16

8. FILLING THE HEATING INSTALLATION

Table 5

Problem Prevenon

Possible installaon damage due

tostrainsinthematerialcausedby

temperaturedierences.

Fill the heang installaon only in cold condions (inlet

temperaturemustnotexceed40°C).

Dangerofinstallaondamagedue

toaccumulaonofdeposits

Condensate formaon and tar

deposits may shorten boiler’s

operaonallife.

- Donotoperatetheheangboilerforalongperiodofme

inparalloadmode

- Thetemperatureattheboilerinletmustnotbelessthan

65°C,boilerwatertemperaturemustbebetween80and

85 °C.

- Usetheboilerforashortperiodtoheatwarmwaterinthe

summer.

9. BOILER OPERATION

9.1. Loadingtheboiler

Whenlighngtheboilerfortherstme,

a condensate is formed which is later

drained(thisisnotafaultintheboiler).

When burning moist wood, the boiler

stops working eecvely and fuel

consumpon increases signicantly,

desired output is not achieved and the

operaonallifeoftheboilerbodyandthe

chimneyisshortened.

Fuel is loaded in the upper combuson

chamberanditisrecommendedistoload

logs of length equal to the combuson

chamber length and stack them ght

insidewithleastpossibleairgaps.

Recommendations for fuel loading:

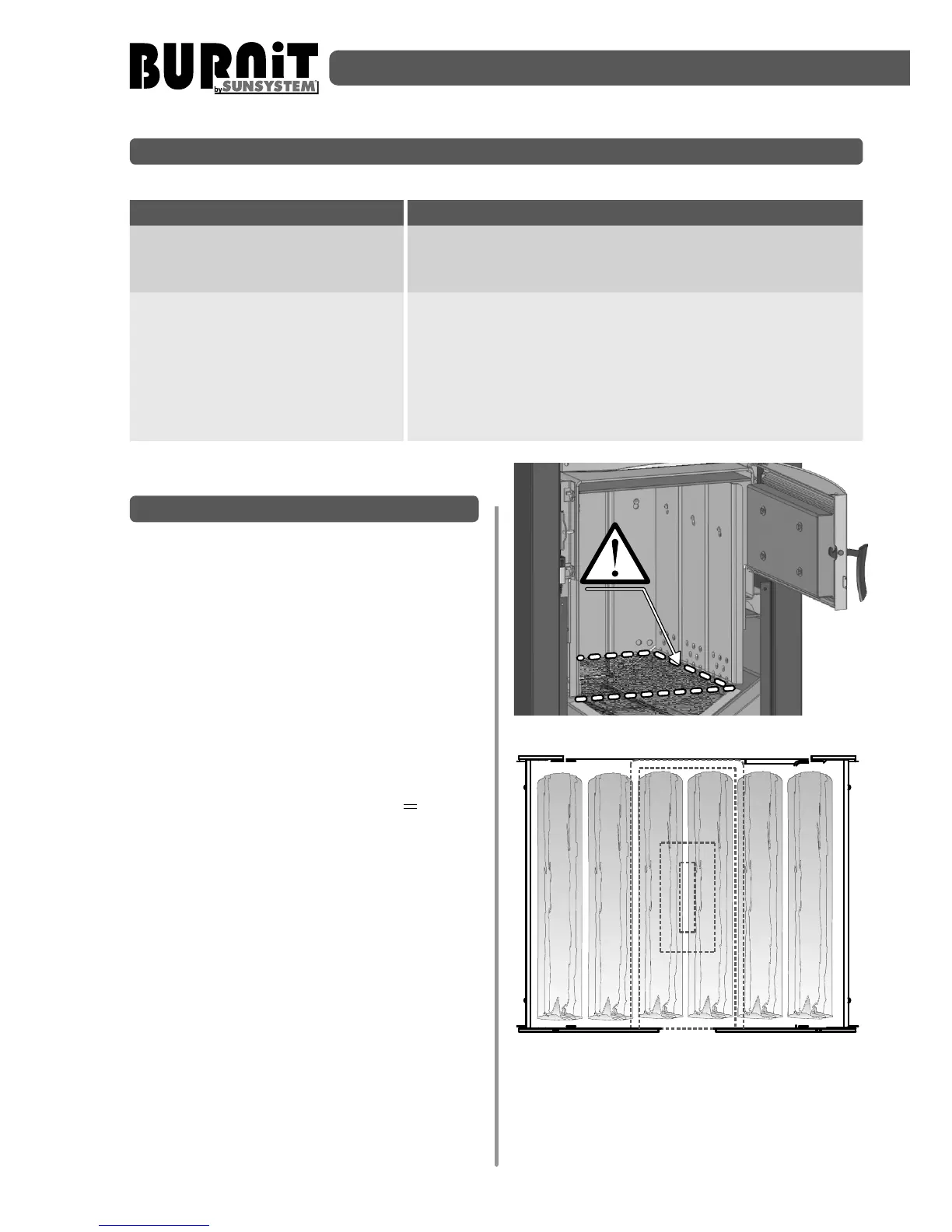

1. Keep air openings (upper chamber)

cleanfromash/Diagram10/.

