20

•Thoroughlycleanthelowerchamber.

•Assemble the ceramic elements back

intothelowerchamberinreverseorder

– back (5), both sides (3 and 4) and

boom(2and1).

5. Cleaning of fume exhaust tubes of

boiler.

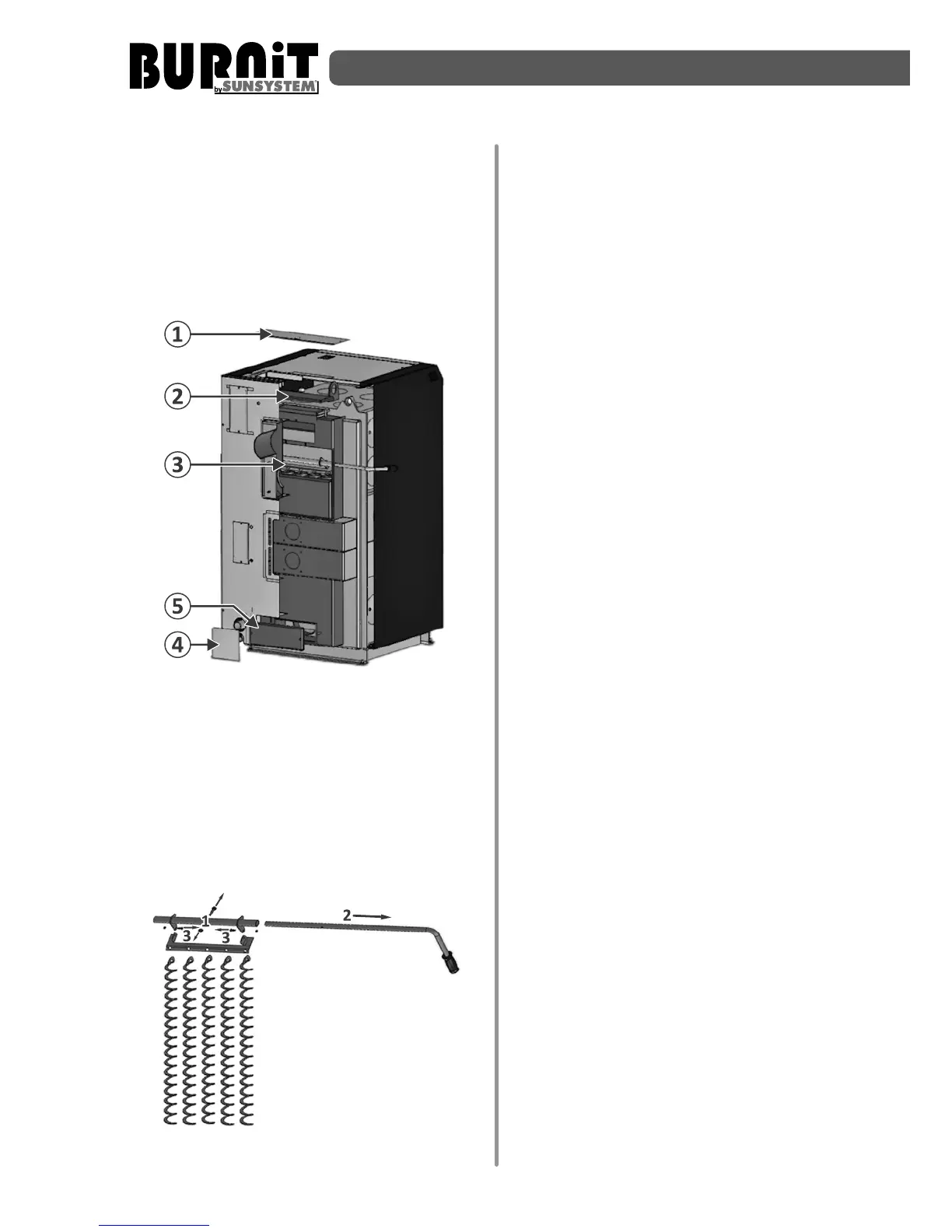

Diagram 16

•Uppercleaningopeningislocatedontop

ofboiler.Itisprotectedbytwocovers.

Unscrewthetwowingnuts.Disassemble

the decorave lid of upper cleaning

openingonboilercasing(1)

•Unscrewthetwowingnuts.Disassemble

the lid of upper cleaning opening on

boilerbody(2)

