Chapter 4

4-56

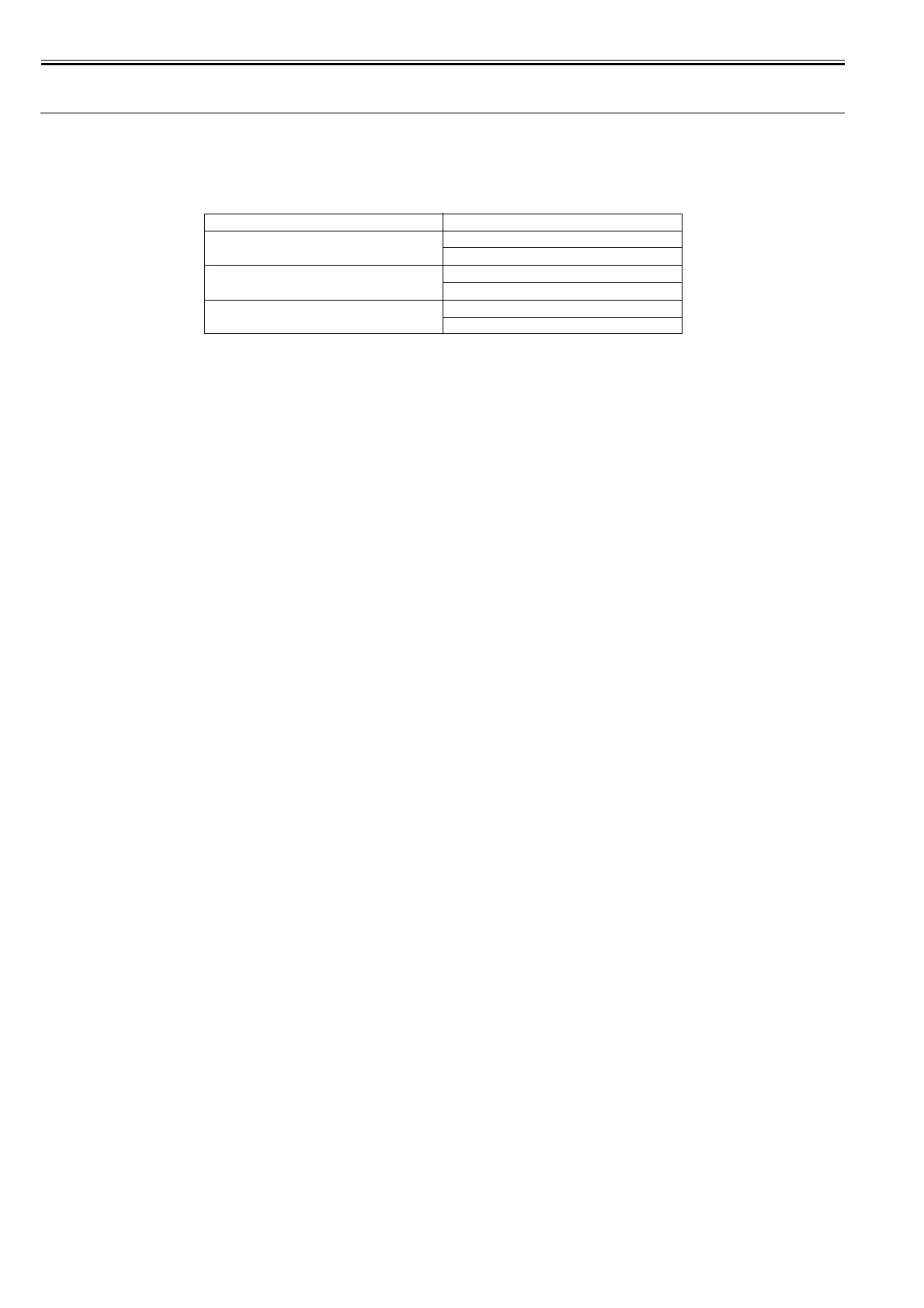

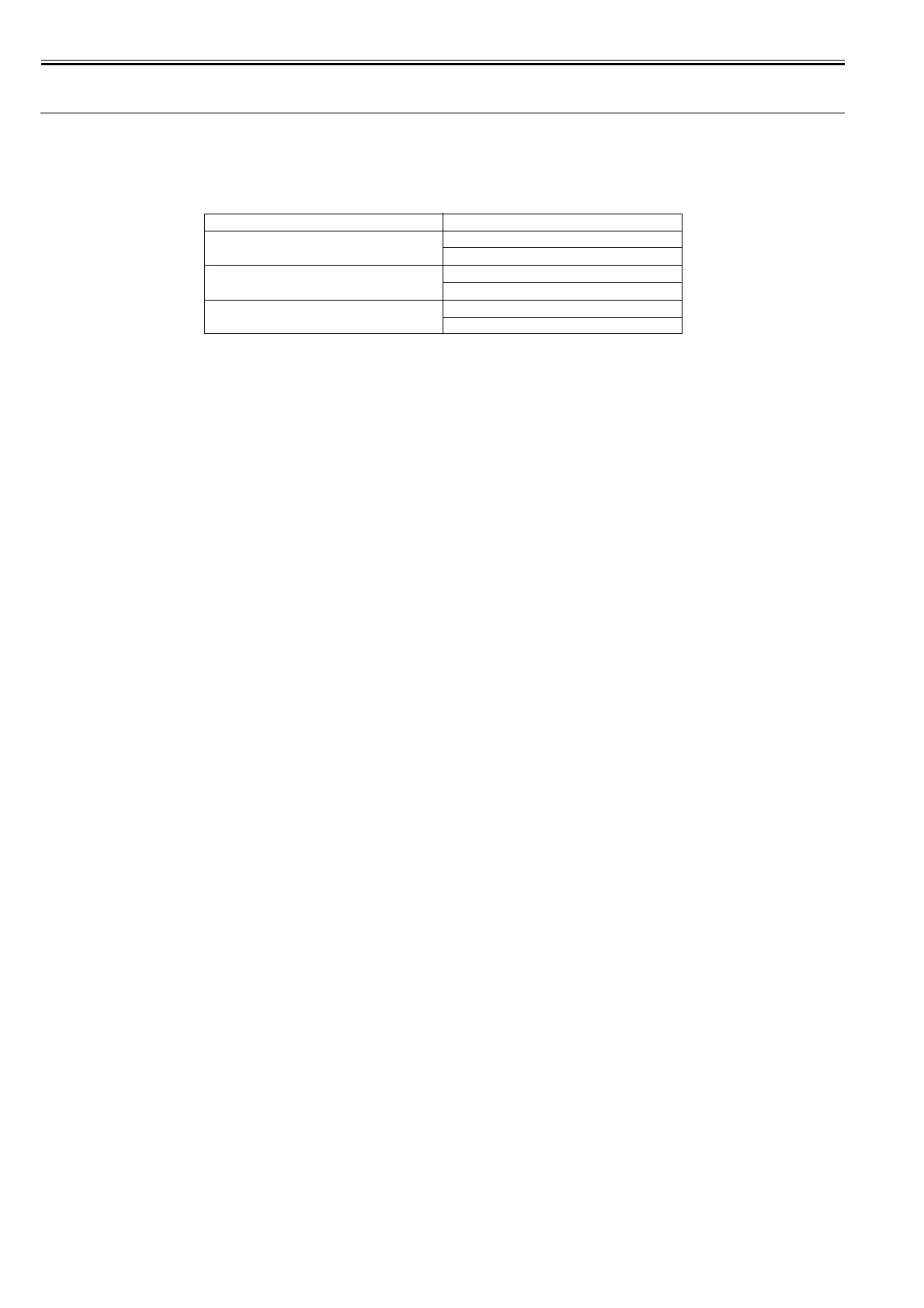

4.5 Adjustment and Setup Items

4.5.1 Adjustment Item List

0017-8323

The following adjustment procedures need to be performed when parts have been replaced or remove and then reinstalled:

T-4-2

4.5.2 Procedure after Replacing the Carriage Unit or Multi Sensor

0020-5714

a) Note on replacing the carriage unit and the multi sensor

The multi sensor reference plate(QL2-2840: MOUNT, MULTI SENSOR REFERENCE) must be replaced at the same time whenever the carriage or the multi sen-

sor is being replaced.

b) Multi Sensor Recalibration

Because the distance between the multi sensor (in the carriage unit) and the nozzles (in each printhead) is varied from one unit to another, the printer has its optical

axis corrected and paper gap adjustment sensor gain and calibration adjusted prior to shipment. When the carriage unit or multi sensor has been replaced, they

should require adjustment.

Execute service mode under the following conditions to launch automatic adjustment:

1) Carry out the following service mode without media loading.

- Service mode : SERVICE MODE > ADJUST > GAP CALIB.

2) Load the following media.

Media type : Photo glossy paper

Media size : Media having a width equal too larger than that of A2-size paper

3) Carry out the following service mode.

- Service mode : SERVICE MODE > ADJUST > PRINT PATTERN > OPTICAL AXIS

4.5.3 Procedure after Replacing the Feed Roller or Feed Roller Encoder

0032-0782

Feed roller eccentricity is factory-adjusted (correction of variation in the paper feed amount per rotation). It is necessary to adjust feed roller eccentricity after re-

