12

9 FREEZE PROTECTION

• Appliance installations are not recommended outdoors in areas where danger of freezing exists

unless precautions are taken. Maintaining a mixture of 50% water and 50% propylene glycol is

the preferred method of freeze protection in hydronic systems. This mixture will protect the

appliance to approximately -35ºF (-37ºC). To maintain the same temperature rise across the

appliance increase the GPM flow by 15% and the head loss by 20%.

The following example demonstrates the procedure to follow for calculating the revised head for the heat

exchanger when using a water / glycol mixture.

• Given for example that Camus is showing a heat exchanger flow and head loss of 100 gpm @ 10

feet

• Increasing the flow by 15% now results in a head loss of 13 feet at 115 gpm (from B&G system

syzer). At this increased flow Camus now recommends to increase the head loss by 20%.

• The requirement for the heat exchanger with water / glycol mixture will now be 115 gpm @ 15.6

feet. (ie. 1.2 x 13ft. = 15.6 ft.)

• A similar procedure must be followed to calculate the additional head loss in pipe and fittings in

order to arrive at the proper pump selection.

• For Outdoor installations a snow screen should be installed to prevent snow and ice accumulation

around the appliance. Regular inspections should be made to ensure that air intake and vent are

free of snow and ice. Always consider the use of a shelter such as a garden shed in lieu of direct

exposure of the appliance to the elements. The additional protection afforded by the shelter will

help to minimize nuisance problems with electrical connections and will allow easier servicing of

the appliance under severe weather conditions.

