33

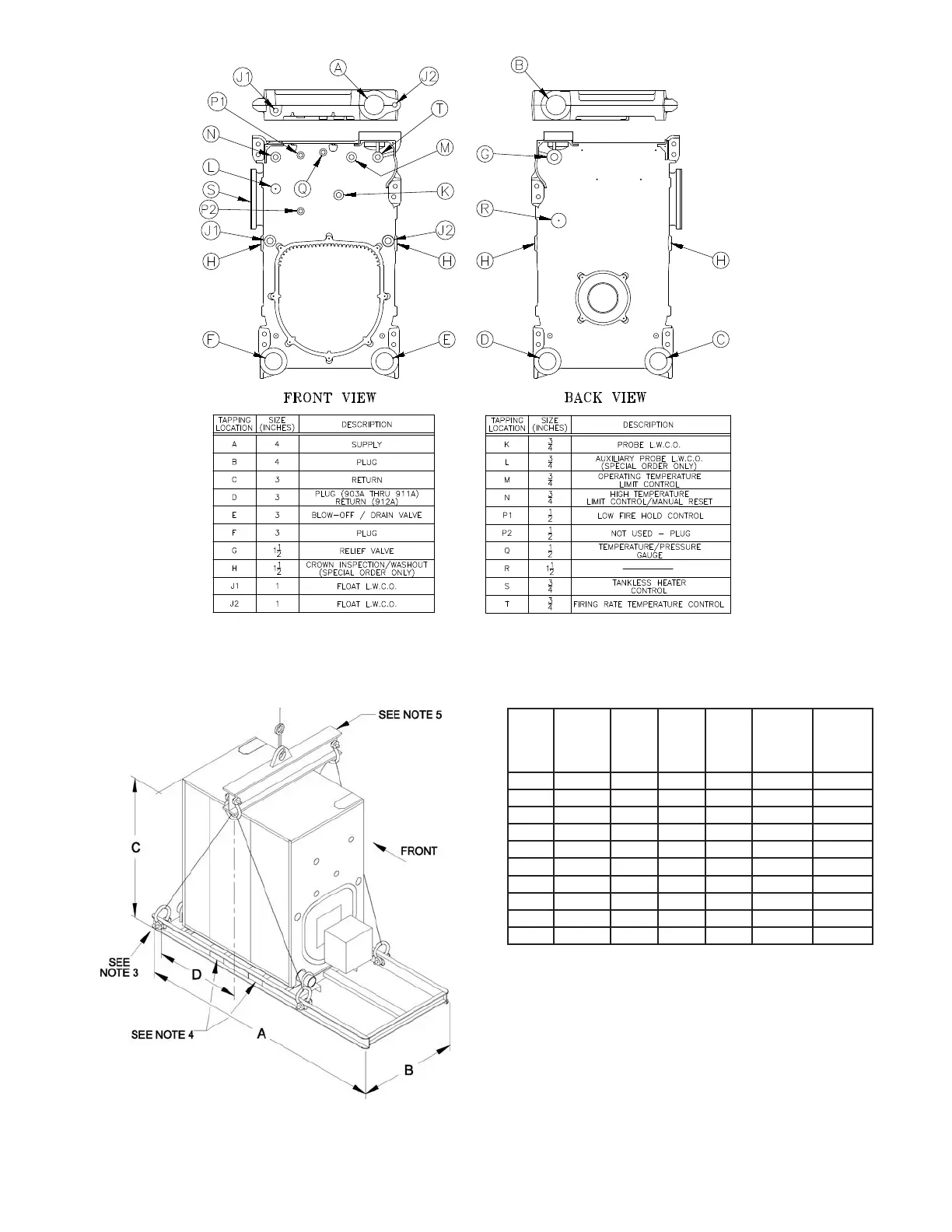

Figure 21: Purpose of Tappings

Boiler

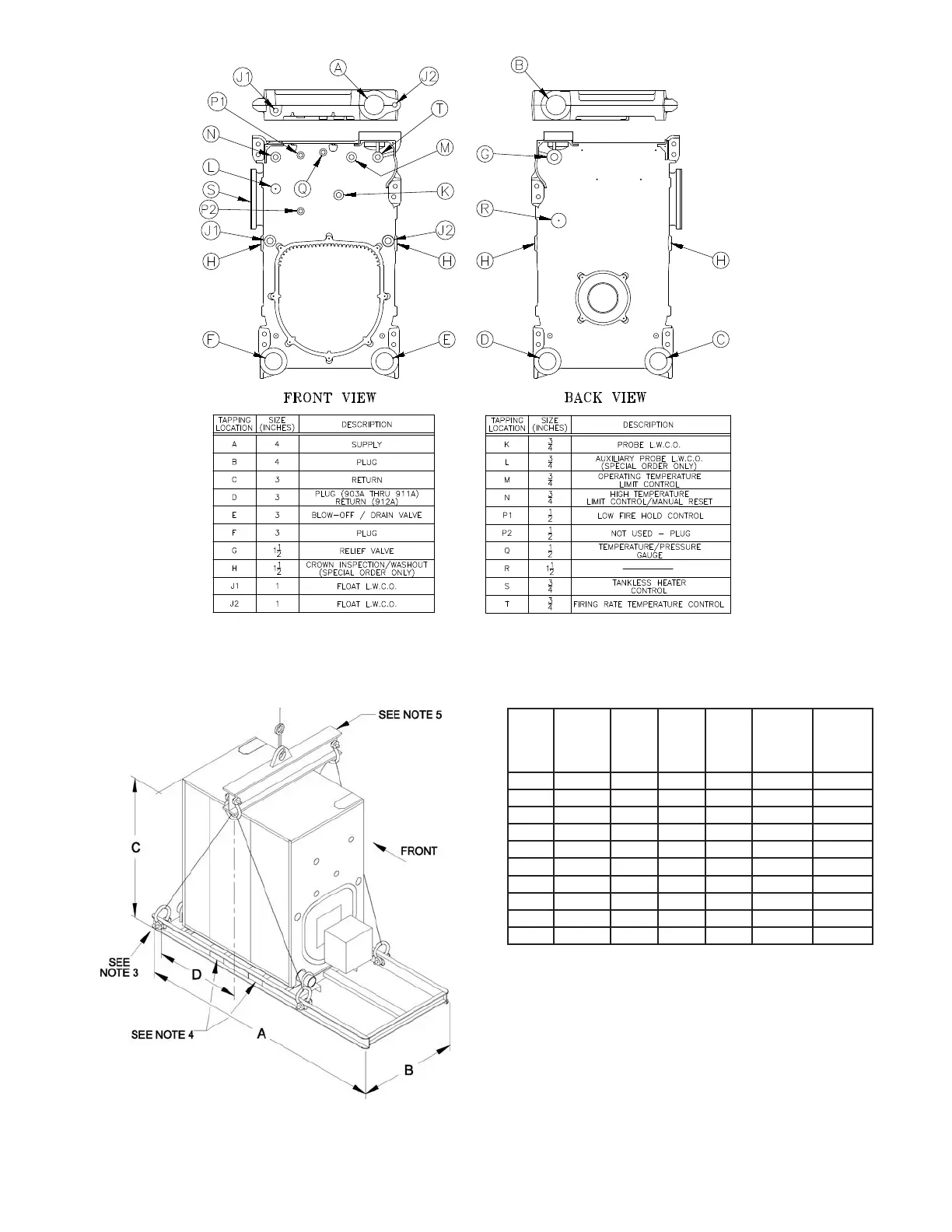

Model

Number

of

Sections

Length

A

Width

B*

Height

C**

Approx.

Center of

Gravity

D***

Approx.

Shipping

Weight

LBS***

V903A 3 63-5/8 34-1/2 61 17-1/2 1478

V904A 4 69-5/8 34-1/2 61 20-1/2 1790

V905A 5 75-5/8 34-1/2 61 23-1/2 2102

V906A 6 81-5/8 34-1/2 61 27-1/2 2418

V907A 7 87-5/8 34-1/2 61 30-1/2 2734

V908A 8 93-5/8 34-1/2 61 33-1/2 3071

V909A 9 105-5/8 34-1/2 61 37-1/2 3452

V910A 10 111-5/8 34-1/2 61 40-1/2 3809

V911A 11 117-5/8 34-1/2 61 43-1/2 4120

V912A 12 123-5/8 34-1/2 61 46-1/2 4447

* Width can vary with gas train conguration.

If the V9A packaged boiler must pass through a 36” doorway, please

specify.

** Add 6-1/2” to dimension C when equipped with optional top outlet.

*** Varies slightly with burner and gas train conguration.

1. Do not tilt. Exercise caution when lifting to avoid damage.

2. This boiler can be lifted by fork truck. Do not truck from front.

3. When lifting from rear, forks must extend beyond center of gravity and second skid

cross bar.

4. When lifting from side, forks must extend to opposite skid rail and straddle center

of gravity.

5. Cable spreader is to prevent jacket damage. Spreader width should equal B (width

of skid) + 12”. Adjust cable lengths to lift at approximate center of gravity per chart.

Figure 22: Shipping Information

Loading...

Loading...