27

Installation and commissioning

Type 8710, 8711, 8713, 8715

7.6. Mechanical installation

Observe the mounting position shown on the calibration plate or the

calibration protocol.

7.7. Fluid installation

danger

Risk of injury due to high pressure in the installation.

• Stop the circulation of fluid, cut off the pressure and drain the

pipe before loosening the process connections.

Select the fluid connections suitable for the maximum flow-rate. There

is no minimum upstream distance to be observed.

On request, the device may be supplied with the fluid connections fitted.

Warning

Danger from leaks

If flow-rates are low and pressures high, ensure that the system

is sealed to prevent incorrect metering or the operating fluid from

leaking.

• To ensure that the seal is secure, observe the operations

described below.

Install the fittings without subjecting them to any stresses. To seal the

system properly, use fittings with olives.

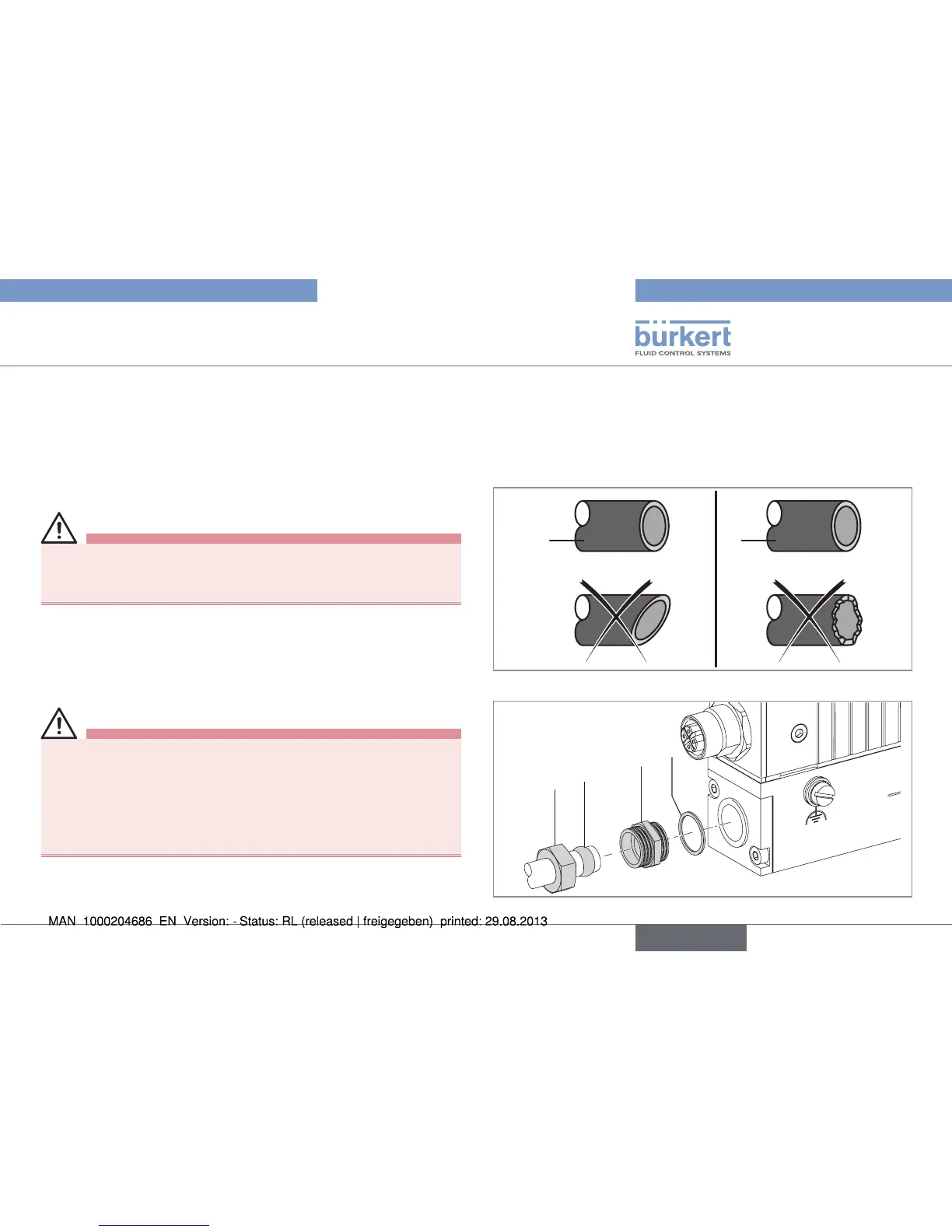

Use a line with a suitable diameter and a smooth surface.