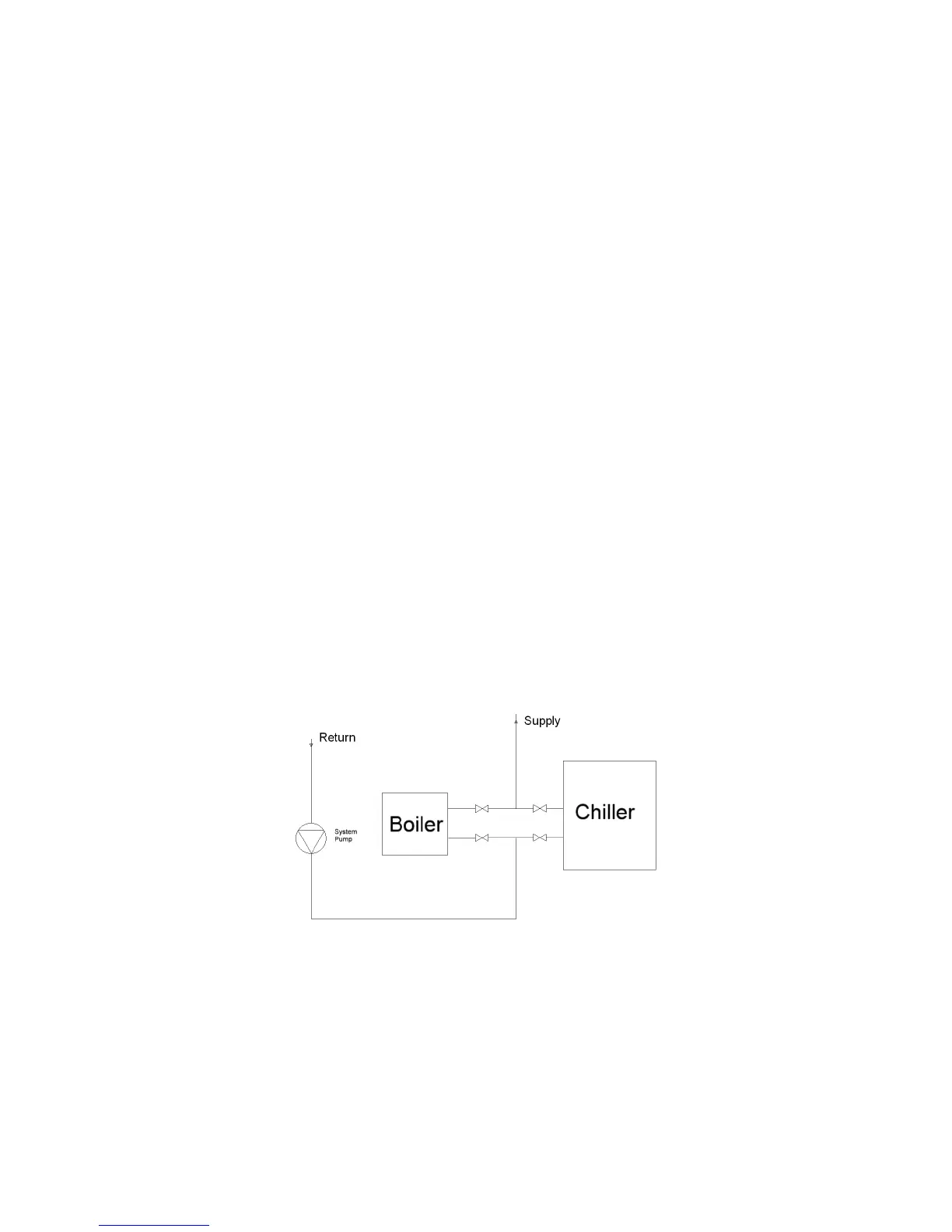

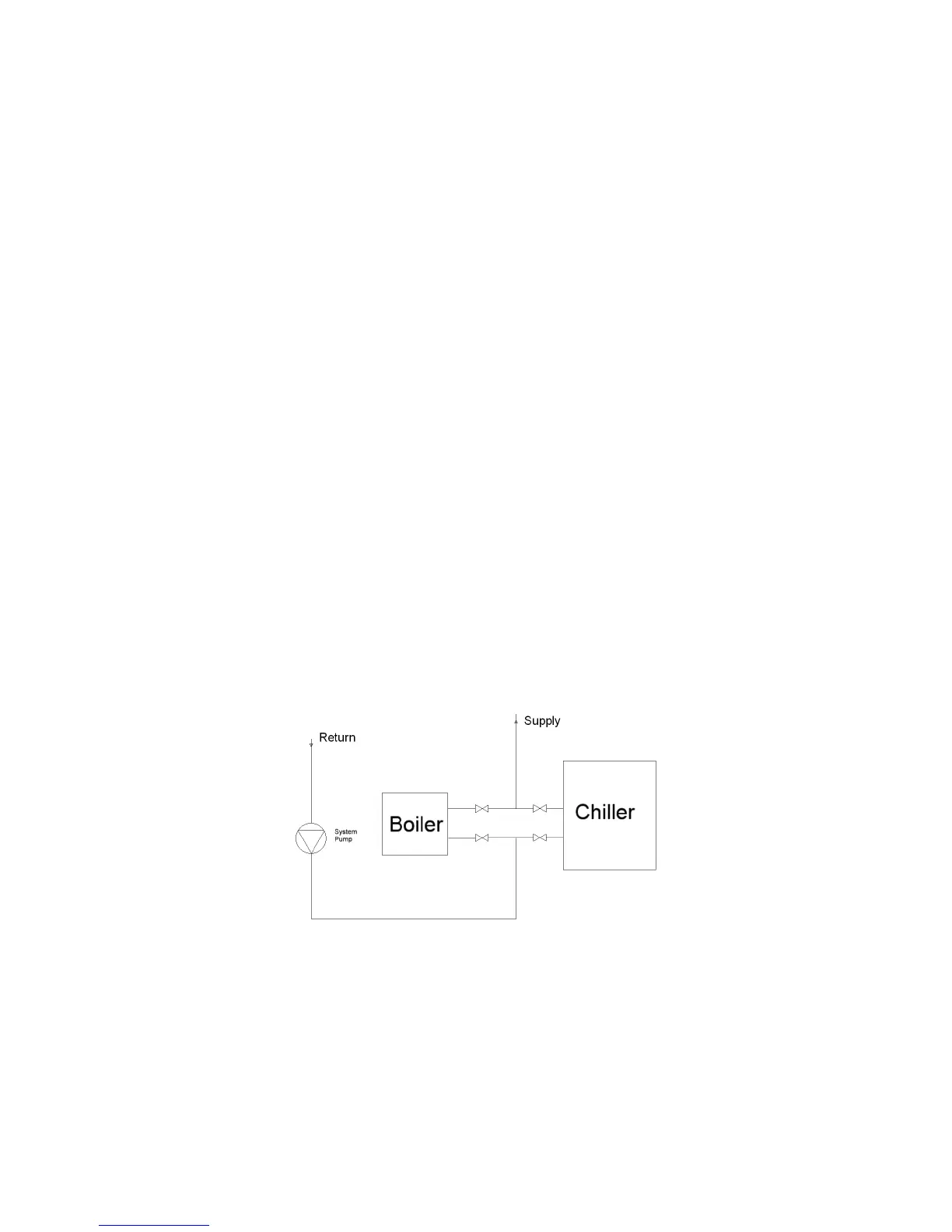

10 WARNING REGARDING CHILLED WATER SYSTEMS

When a boiler is connected to an air conditioning system where the same water is used for heating and

cooling, the chiller must be piped in parallel with the boiler. Appropriate flow control valves; manual or

motorized must be provided to prevent the chilled water from entering the boiler. (See Figure 4)

Figure 4: Typical Chilled Water System

When a boiler is connected to heating coils located in air handling units (where they may be exposed to

refrigerated air circulation), the boiler piping system shall be equipped with a flow control valve or other

automatic means to prevent gravity circulation of chilled water through the boiler. Chilled water in the

boiler will create condensate on the boiler tubes, which will collect in the combustion chamber causing

corrosion.

Loading...

Loading...