40

Maintenance, Troubleshooting

Type 8700, 8701, 8703, 8705

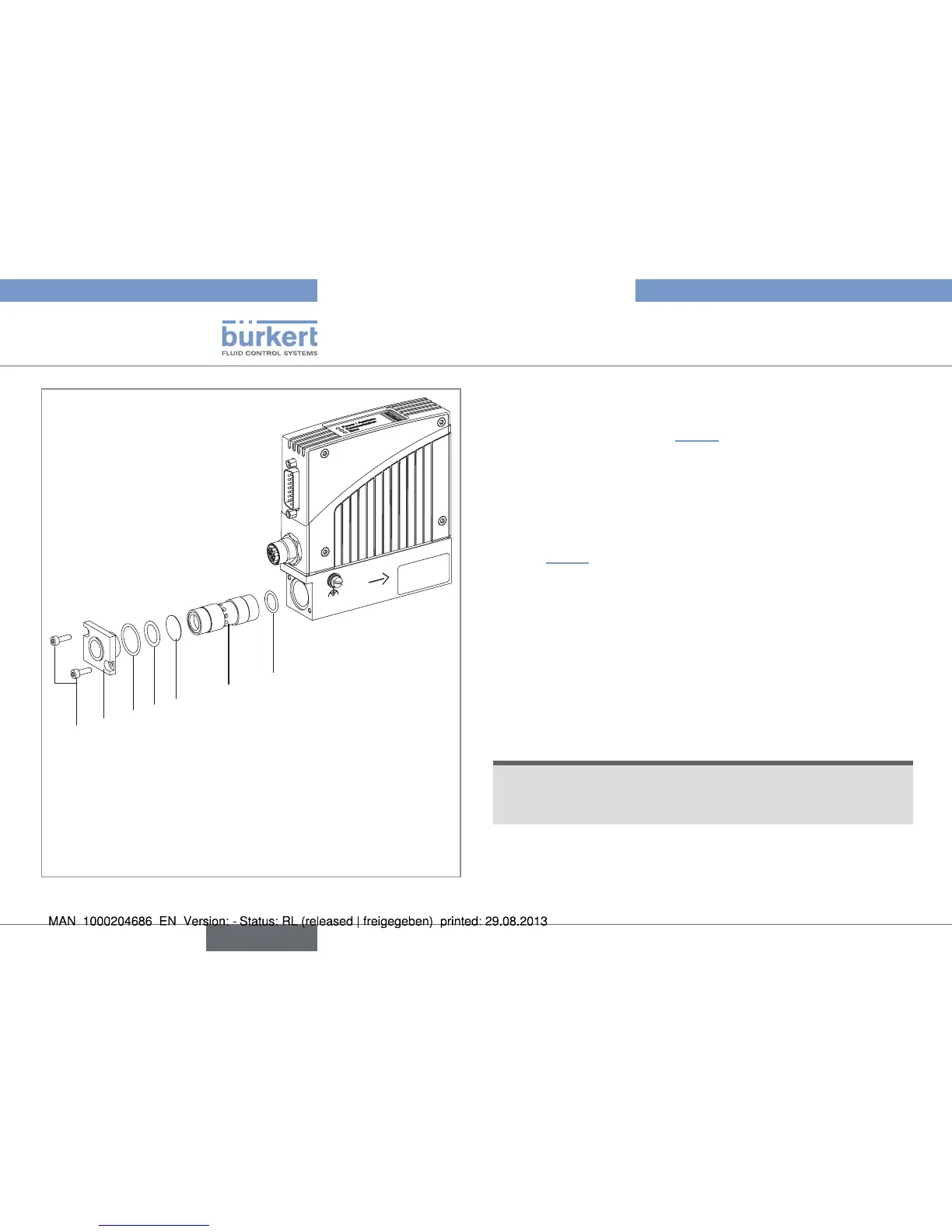

4

5

7

3

2

1

6

1 - Screws

2 - Inlet flange plate

3 - O-ring

4 - O-ring

5 - Stainless steel mesh filter

6 - Orifice tube

7 - O-ring

Fig. 20: Maintenance, Cleaning

Procedure:

→ To gain access to the stainless steel mesh filter disc, detach the

input flange plate [2] (see Fig. 20).

→ Take out the stainless steel mesh filter disc.

→ Clean the stainless steel mesh filter disc [5] using distilled water

(not tap water), acetone, isopropanol or compressed air.

→ Dry the parts after cleaning.

→ Re-insert parts in the correct sequence and position

(see Fig. 20). The fine mesh of the filter disc [5] must face

the input flange plate [2].

9.2.2. Cleaning and recalibration at the

factory

If the sensor is excessively soiled or damaged by the operating gas, the

device may deviate significantly from the mass flow-rate measurement.

Cleaning or replacement followed by recalibration at the factory will

then be required.

note

• Recalibration must be carried out at the factory as it requires

the use of very precise references and a specific digital

communication system.

English

Loading...

Loading...