9

ENG

“compactsteam” +0300092IE - rel. 1.2 - 14.01.2021

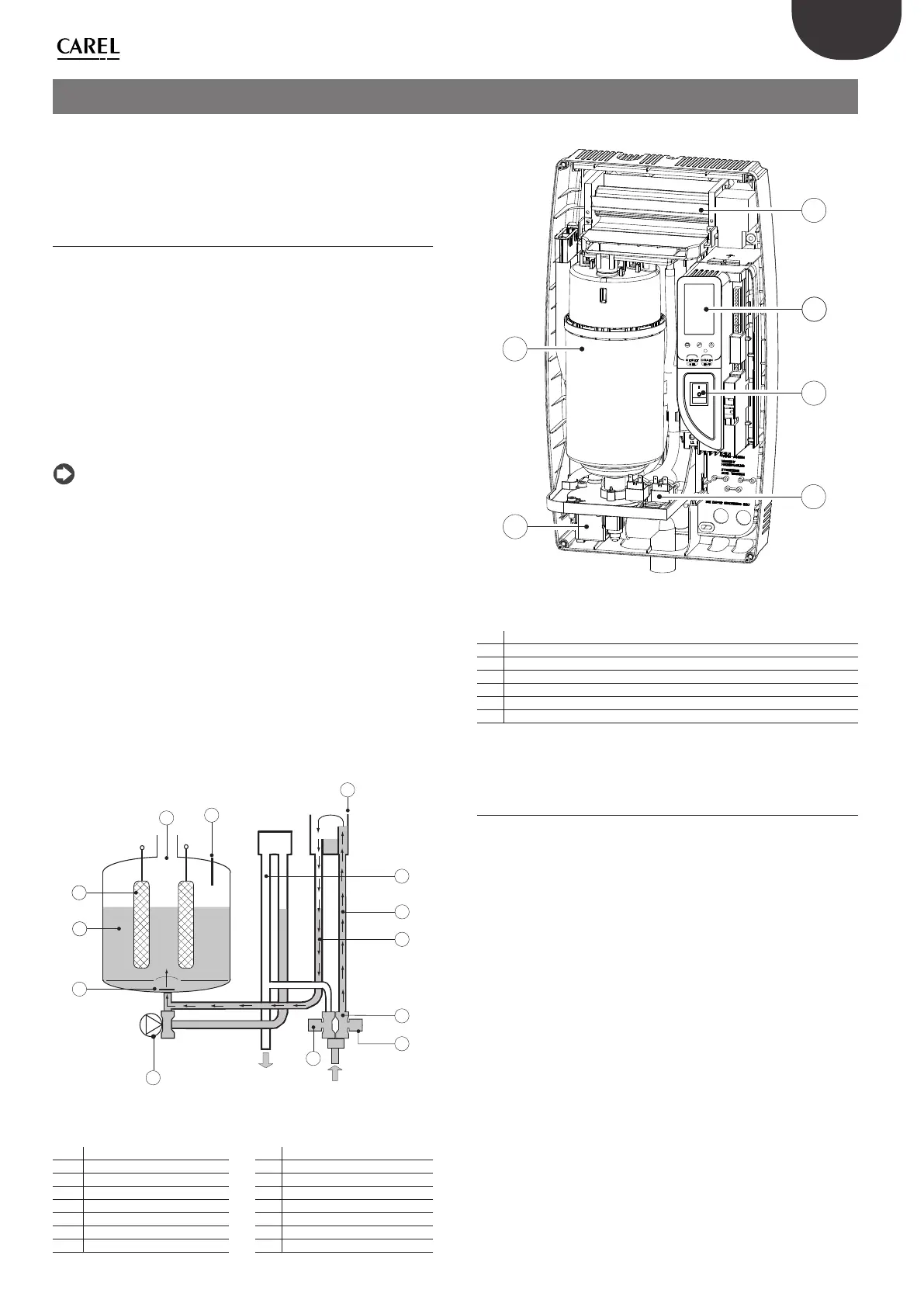

1. COMPACTSTEAM OPERATION

Range of isothermal humidiers for steam production in rooms. The

steam is produced from the water contained in the cylinder (connected

to the mains). The water boils and evaporates due to the electric current

generated by two immersed electrodes in the cylinder.

1.1 Operating stages

• the humidier opens the ll valve (1) connected to the main water

supply;

• the water ows through the hose (2) to the tank (3), the ow restrictor

(4) controls the lling speed;

• when the tank is full, the water overows into the hose (6) and starts

lling the cylinder (5);

• once the level of water in the cylinder has been reached, the humidier

closes the ll valve (1);

• the current generated by the immersed electrodes in the cylinder (7)

heats the water until it boils;

• the steam exits the cylinder through the outlet (8) and - depending on

the model of humidier - is distributed directly into the room (using a

fan), or into the duct (via a steam line).

Note:

• if the water in the cylinder exceeds the level sensor (9), the humidier

will activate the drain pump (11) and empty the excess quantity;

• if the current generated in the cylinder exceeds the required level, the

humidier will activate the drain pump (11) and discharge the amount

of water needed to restore the correct current;

• before emptying the humidier activates the tempering valve (10) to

cool the water to 60°C/140°F;

• the humidier automatically controls the quantity of mineral salts

dissolved in the water by activating the ll (1) and drain (11) pumps;

• the cylinder is tted with a lter (12) to prevent the mineral debris from

blocking the drain pump (11);

• if the humidier is in standby and does not produce steam for more

than 3 days (72 hours), the water in the cylinder is automatically

emptied;

• the ll tank (3) is connected to an overow hose (13) to prevent contact

between the mains water and the water in the cylinder;

• the current running through the cylinder is controlled by the current

transformer connected to the electrodes (7).

