23

ENG

“compactsteam” +0300092IE - rel. 1.2 - 14.01.2021

4. STARTING

IMPORTANT WARNINGS:

Before starting:

1. check that the humidier is in perfect condition,

2. make sure there are no water leaks and that the electrical components

are dry.

Do not connect the power supply if the humidier is damaged or even

partially wet!

When installation is completed, ush the supply hose for around 10

minutes by piping water directly into the drain, without sending it into

the humidier; this will eliminate any scale or processing residues that

may cause foam when boiling.

IMPORTANT: when starting the humidier with a new or empty

cylinder, it may take some time (several hours) for the water to reach a

sucient concentration of minerals as to allow nominal steam production.

4.1 Checks when starting

Before starting the humidier, check that:

• The water supply is connected, the line has been ushed and the taps are

open.

• The drain is connected as explained in the paragraph 3.5 (ood prevention

funnel and drain trap under the unit).

• The power supply is connected in accordance with the instructions, the

laws in force and the rating labels on the unit.

• The power fuses are installed and intact.

• Any air ow switch is wired to open if there is no air ow.

• Any limit humidistat is wired to open if the humidity increases above the

set value.

• All the wire connectors on the unit are tight.

• The steam and condensate hoses are installed correctly, without kinks or

twisting, and are correctly sloped in compliance with the manual.

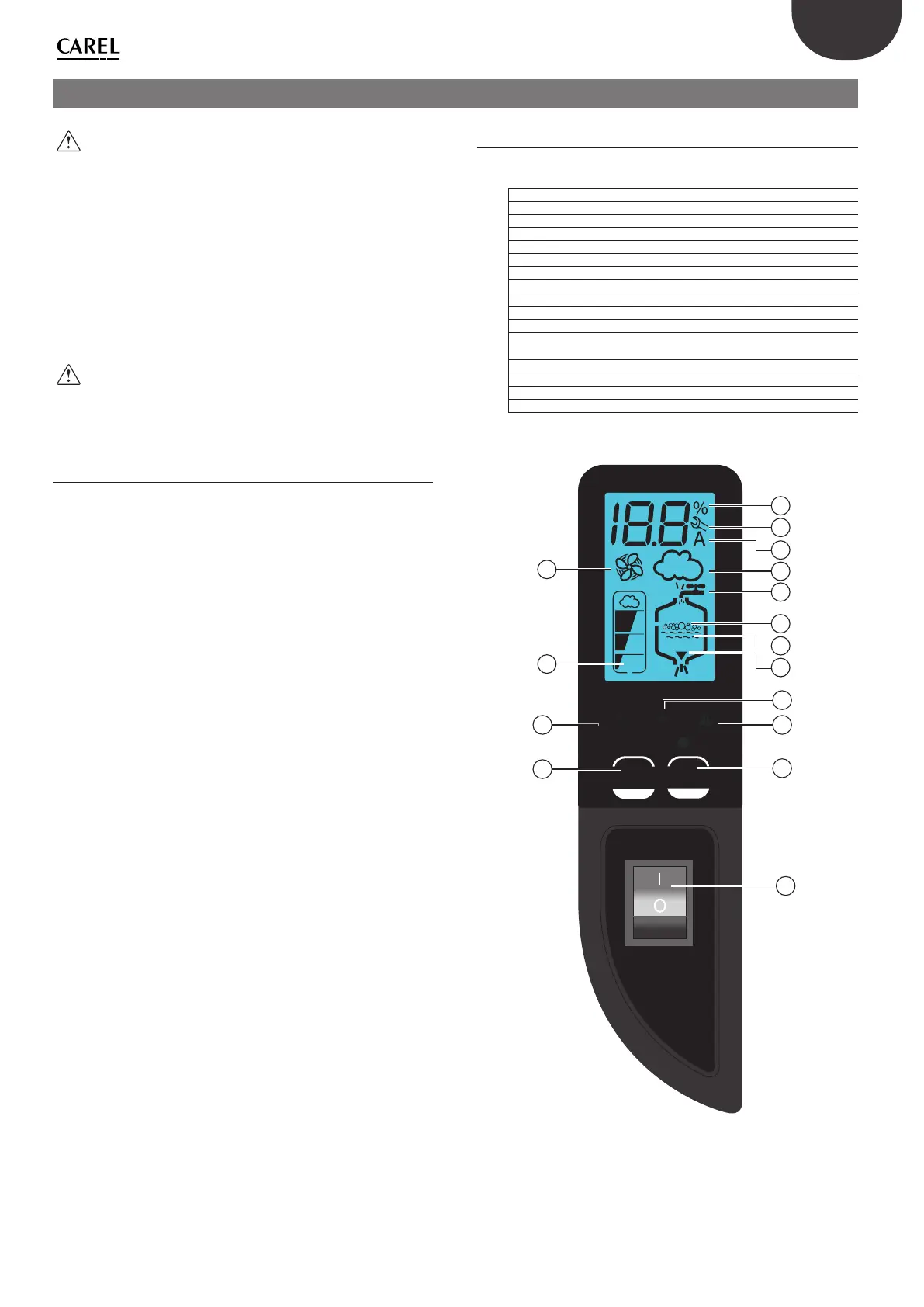

4.2 CompactSteam control device

The compactSteam control device features an LCD that, using icons and

numbers, displays the operation of the system:

1 Steam production as a % of rated capacity

2 Active alarm icon

3 Instant current ow in amperes (default display)

4 Steam production in progress

5 Cylinder ll in progress

6 Foam detected inside the cylinder

7 Water inside the cylinder

8 Cylinder drain in progress

9 Red LED: alarm

10 Yellow LED: power supply

11 Green LED: operation

12 Drain button for manually emptying the cylinder and conrming the

values set for the parameters

13 On/O button

14 “Reset” button to reset alarms and access the parameters

15 Level of steam production: 33%, 66%, 100%

16 Fan relay active

Tab. 4.a

sel

RESET

SEL

DRAIN

ENT

1

2

4

5

6

15

16

3

7

8

13

9

12

10

14

11

Fig. 4.a

Loading...

Loading...