18

9.2 Combusonadjustment

Boom chamber door as well as all

inspecon openings must be closed and

sealed. Inside the boiler there should

notbeanyreorsmoke.Press F4keyto

start calibraon of lambda sensor. Over

a period of 2-3 min. the lambda sensor

is calibrated and can shi on to ignion

of the boiler. This calibraon is only

necessarybeforeigningtheboiler.Once

the boiler has entered work mode no

calibraonisrequiredbetweenreloads.

TostartignionoftheboilerpressF1 key

and load the boiler with the inial dose

of twigs and small wood, then kindle

them.Itisnecessarytomakeagoodglow

bedinorderthatrewoodloadedinthe

combusonchambersubsequentlymakes

a good re. During the glow-making

period it is necessary to hold the upper

doorslightlyopentoallowexhaustgases

be suconed through the slit in its top

part.Onceyouhavetheglowbedready,

top up with rewood to ll the enre

volumeofthecombusonchamber.

Thesuconfanintherearprovidesforthe

maintenanceofcombusonprocessinthe

boiler.Theinowoffreshairtotheboiler

is made possible by 2 aps operated by

motoractuators.Animportantcondion

isthataps bewellcentered beforethe

actuatorisfastenedtotherespecveap.

Sustainablecombusonprocessdepends

ontheproperadjustmentoftheapsand

thecorrectsengsofthecontroller.

9.3. Requirementsconcerningcleaning

andmaintenanceoftheboiler.

*

Cauon! Hot surfaces.

Before cleaning the boiler, make

sure the re in it has died out and

the boiler has cooled down.

9.3.1.Cleaning and maintenance by

customer.

-Exploitaon of the boiler and the type

ofusedfueldeterminehowoenhave

to clean the boiler residues from the

combusonprocess.

-Werecommendcleaningtheashesfrom

the upper chamber of the boiler to be

doneevery 3-4 days.Inthecasewhere

ashes has reached faster the level of

primary air openings, then ashes must

be cleaned immediately (see diagram

10). Do not let the ashes clog these

holes.

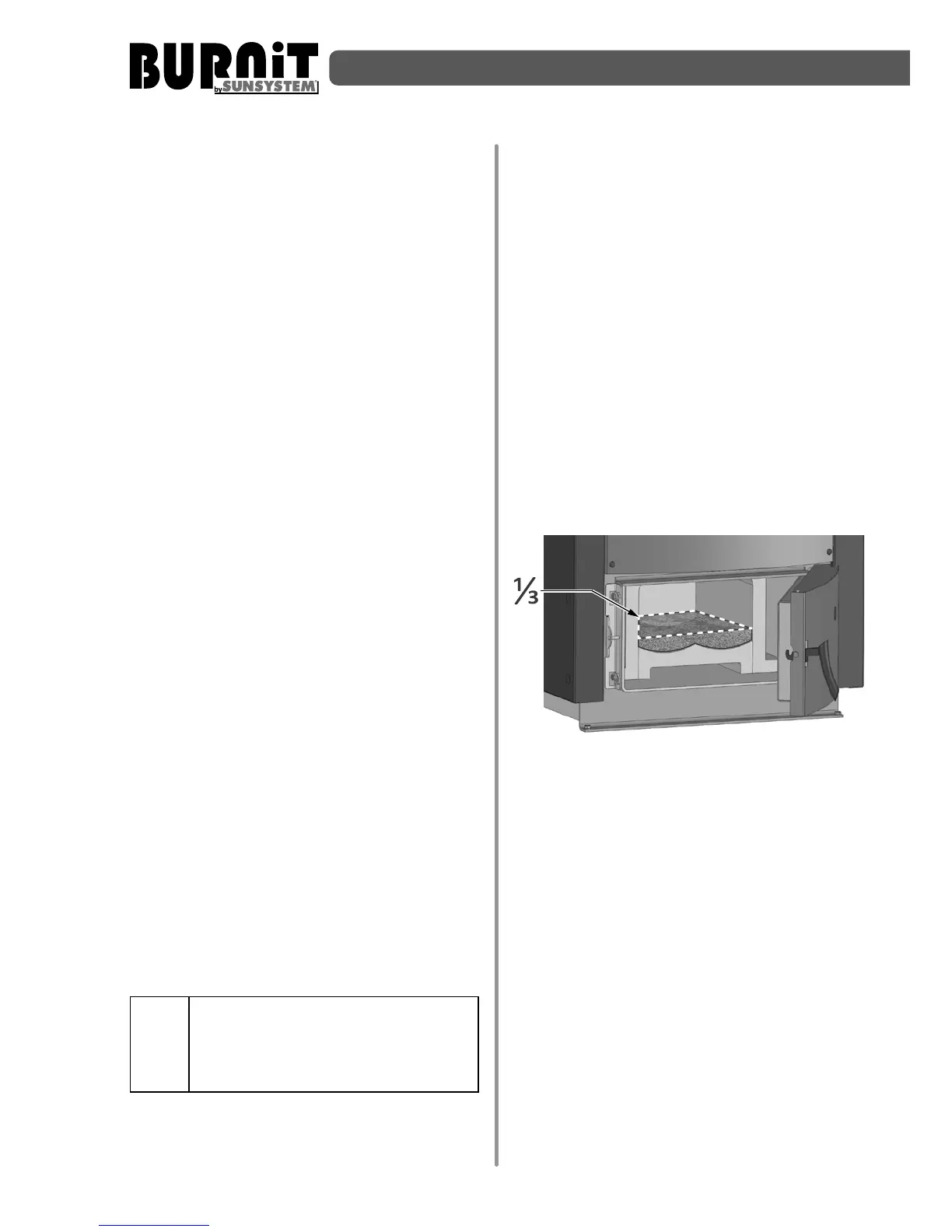

-The ashaccumulatesin lowerchamber

aswell.Cleanashwhenitslevelreaches

1/3oflowerchambervolume(Diagram

13). Uncleaned ash a ects boiler

operaon.

Diagram 12

9.3.2. Cleaning and maintenance by

authorizedinstaller/service

Boilercleaningandmaintenancemustbe

performedbyatechnician/serviceshop

authorized for such operaons. Before

the beginning of heang season must

be done inspecon and maintenance of

followingboilerparts:

1. Adjustment of boiler doors again.

Make sure the doors seal well. If

necessary, replace insulaon rope at

the door with a new one. Make sure

that the new insulang rope is placed

correctly,following exactlythegeometry

ofchannel.Pulltheropewelltothedoor

cornersbyusingascrewdriver.

Loading...

Loading...