HL

DP

DT

EVF

7

12

5

10

1

4

6

2

13

13

9

8

11

Fig. 1.a

Key:

No. Description No. Description

1 ll valve 8 steam outlet

2 ll hose 9 level sensor

3 ll tank 10 tempering valve

4 ow restrictor 11 drain pump

5 cylinder 12 water drain lter

6 cylinder ll hose 13 overow hose

7 immersed electrodes

A

F

B

C

D

E

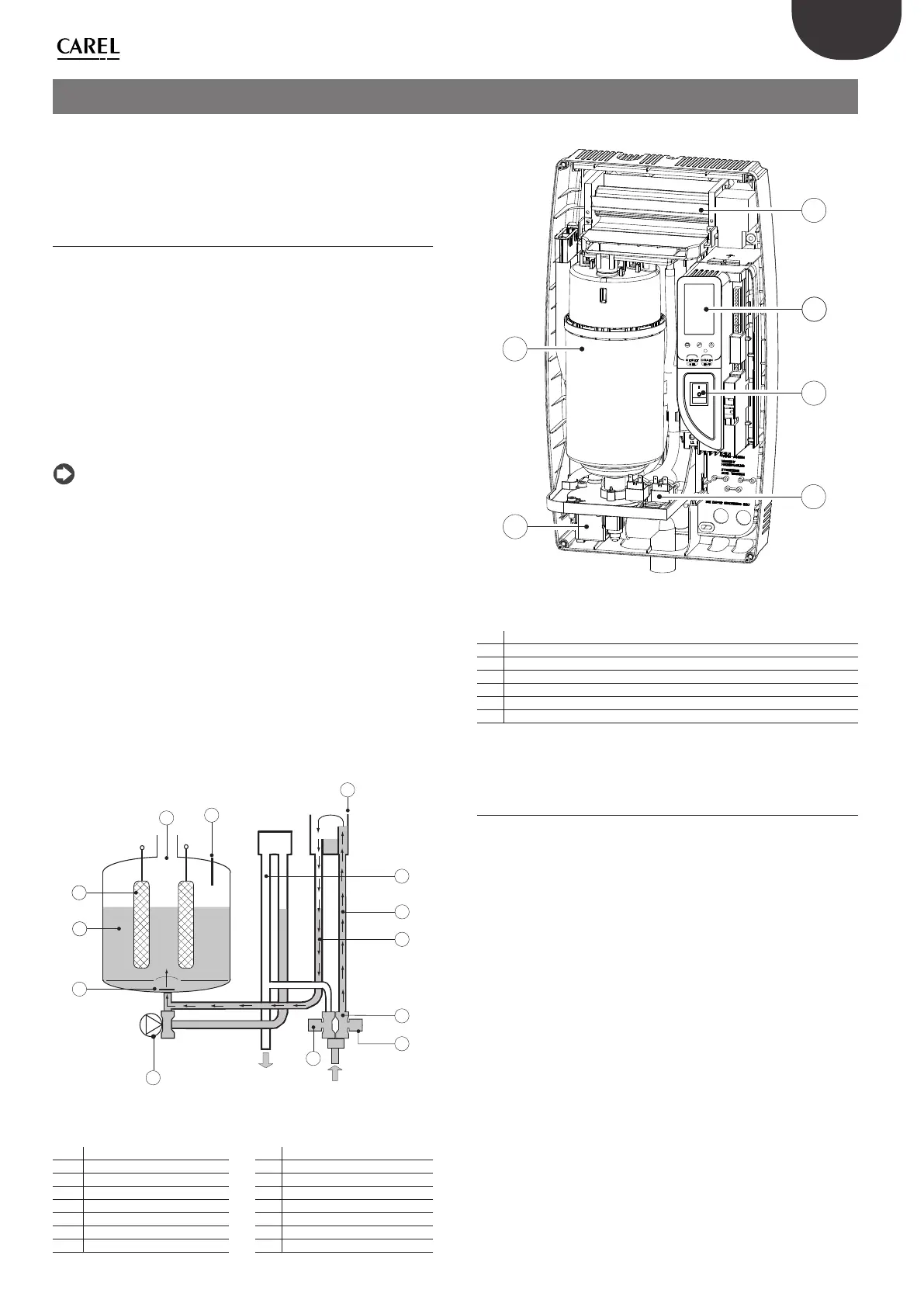

Fig. 1.b

Key:

No. Description

A Steam generator cylinder

B Steam blower (optional)

C User interface/display

D On/o button

E Fill and mixing valves

F Drain pump

1.2 Cylinder service life

Basic information

The plastic cylinder containing the electrodes is the most important

component of the humidier. During operation, the water in the cylinder

boils to produce steam. As the steam does not entrain any of the minerals

dissolved in the water, the concentration of such minerals will increase

the more steam is produced; moreover, some salts (especially calcium

and magnesium bicarbonates) tend to foul the electrodes, until these

become electrically insulated. As the electrodes become progressively

coated with scale, the water level in the cylinder is increased so that a

new portion of clean electrodes can conduct the current. Eventually, the

electrodes will be completely coated with scale and will no longer be

able to conduct the current needed to produce steam. The humidier

controller can detect when there is low current between the electrodes,

indicating the end of the cylinder’s service life; this is displayed by

alarm code E3. Several factors inuence cylinder service life (water

characteristics, such as hardness and quality, % of steam production); for

the part numbers specied in Table 8.a, the cylinder has a service life of

600 or more hours.

Water drain

Water ll

Loading...

Loading...