53

ZTKS0243 / Z31993 / 03

Troubleshooting

Continued from page before

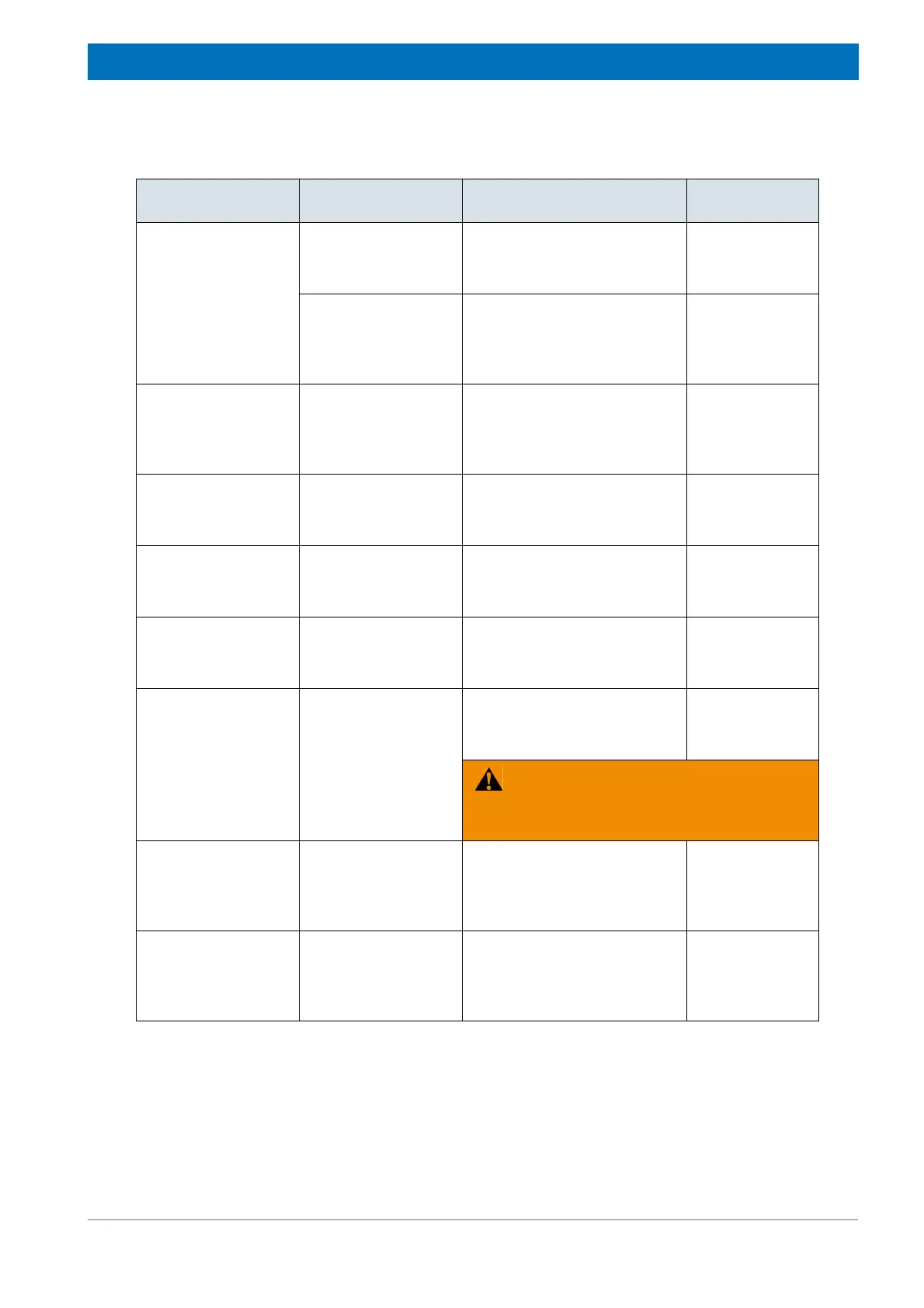

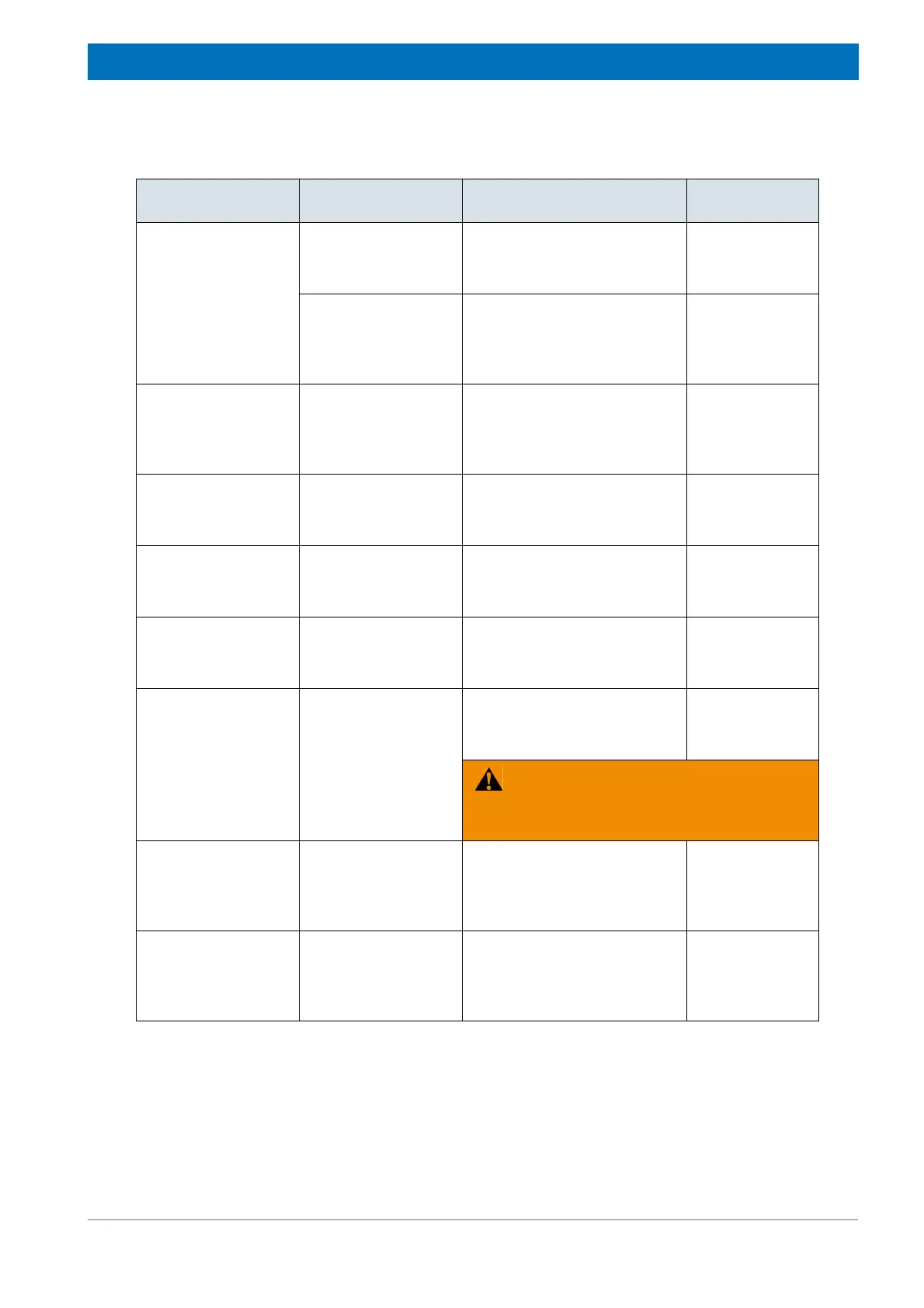

Indicator Possible reason Solution By

Continue of:

The helium boil off is

too high.

Vacuum reduced. Rebuild vacuum, see chapter

”Rebuilding Vacuum” on

page 52

Bruker Service

The radiation baffles

are not inserted in

the current lead

turret.

Insert the radiation baffles into

the current lead turret.

Bruker Service

Quench. Loss of supercon-

ductivity.

See chapter ”After a

Quench” on page 55

Contact Bruker Service

immediately!

Approved

Customer

Personnel

Cold spots within the

RT bore.

Alignment of the

vessels not correct.

Contact Bruker Service. Approved

Customer

Personnel

RT vessel is wet and

cold.

Vacuum reduced. Contact Bruker Service

immediately!

Approved

Customer

Personnel

Not correct helium

level warning out of

MICS.

Helium Level Sensor

defective.

Contact Bruker Service

immediately!

Approved

Customer

Personnel

Helium level at

constant level, no

change during days.

Helium Level Sensor

defective.

Contact Bruker Service

immediately!

Approved

Customer

Personnel

WARNING:

Low Temperature

Not correct helium

level warning out of

MICS.

Helium Level Sensor

defective.

Replace Helium Level Sensor

(see chapter ”Replacement

of the Helium Level Sensor”

on page 87)

Bruker Service

Helium level at

constant level, no

change during days.

Helium Level Sensor

defective.

Replace Helium Level Sensor

(see chapter ”Replacement

of the Helium Level Sensor”

on page 87)

Bruker Service

Loading...

Loading...