combusonprocessmanagement

• Fuel loading door

• Cleaningdoor(combusonchamber)

• Actuator-drivenairapsforairintake

management

• STB–emergencythermostat

• Flue gas sensor

• Safetyheatexchanger.

• Open door sensor and fume

extraconopening

• Safetydevicesoftheboiler

Theboilerisequippedwith4independent

overheangprotecons.

1.Uponreaching95°Сthecontrollerturns

thefanoandacvatesthepumpsfor

domeschotwaterandheangsystem.

2.An independent STB thermostat shuts

downthefanuponreaching99°С.

3.Emergencycoolingcoilintegratedinthe

top secon of the water jacket allows

theconneconofthermostacvalve.

4.Safetyvalve3bar

3.FUELS

Theheangboilercanulizeonlynatural

and untreated wood. Log length should

be up to 500 mm. Pressed fuels and

briqueescontainingonlywoodmayalso

beused.Fuelmoisturecontentmustnot

exceed15-20%.

For maximum ulizaon of the wood

heang value we recommend to use

wood which has dried over a period of

1.5-2years.Highmoisturecontentofthe

wooddecreasesitsheangvaluewhichin

turnreducesboileroutput.

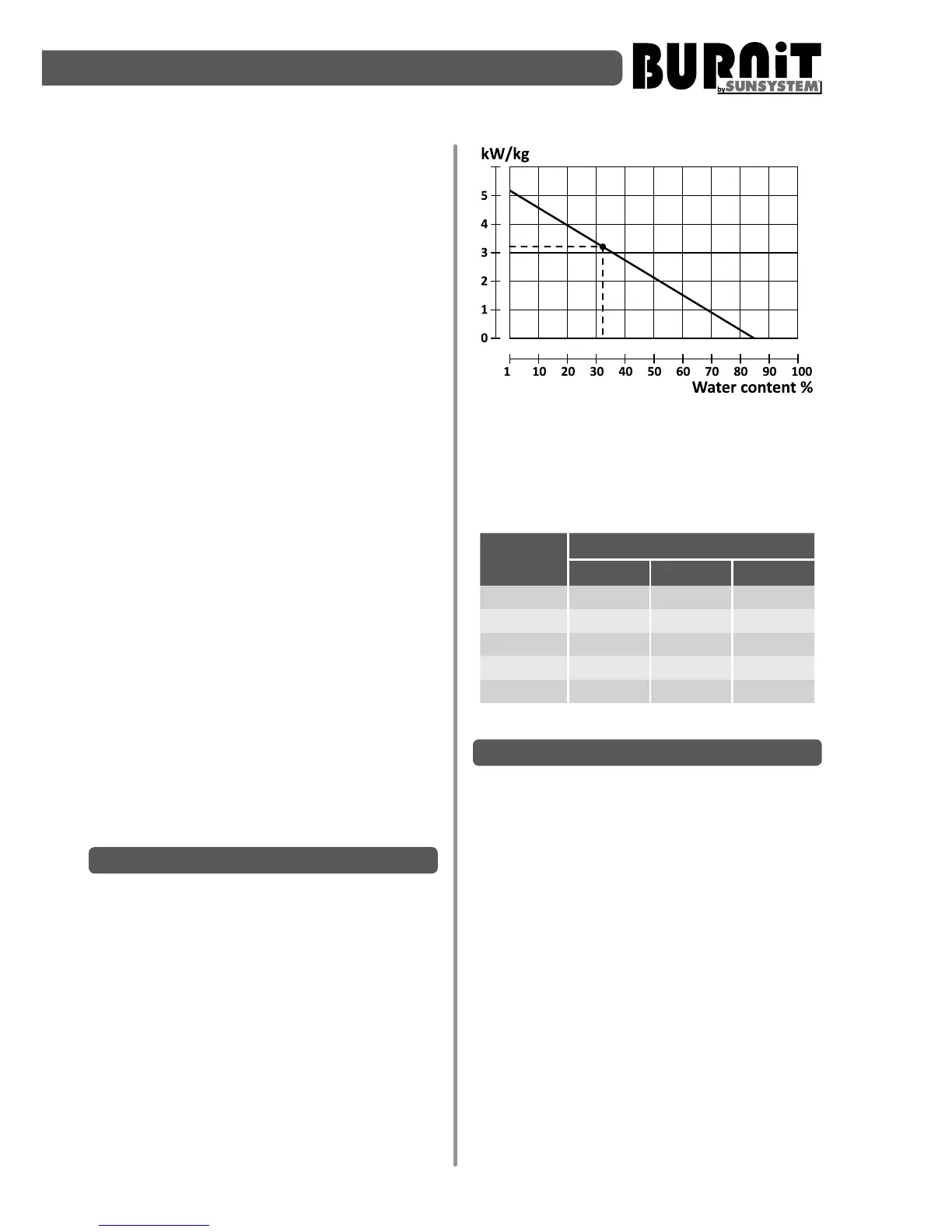

Diagram 2

Relaon between wood heang value and

water content.

