sible distance between

the magnet system and

ferromagnetic parts.

2. Repeat shimming.

Bruker Service

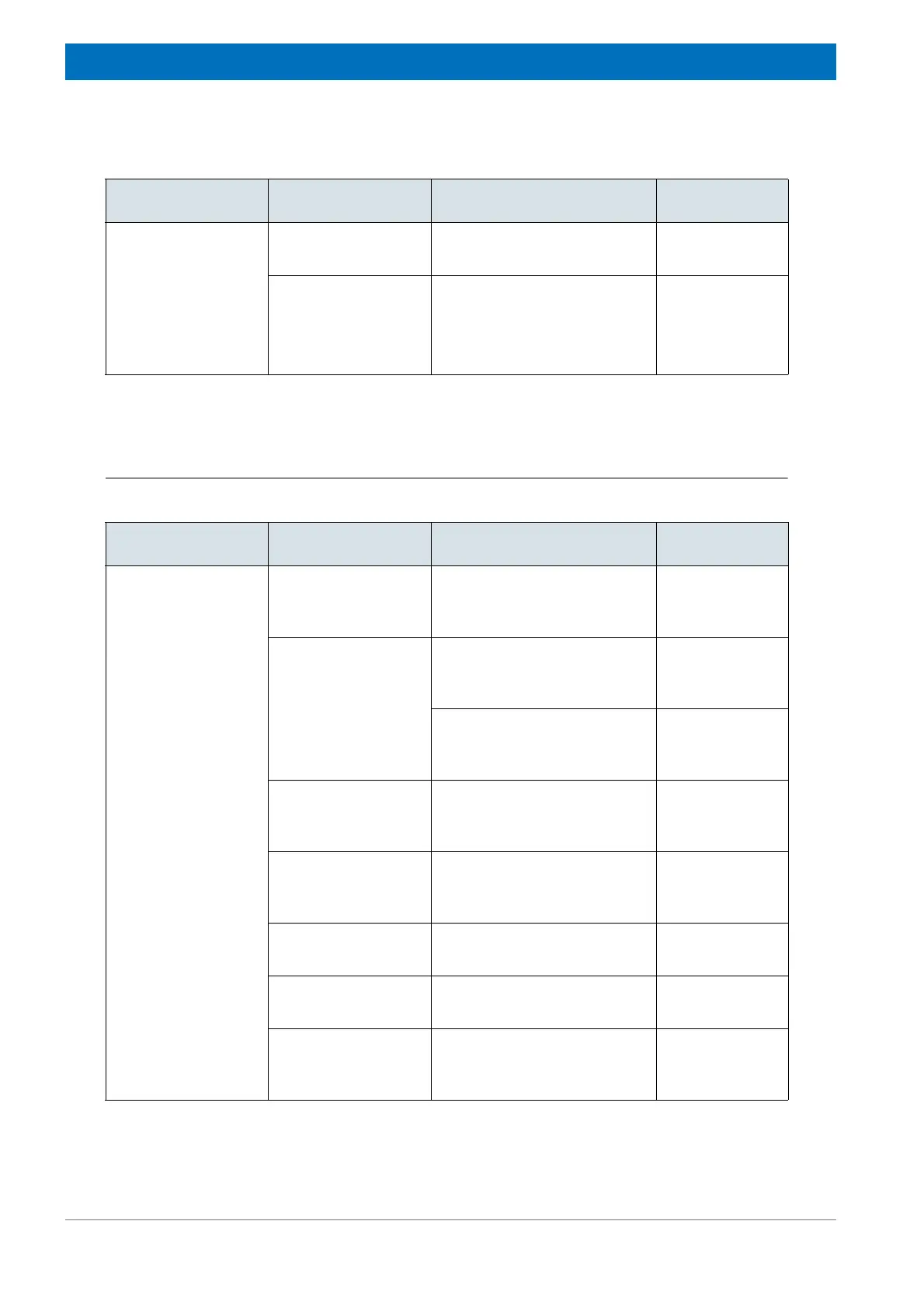

Indicator Possible reason Solution By

The NMR spectrum

shows massive

disturbances.

Pneumatic controller

is in DOWN position.

Switch pneumatic controller to

UP position.

Approved

Customer

Personnel

Magnet system has

direct mechanical

contact with the floor

via accessories or

cables.

Identify and eliminate contact

point. Arrange cables in loose

S- or U-shapes.

Approved

Customer

Personnel

If the problem is still not

solved, contact

Bruker Service.

Approved

Customer

Personnel

Magnet system has

physical contact to

the magnet stand.

Check leveling; adjust if

necessary.

Bruker Service

Piston of the isolator

is not centric or

touches its casing.

Align magnet stand. Bruker Service

T-safety bracket

touches the pillar.

Align magnet stand. Bruker Service

Floor vibrations in

vertical direction.

Replace elastomeric isolators

with air damped isolators.

Bruker Service

Floor vibrations in

horizontal and

vertical direction.

Replace air damped isolators

with air piston isolators.

Bruker Service

Loading...

Loading...