english

Operating Instructions-No. 803 150

13

3 GENERAL DESCRIPTION

3.1 Valve Construction

• 3/2 way pilot valve with various electrical connection possibilities

• the top-mounted coil can be locked in 4 x 90° steps, for optional positioning in between

around the core guide tube

• valve body with diaphragm and seat seals (3/2 and 5/2), or with gate valve (5/3)

• working connections 2 (B) / 4 (A) and supply and ventilation connections 1 (P) / 3 (S) /

5 (R) with G 1/4 internal thread or plug connection for 8 mm hose external diameter

• the valves can be mounted on the modular pneumatic basic rail Type MP07

• can be mounted in any position, preferably with the magnetic system at the top

the valves are also available in explosion-proof versions

3.2 Valve operations of the Type 6518 / 6519

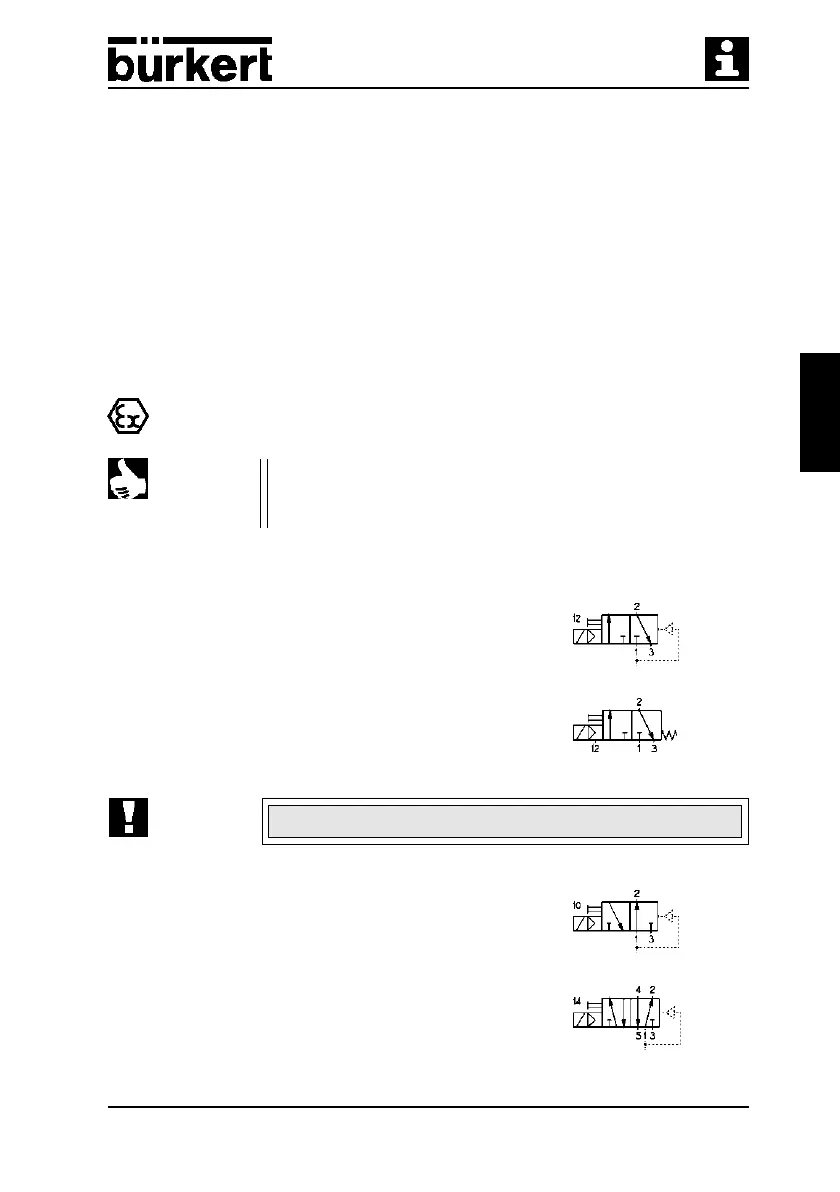

3/2 way valve:

In de-energised position, Pressure Inlet 1 closed,

Outlet Port 2 exhausted

3/2 way valve for vacuum, with auxiliary pilot air:

In de-energised position, Pressure Inlet 1 closed,

Outlet Port 2 exhausted

The vacuum generator must be connected to port 1!

