47

ZTKS0243 / Z31993 / 03

Troubleshooting

Continued from page before

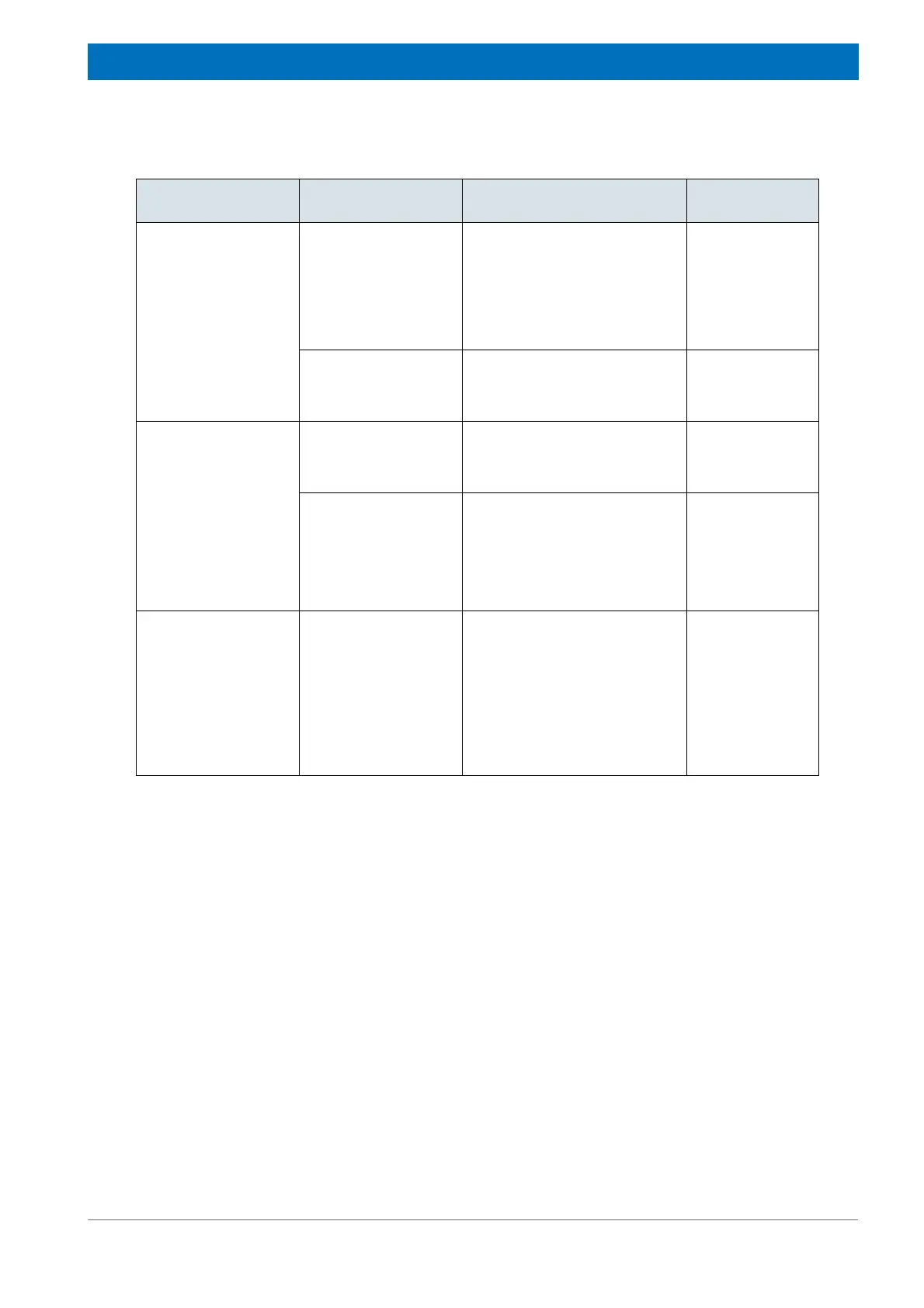

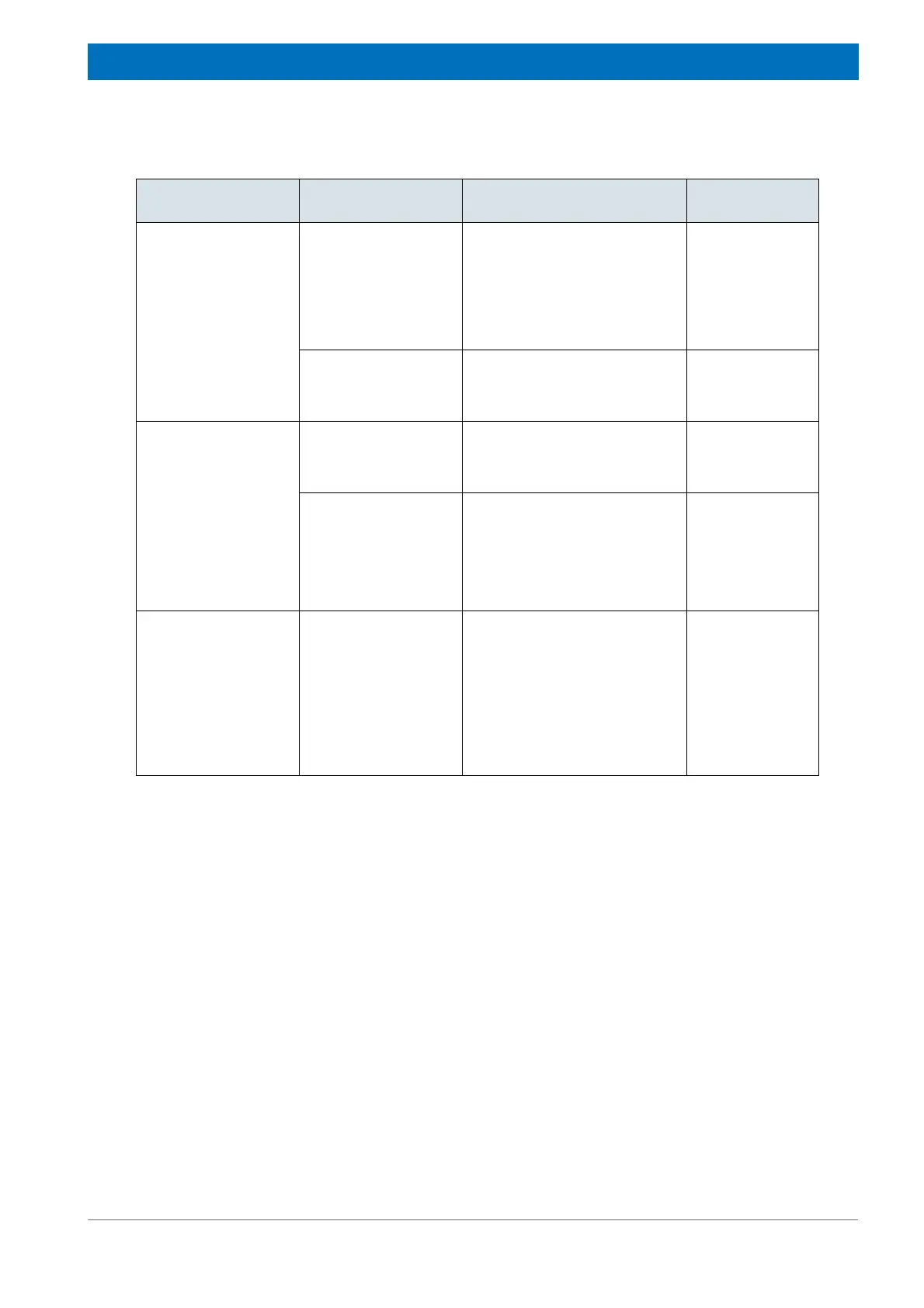

Indicator Possible reason Solution By

The zero reading of

the Helium Level

Sensor can not be

adjusted at the

beginning of cooling

down with liquid

helium.

The Helium Level

Sensor is not

connected correctly

with the connector in

the helium flow

system.

Check the connection in the

helium fill-in turret between

Helium Level Sensor and

connector.

Bruker Service

The Helium Level

Sensor is defective.

Check the Helium Level

Sensor with the

0% calibration plug.

Bruker Service

The helium level

does not reach

100% after cooling

down.

Empty transpor-

tation dewar, helium

transfer stopped.

Refill or replace transportation

dewar.

Bruker Service

The Helium Level

Sensor is disturbed

by the transfer line’s

extension piece.

1. Stop the liquid helium

transfer.

2. Remove the transfer line.

3. Measure the helium level

after some minutes

without the transfer line.

Bruker Service

After cooling down

the helium boil off is

higher than specified

(up to 5 times).

Usual behavior.

A few days are

necessary for the

radiation shields and

the insulation to

reach scheduled

temperatures.

Wait a few days and check

helium boil off.

The presence of the current

lead in the current lead turret

during energizing and

shimming helps to cool down

the radiation shield due to

higher helium flow.

Bruker Service

Loading...

Loading...