→ Cut the line squarely [1] and deburr [2].

1 2

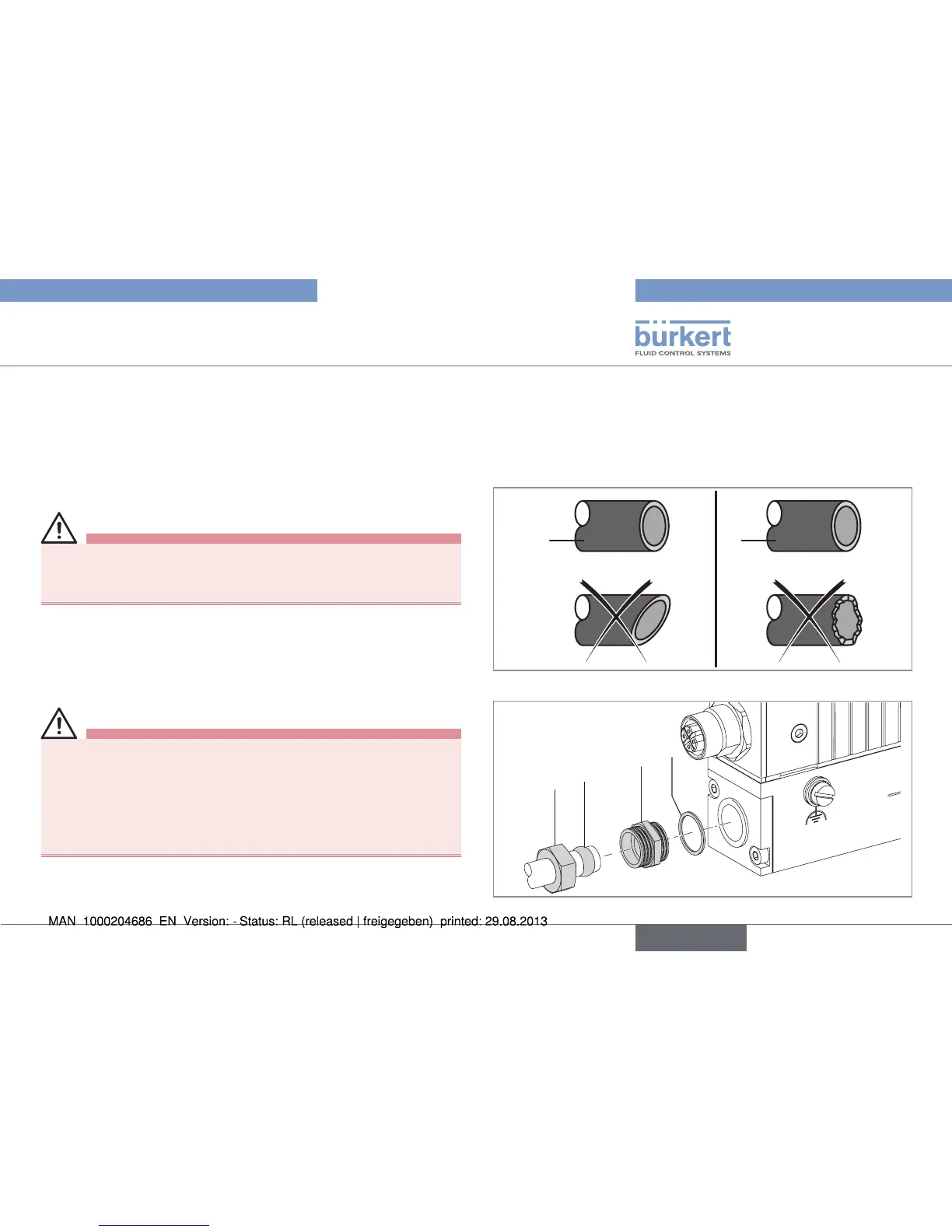

→ In order, fit the nut [A] and the olive onto the line.

A

Olive

B

C

English

Loading...

Loading...