25

q. After all sections have been drawn up, the

draw-up rod nuts should be loosened until

nger tight and then tightened ½ turn with

a wrench.

C. HYDROSTATIC TEST — After the boiler sections

have been assembled, it is essential that the boiler be

hydrostatically tested before the canopy, ue cover

plates, jacket, or piping is installed.

1. Tankless Heater Installation

If boiler is ordered with tankless heaters, install

heaters with the gaskets provided. Table IX gives

the maximum number of heaters permissible per

assembly and the heater ratings.

2. Plug all boiler tappings and ll boiler completely

with cold water. Allow cold ll water to reach room

temperatue before sealing boiler and pressurizing.

DO NOT install gauge until after hydrostatic testing the

boiler. Gauge failure may result.

N’installez la jauge qu’après avoir testé hydrostatique la

chaudière. Une défaillance de la jauge peut en résulter.

3. All completed boilers must satisfactorily pass the

prescribed hydrostatic test.

a. HOT WATER BOILERS: The assembled boiler

must be subjected to a hydrostatic test of not less

than 1½ times the maximum allowable working

pressure, as established by the relief valve

provided with the boiler. For example, a boiler

with a 50 psi relief valve must be subjected to a

test pressure of 75 psig to 85 psig.

Failure to properly hydrotest all boilers at the correct

pressure may result in section assembly failure in

operation.

Le fait de ne pas hydrotester correctement toutes les

chaudières à la pression correcte peut entraîner une

défaillance de l’assemblage de la section en cours de

fonctionnement.

4. EXAMINE BOILER CAREFULLY, INSIDE AND

OUTSIDE, to insure against leaks from cocked

nipples or through concealed breakage caused in

shipping and handling. This precaution is for your

protection and will simplify handling of necessary

replacements and adjustment claims.

5. After making certain that there are no leaks, drain

boiler and remove plugs for boiler trim and other

connections.

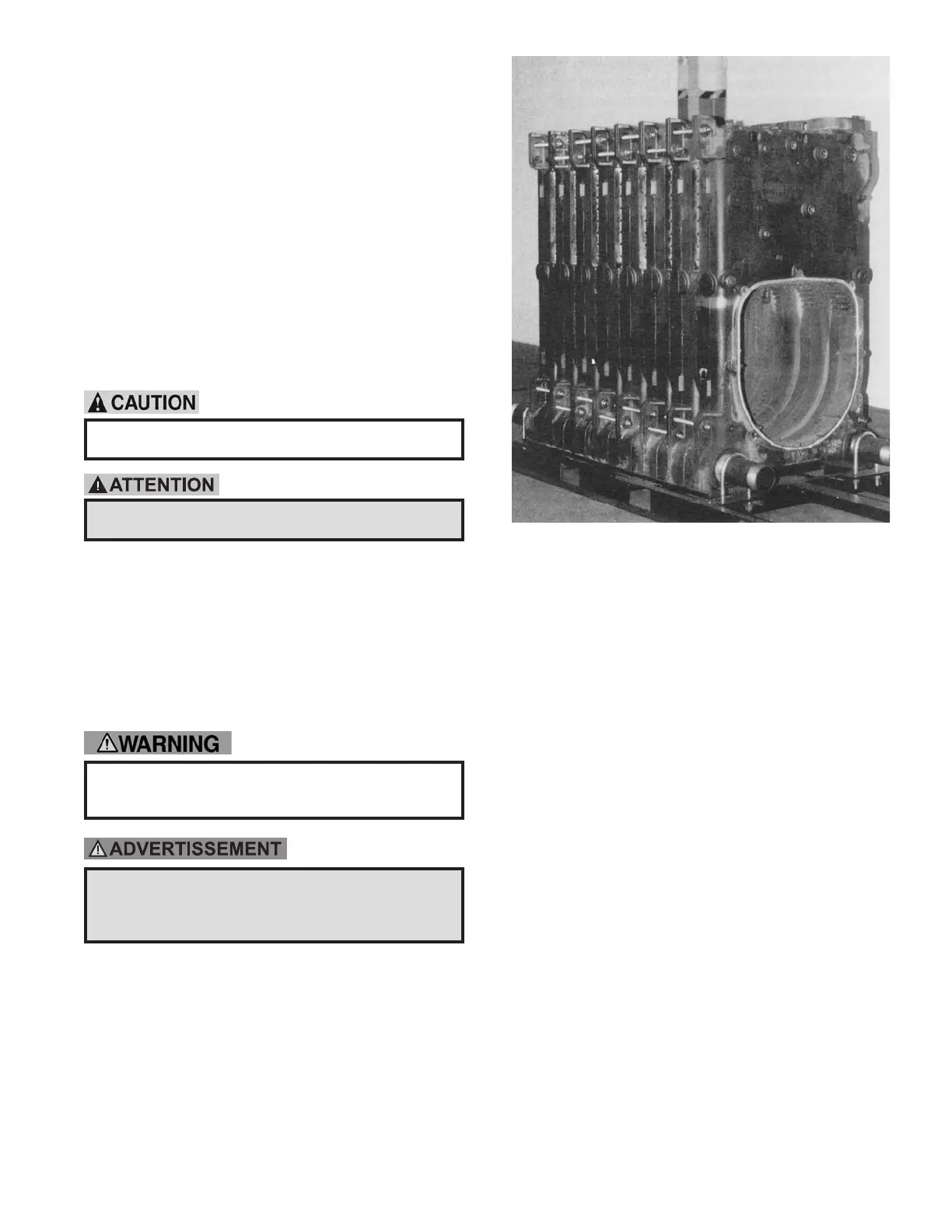

Figure 10: Boiler Section Assembly

Loading...

Loading...