Cloggingofairopeningsmayaffectboiler

operation.

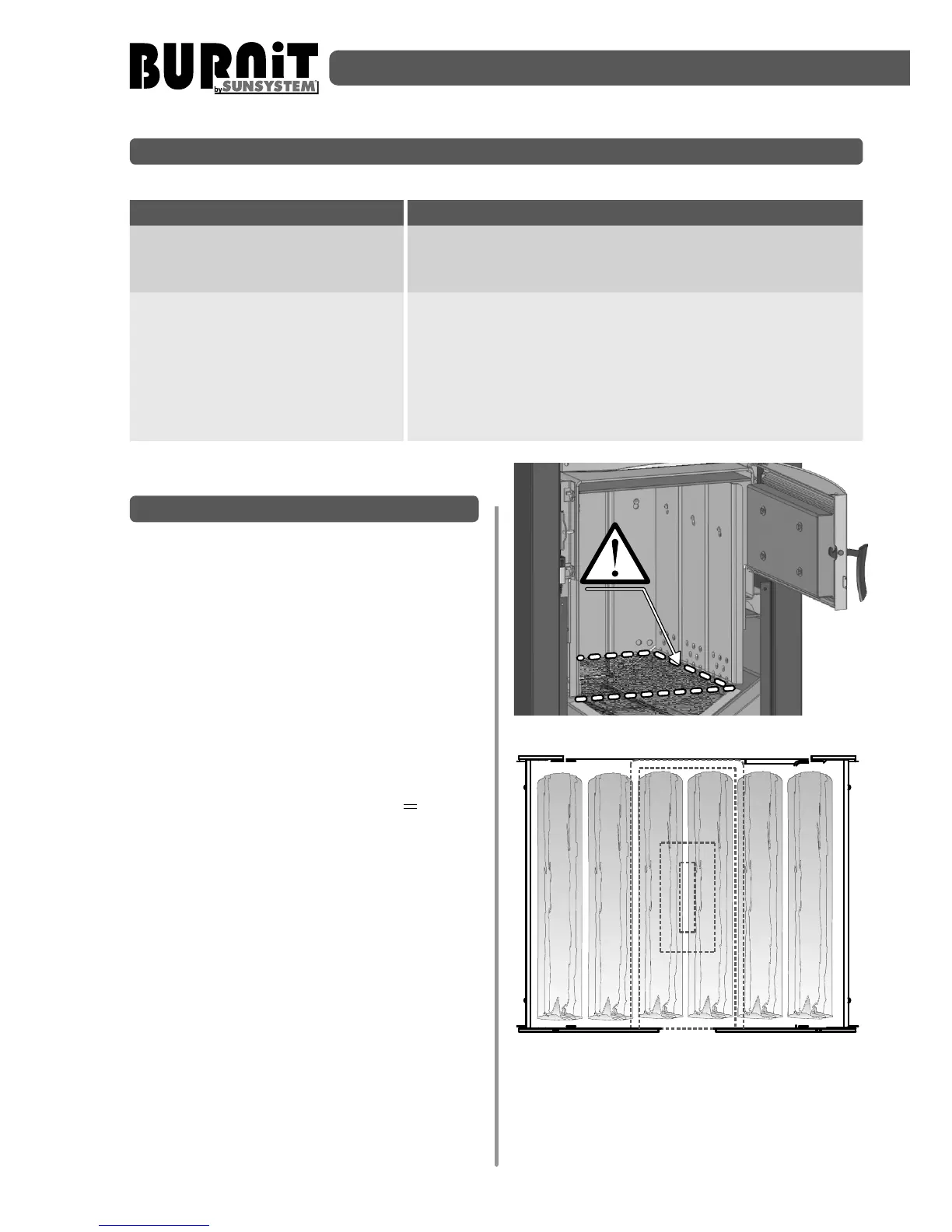

2.Stackingfirewoodinboilerchamber.

Wood in the chamber must be neatly

arrangedandnotthrown,asisillustrated.

This is a top plan view of the boiler

chamber/Diagram11/

Diagram 10

Diagram 11

An important condition for the smooth

runningofthepyrolysiscombustionisthe

upperchambertobewelltightwithfuel,

i.e. with minimal air gaps between the

woodpieces.

Loading...

Loading...