in alcoves, attics, basements, closets, crawlspaces, or utility rooms.

The design of this furnace line is not C.S.A. (A.G.A. and C.G.A.)

design-certified for installation in mobile homes, recreation ve-

hicles, or outdoors.

These instructions cover minimum requirements and conform to

existing national standards and safety codes. In some instances,

these instructions exceed certain local codes and ordinances,

especially those that may not have kept up with changing residen-

tial construction practices. We require these instructions as a

minimum for a safe installation.

CAUTION: Application of this furnace should be in-

doors with special attention given to vent sizing and

material, gas input rate, air temperature rise, and unit

sizing. Improper installation or misapplication of the

furnace can require excessive servicing or cause prema-

ture component failure.

To aid in installation, troubleshooting, and service, a status code

label is located on the blower compartment door. This label

explains how to use the LED status indicator on the furnace control

which is viewed through the sight glass on the door.

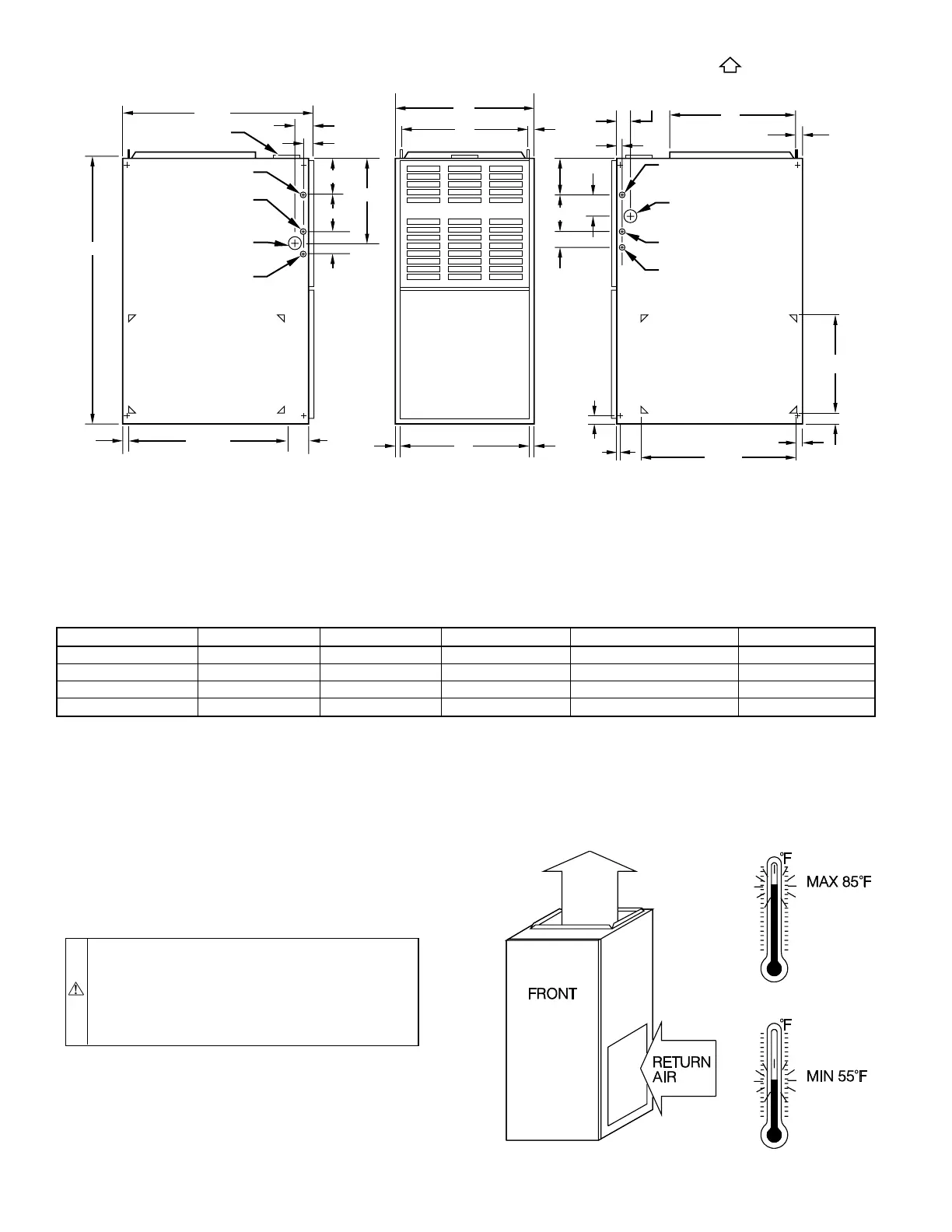

NOTE: These furnaces are designed for a minimum continuous

return-air temperature of 60°F or intermittent operation down to

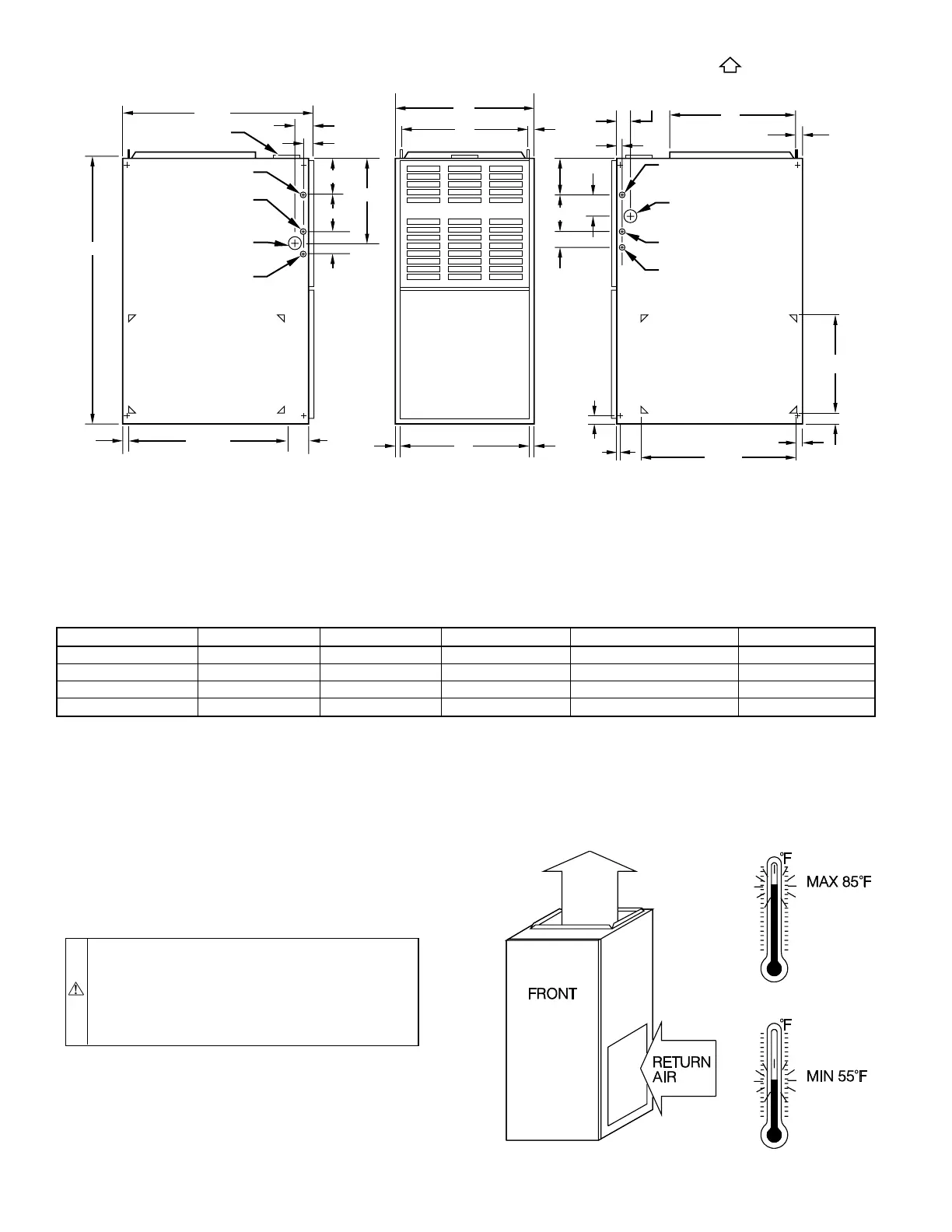

Fig. 1—Dimensional Drawing

TABLE 1—DIMENSIONS (IN.)

UNIT SIZE A D E FLUE COLLAR SHIP. WT

036060 14-3/16 12-9/16 12-11/16 4 132

048080 21 19-3/8 19-1/2 4 156

