36

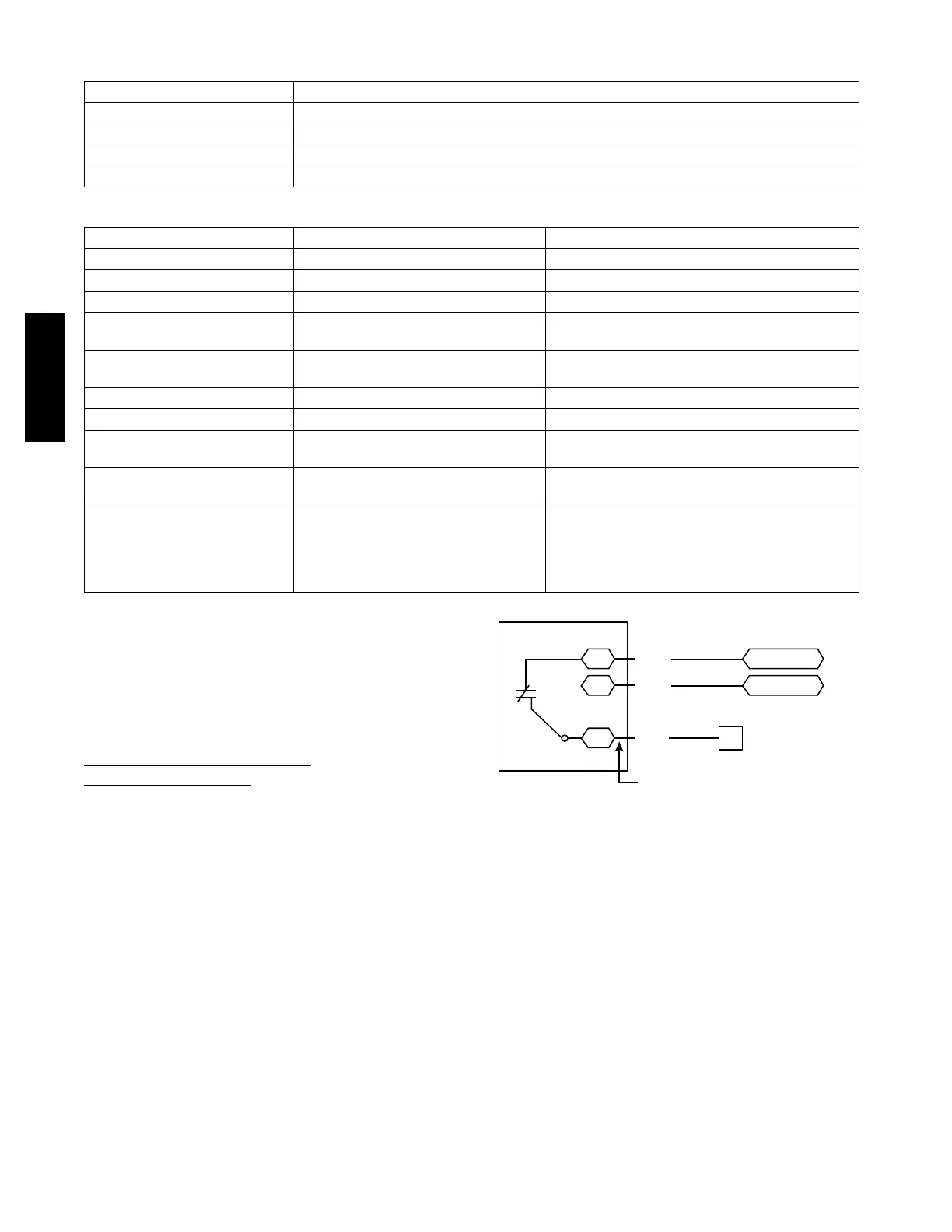

Table 7 – LEDs

The LEDs on the RTU Open show the status of cert ain functions

If this LED is on... Status is...

Power The RTU Open has power

Rx The RTU Open is receiving data from the network segment

Tx The RTU Open is transmitting data over the network segment

BO# The binary output is active

The Run and Error LEDs indicate control module and network status

If Run LED shows... And Error LED shows... Status is...

2 flashes per second Off Normal

2 flashes per second 2 flashes, alternating with Run LED Five minute auto--- restart delay after system error

2 flashes per second 3flashes,thenoff Control module has just been formatte d

2 flashes per second 4 flashes, then pause Two or more devices on this network have the

same MSTP network address

2 flashes per second On Exec halted after frequent system errors or

control programs halted

5 flashes per second On Exec start ---up aborted, Boot is running

5 flashes per second Off Firmware transfer in progress, Boot is running

7 flashes per second 7 flashes per second, alternating with

Run LED

Ten second recovery period after brownout

14 flashes per second 14 flashes per seco nd,

alternating with Run LED

Brownout

On On Failure. Try the following solutions:

S Turn the RTU Open off, then on.

S Format the RTU Open.

S Download memory to the RTU Open.

S Replace the RTU Open.

NOTE: Refer to the RTU Open multi--pr oto col contr oller

Controls, Start--Up, Operation and Troubleshooting manual

for complete configuration of RTU Open, operating

sequences and troubleshooting information. Contact your

Bryant applications engineer for details on confi guration

and troubleshooting of connec ted networks.