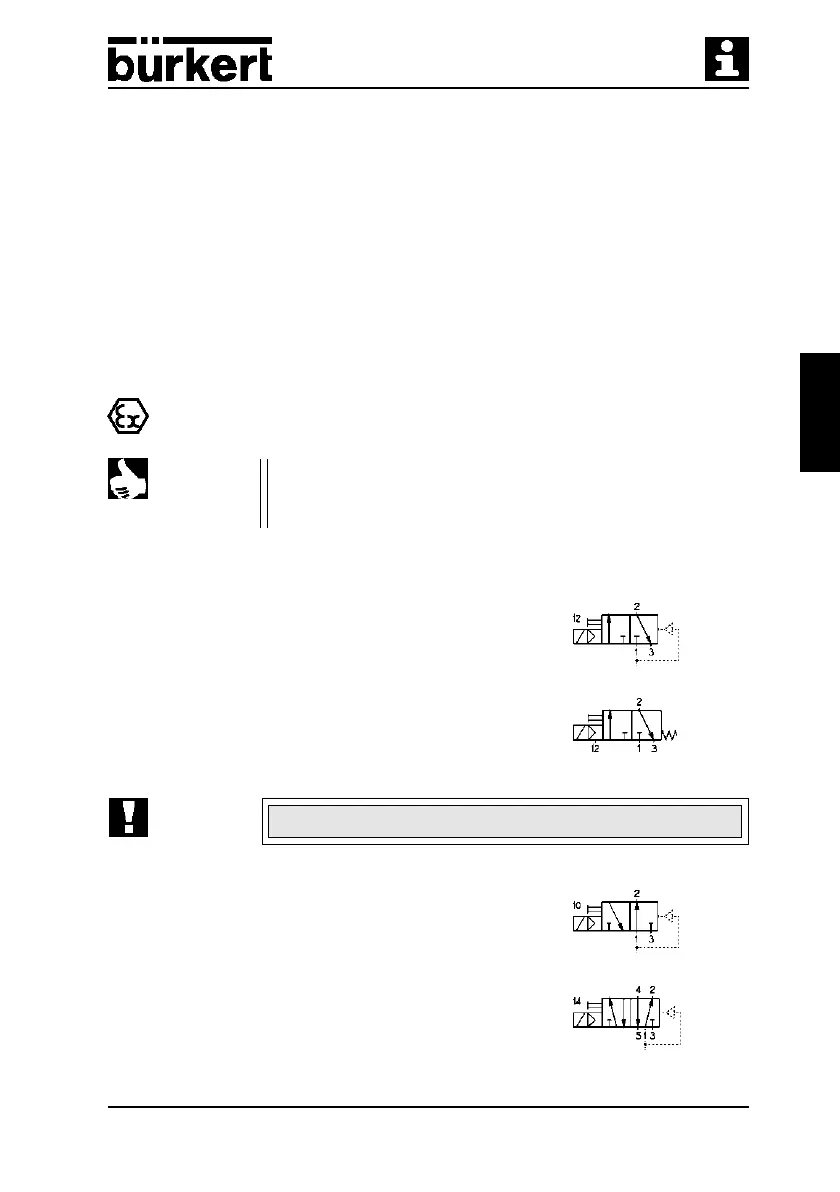

3/2 way valve:

In de-energised position, Pressure Inlet 1 connected

to Outlet Port 2

5/2 way valve:

In de-energised position, Pressure Inlet 1 connected

to Outlet Port 2, Outlet Port 4 exhausted.

ATTENTION!

NOTE Plug-in connections only for the service ports 2 (B) and 4 (A).

The valves require no maintenance.

Loading...

Loading...