10

Mounting the burner

Logano G515 – 6 720 647 208 (2014/09)34

10 Mounting the burner

This chapter explains the basic steps involved in fitting a burner

▶ Close the burner door and seal with 4 machine screws (M16 × 140)

( Chapter 7.8.3, page 21, Fig. 32, [3 to 6]). Tighten the machine

screws evenly crosswise.

If you have ordered an undrilled burner plate, you will have to machine

the plate on site:

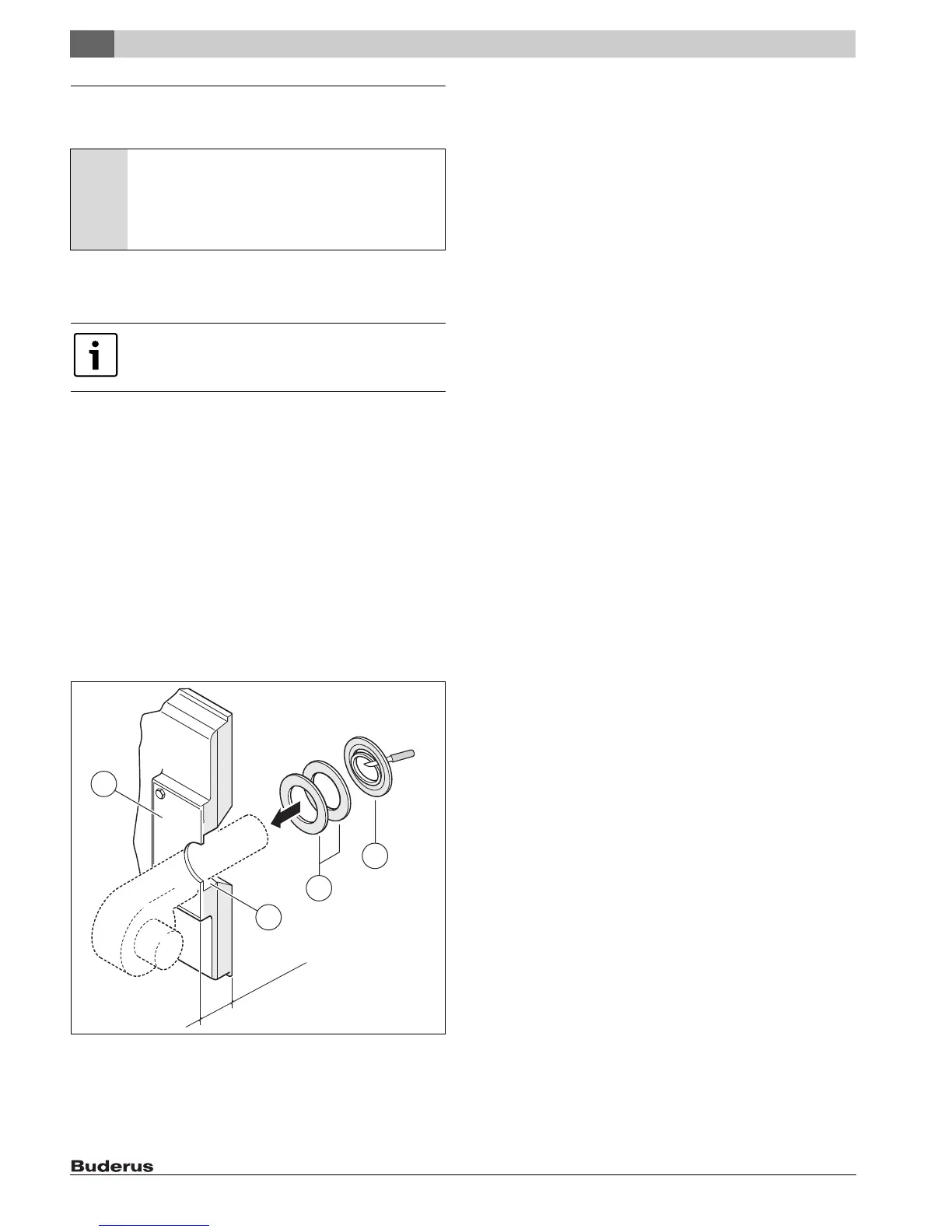

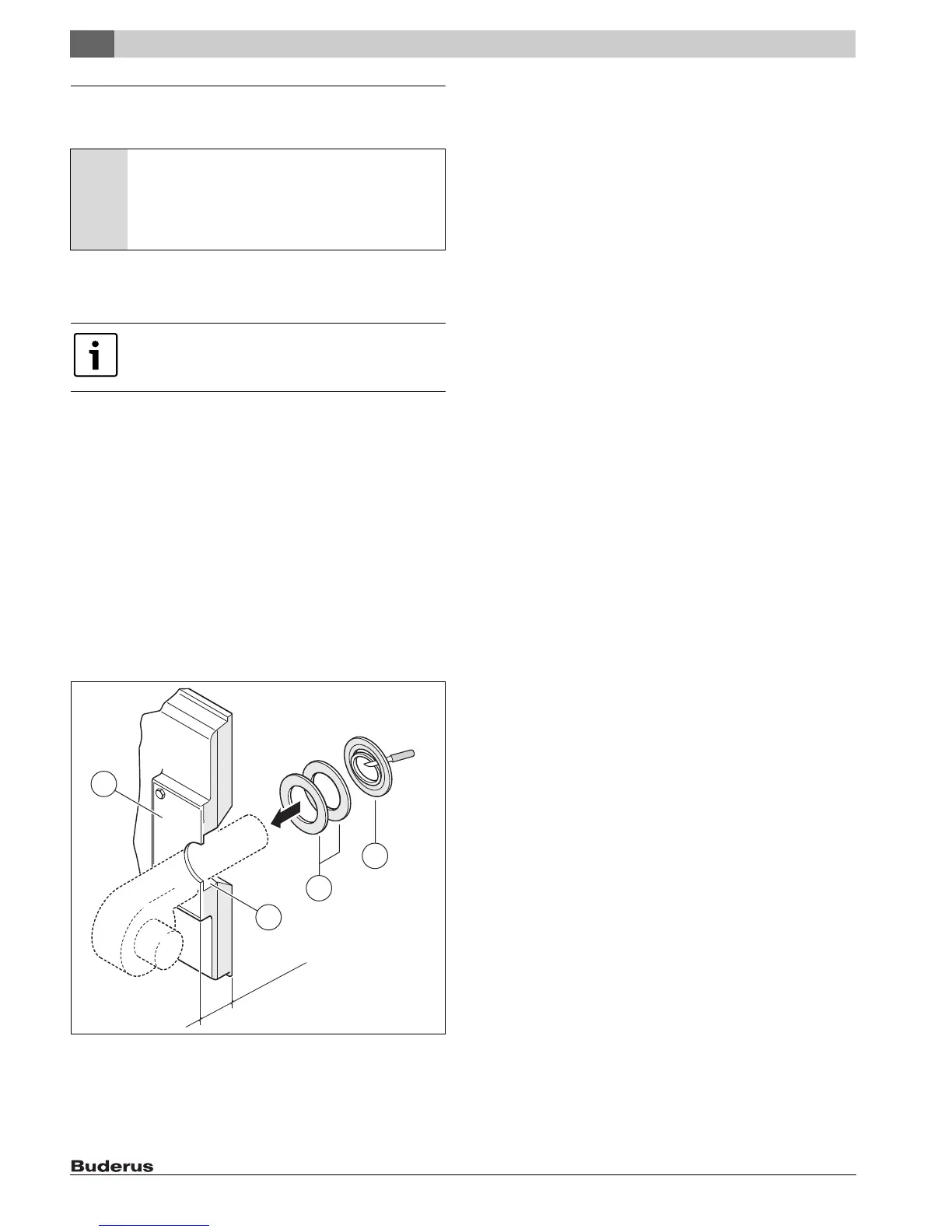

▶ Drill or cut the burner plate ( Fig. 66, [1]) to match the required

burner tube diameter Ø 10 – 5/8 inches (270 mm).

▶ Drill burner attachment holes using the burner flange as a template.

▶ Screw burner plate onto the burner door (seal with GP sealant rope;

diameter Ø 25/64 inches (10 mm)).

▶ Screw the burner to the burner plate.

▶ Cut out insulating rings to match the burner tube diameter

( Fig. 66, [2]).

▶ Fill the remaining gap between the burner door thermal insulation

and the burner tube Fig. 66, [4]) using the appropriate insulating

rings ( Fig. 66, [3]).

▶ Connect the vent connection to the burner to ensure the inspection

window remains free of deposits.

Fig. 66 Mounting the burner

NOTICE: Risk of system damage from use of incorrect

burner.

▶ Only use burners that meet the technical

requirements of the oil/gas-fired boiler Logano

G515 ( Chapter 3, page 8).

You can obtain undrilled or predrilled burner plates (hole

pattern depends on burner) as accessories from

Buderus.

6 720 642 623-63.1o

2

3

4

1

(145 mm)

5 45/64"

Loading...

Loading...