placing the feed roller or feed roller encoder.

In the service mode, perform automatic adjustment of feed roller eccentricity.

Service mode : SERVICE MODE > ADJUST > PRINT PATTERN > LF TUNING

- Media type: Photo glossy paper

- Media size (width): 36 inches or wider

If adjustment cannot be done properly by selecting "SERVICE MODE > ADJUST > PRINT PATTERN > LF TUNING" (auto adjustment), carry out manual ad-

justment.

Service mode : SERVICE MODE > ADJUST > PRINT PATTERN > LF TUNING2

- Media type: Photo glossy paper

- Media size (width): 36 inches or wider

Check the printed pattern and enter values for adjustment.

4.5.4 Procedure after Replacing the Head Management Sensor

0013-7146

Since the distance between the head management sensor and the carriage unit varies among printers, the optical axis is factory-adjusted to adjust the non-discharging

detection position. When you have replaced the head management sensor or performed assembly/reassembly of surrounding parts that can change the distance be-

tween the head management sensor and the carriage unit, readjustment is required.

Perform the readjustment in the service mode.

Service mode : SERVICE MODE > ADJUST > NOZZLE CHK POS.

Adjustment item Adjustment timing

Multi sensor recalibration Multi sensor replacement/removal

Carriage unit replacement/removal

Adjusting feed roller eccentricity Feed roller

Feed roller encoder

Head management sensor recalibration Head management sensor replacement/removal

Carriage unit replacement/removal

Loading...

Loading...