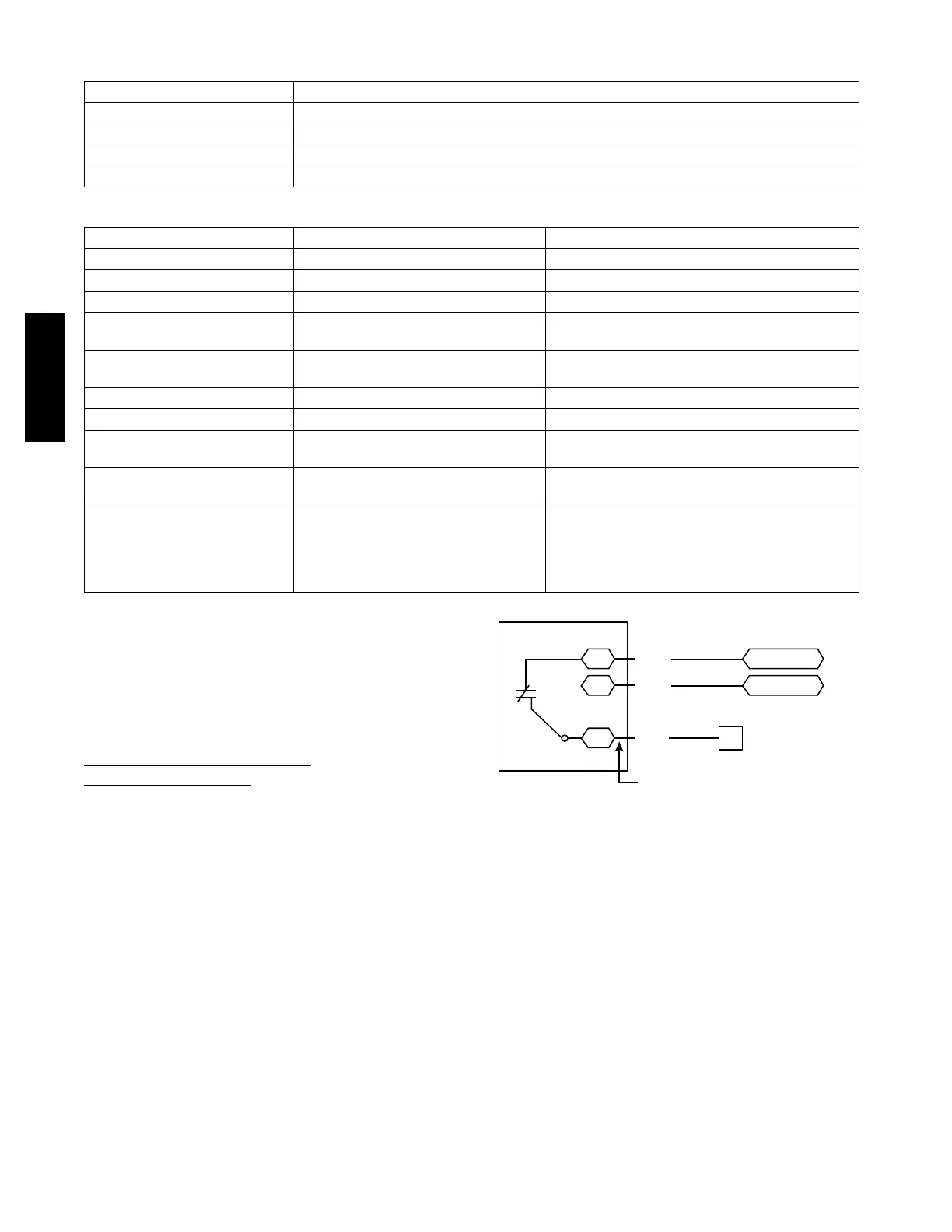

Outdoor Air Enthalpy Control

(PNO

33CSENTHSW)

The enthalpy control (33CSENTHSW) is available as a

field--installed access o ry to be used with the EconoMi$er

R

2

damper system. The outdoor air enthalpy sensor is part of

the enthalp y control. (The s ep arate field--installed acces s o ry

return air enthalpy sensor (33CSENTSEN) is required for

differential enthalpy control. See Fig. 57.)

Locate the enthalpy control in the economizer next to the

Actuato r Motor. Locate two GRA leads in the facto ry

harness and connect the gray lead labeled “ESL” to the

terminal labeled “LOW”. See Fig. 57. Co nn ect the enthalpy

control power input terminals to economizer actuator power

leads RED (connect to 24V) and BLK (connect to GND).

7

CTB ECON

(P’LINK: to J4-2) or

(RTU Open: to J2-6)

LOW

GND

24V

Enthalpy

Switch

GRA

BLK

RED

Factory Wiring Harness

PL6-1 (24-V)

PL6-4 (COM)

C11160

Fig. 57 -- Enthalpy Switch (33CSENTHSW) Connections

The out door enthalpy changeover setpoi nt is set at the

enthalpy controller.

Differential Enthalpy Control —

Differential enthalpy control is provided by sensing and

comparing the outside ai r and return air enthalpy

conditions. Install the outdoor air enthalpy c ontrol as

described above. Add and install a return air enthalpy

sensor.

582J

Loading...

Loading...