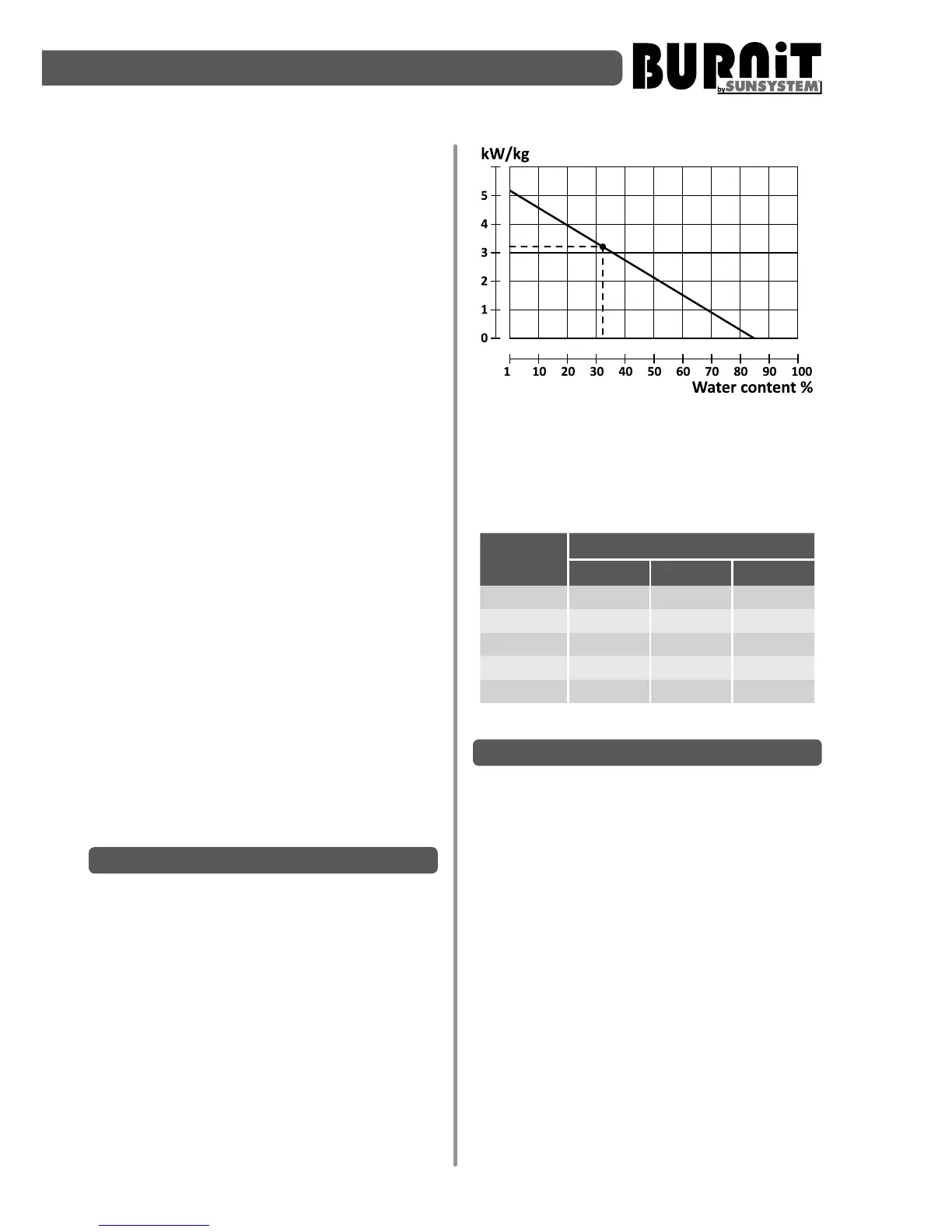

Table 2

Heang value of the most common wood

species

Wood

species

Energy contained in 1 kg

kcal kJoule kWh

Spruce 3900 16250 4,5

Pine 3800 15800 4,4

Birch 3750 15500 4,3

Oak 3600 15100 4,2

Beech 3450 14400 4,0

4. TRANSPORTATION OF THE BOILER

Werecommendtotransporttheheang

boiler to the installaon site in its

packaging placed on the pallet. During

transport and installaon, depending on

theweight,suitablesafetydevicesshould

be used in accordance with Direcve

2006/42/EC.

When transporng itemsweighing more

than 30 kg, the use of pallet jack, fork

truckorotherhoisngdevicesisamust.

Theboilerissafelysecured bymeansof

anchorngstoawoodenpalletofsizes

А,B,C.Ithasthenbeenstretch-wrapped

to protect the housing from scratching

anddustbuildup.Thelastelementofthe

packingisaheightDcardboardbox.The

cardboard box protects the boiler from

ambientcondionsduringtransport.

Loading...

Loading...