060100 14-1/2 22-7/8 12 4 183

060120 24-1/2 22-7/8 23 5 194

A00210

A

D

13

⁄16″

E

11

⁄16″

11

⁄16″

28

1

⁄2″

39

7

⁄8″

24

5

⁄16″

11

⁄16″

3″

2

1

⁄16″

1″

12

5

⁄16″

5

3

⁄8″

5

13

⁄16″

2

3

⁄8″

AIR INLET

7

⁄8-IN. DIA HOLE

POWER ENTRY

7

⁄8-IN. DIA

ACCESSORY

1

3

⁄4-IN. DIA HOLE

GAS ENTRY

1

⁄2-IN. DIA HOLE

THERMOSTAT

WIRE ENTRY

SIDE INLET

VENT CONN

1. Two additional

7

⁄8-in. dia holes are located in the top plate.

2. Minimum return-air openings at furnace, based on metal duct. If flex duct is used,

see flex duct manufacturer's recommendations for equivalent diameters.

a. For 800 CFM–16-in. round or 14

1

⁄2 x 12-in. rectangle.

b. For 1200 CFM–20-in. round or 14

1

⁄2 x 19

1

⁄2-in. rectangle.

c. For 1600 CFM–22-in. round or 14

1

⁄2 x 23

1

⁄4-in. rectangle.

d. For airflow requirements above 1800 CFM, see Air Delivery table in Product Data literature for specific

use of single side inlets. The use of both side inlets, a combination of 1 side and the bottom, or the

bottom only will ensure adequate return air openings for airflow requirements above 1800 CFM.

NOTES:

5

3

⁄8″

5

13

⁄16″

2

3

⁄8″

2

11

⁄16″

1″

2

1

⁄16″

19″

13

⁄16″

7

⁄8-IN. DIA

POWER ENTRY

AIRFLOW

OUTLET

1

1

⁄2-IN. DIA

R.H. GAS ENTRY

7

⁄8-IN. DIA ACCESSORY

1

⁄2-IN. DIA THERMOSTAT

WIRE ENTRY

SIDE INLET

14

1

⁄2″

1″

23

1

⁄4″

SIDE RETURN

DUCT LOCATION

1

1

⁄4″

TYP 1″

5

⁄8″

TYP

Fig. 2—Return-Air Temperature

A93042

—2—

Loading...

Loading...