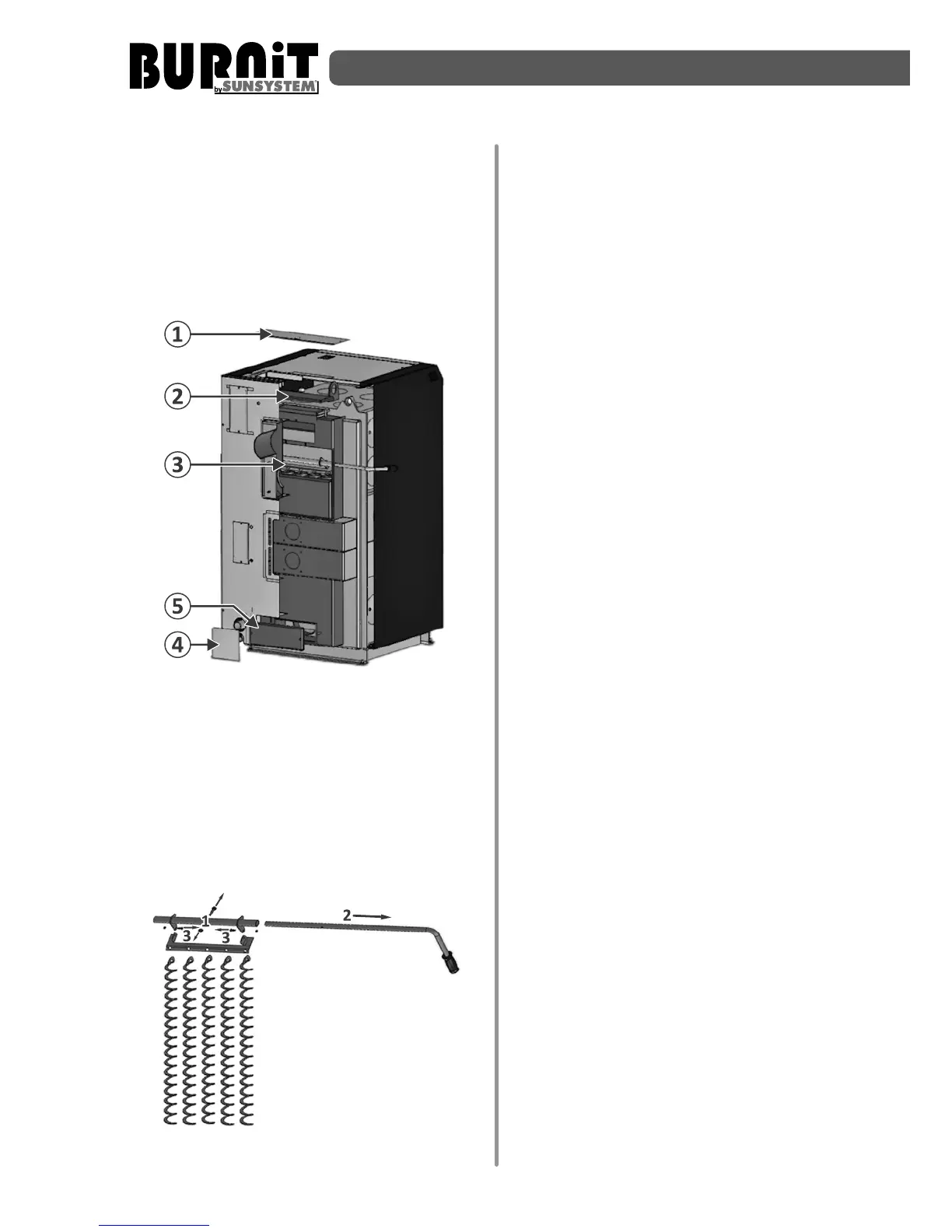

Diagram 17

•Remove the cleaning system (diagram

17) using a wrench S13 and S7.

Thoroughly clean fume exhaust tubes

(3)ofsootdeposits.Usethebrushfrom

equipmentdelivery.

•Lowercleaningopeningislocatedbehind

theboiler,lowdown.It isprotectedby

twocovers.Unscrewthetwowingnuts.

Disassemblethedecoravelidoflower

cleaningopeningonboilercasing(4)

•Lower cleaning opening. Unscrew

the two wing nuts. Disassemble the

decoravelidoflowercleaningopening

onboilercasing(5).

•Remove soot accumulaon aer the

cleaningoffumeexhausttubes

•Assemble the lid of upper cleaning

opening on boiler body (2). Make sure

thelidisplacedcorrectlyandght.

•Assemble the decorave lid of upper

cleaningopeningonboilercasing(1).

•Assemble the lid of lower cleaning

opening on boiler body (5). Make sure

thelidisplacedcorrectlyandght.

•Assemble the decorave lid of lower

cleaningopeningonboilercasing(4).

9.4. Important recommendaons for

long-lasngandcorrectoperaonofthe

boiler

•Pleaseperformperiodicmaintenanceof

the boiler as described in instrucons,

secon9.2.

•Theallowedmoisturecontentofthefuel

usedmustnotexceed15%÷20%.

•Gas emission in the combuson

chambermayresultintheformaonof

tar and condensate (acids). Therefore,

a mixing valve must be installed and it

mustbeadjustedsothattheminimum

temperature of the water returning in

the boiler is 65°С. This extends the life

spanoftheboileranditswarranty.The

operang temperature of the water in

Loading...

Loading...