6

Installation

Logamax plus GB162- 80/100 kW - Subject to modifications resulting from technical improvements!

25

Do not exceed the total equivalent venting length of 100

feet (30,480 mm) maximum requirement each for the

intake and exhaust piping.

Æ table 8 for the Friction Loss Equivalent in piping and

fittings.

Example:

When you end up using 3 x 45° -elbows and the concen-

tric roof terminal, then the total venting length may not

exceed 68 ft. (20.72 m).

3×45°-elbow = 3 x 4ft. (1.22m) = 12ft. (3.66m)

concentric roof terminal 4"/6" = 20 ft. (6.10 m)

Total friction loss equivalent = 32 ft. (9.76 m)

Total venting length for this example is:

GB162-80 kW/100kW = 100 ft. (30.48 m) - 32 ft. (9.76

m) = 68 ft. (20.72 m) each for the intake and exhaust

piping.

At the time of removal of an existing boiler, the following

steps shall be followed with each appliance remaining

connected to the common venting system placed in

operation, while the other appliances remaining

connected to the common venting system are not in

operation:

a) Seal any unused openings in the common venting

system.

b) Visually inspect the venting system for proper size and

horizontal pitch and determine there is no restriction,

leakage, corrosion and other deficiencies which could

cause unsafe condition.

c) Place in operation the appliance being inspected.

Follow the lighting instructions. Adjust thermostat so

appliance will operate continuously.

d) Test for spillage at the draft hood relief opening after 5

minutes of burner operation. Use the flame of a match or

candle, or smoke from a cigarette, cigar or pipe.

e) Any improper operation of the common venting system

should be corrected so the installation conforms with the

National Fuel Gas Code, ANSI Z223.1/NFPA 54 and/or

CAN/CSA B149.1, Natural Gas and Propane Installation

Code.

When resizing any portion of the common venting system,

the common venting system should be resized to

approach the minimum size as determined using the

appropriate tables in Part 11 of the National Fuel Gas

Code, ANSI Z223.1/NFPA 54 and/or CAN/CSA B149.1,

Natural Gas and Propane Installation Code.

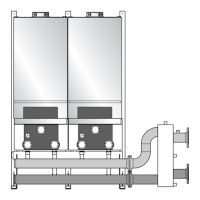

6.9 Multiple boiler vent terminal

clearance

Vertical terminations:

The combustion air inlet pipe must terminate in a down-

ward position using 2 × 90° elbows. The combustion air

inlet pipe shall terminate at least 3 ft (914 mm). horizon-

tally from the center line of the exhaust vent, this is to

prevent cross contamination of flue gases into the

combustion air stream.

Terminate all exhaust vents at the same height and all

combustion air inlets at the same height, while maintaining

the minimum 36" (914 mm) height clearance from the

exhaust to the down turned 90° elbow and combustion air

inlet.

Exhaust vent termination edge shall be at least

24" (610 mm) from the edge of the air inlet pipe of an

adjacent heater. Exhaust vent terminations shall be placed

at a minimum of 12" (305 mm) center to center.

(Æ fig. 30 & fig. 31) Air intake terminations may be

placed adjacent to each other. The combustion air inlet is

part of the direct vent system and not classified as a

forced air inlet.

NOTICE

B Appliance input rates are based on

minimum vent length operation. Longer

vent lengths (up to maximum) will

reduce the input proportionally.

Fittings or Piping

Equivalent

feet m

45° elbow 4 1.22

90° elbow 7 2.13

plastic pipe per foot 1 0.30

parrallel vent kit 2 0.61

concentric roof terminal

4"/6" (100/150 mm)

20 6.10

Tab. 8 Friction Loss Equivalent in piping and fittings

NOTICE

B The minimum covering wall thickness is

1" (25.4 mm). The maximum covering

wall thickness is 16" (406 mm).

B For direct venting properly reassemble

and reseal the vent and air-intake

systems.

CAUTION:

B Vent connectors serving appliances

vented by natural draft shall not be

connected into any portion of

mechanical draft systems operating

under positive pressure.

Loading...

Loading...